Komatsu PC80MR-3 Service Manual

Product Overview

The Komatsu PC80MR-3 service manual is an essential tool designed to enhance the quality of repairs by providing operators with a comprehensive understanding of the product. This manual guides you through the accurate methods for conducting repairs and making informed decisions. Utilize this manual fully during service operations for optimal efficiency and effectiveness. It is primarily intended for use in service workshops where technical operations are regularly performed.

Key Features

- Detailed Component Structure: Understanding the structure and function of each component, offering valuable insight for troubleshooting.

- Comprehensive Testing and Adjustments: Includes checks to be done prior to and following repairs, with charts for problem-to-cause correlations.

- Step-by-Step Disassembly and Assembly: Guides on the proper order and precautions for component removal, installation, disassembly, and assembly.

Benefits

- Enhanced Repair Quality: Equip yourself with the necessary technical knowledge to perform repairs to the highest standard.

- Improved Operational Efficiency: Streamline repair processes with clear and detailed instructions.

- Troubleshooting Assistance: Gain access to troubleshooting materials for more effective problem-solving.

Usage Recommendations

- Ensure a thorough understanding of all manual contents before beginning any service work for best results.

- Utilize the manual as a reference during all stages of repair and maintenance for the Komatsu PC80MR-3.

- Follow the structured guidelines and precautions provided to avoid errors and enhance safety.

The manual is divided into several chapters, each focusing on a main group of components, which are further categorized into practical sections:

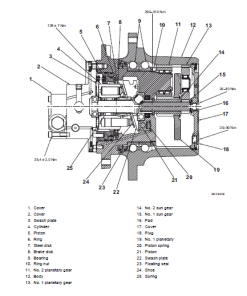

Structure and Function

This section elaborates on the structure and function of each component. It is designed not only to provide a comprehensive understanding but also to serve as a valuable reference for troubleshooting.

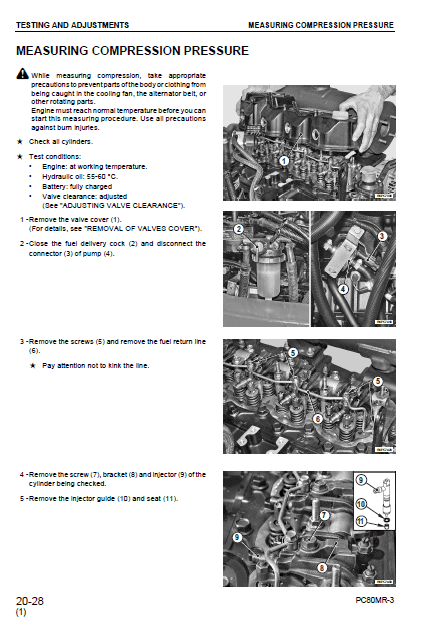

Testing and Adjustments

This segment covers the necessary checks before and after repairs, along with the required adjustments upon completion. It includes troubleshooting charts that connect various problems to their potential causes.

Removal and Installation

The manual offers detailed guidance on the sequence to be followed during the removal, installation, disassembly, or assembly of each component, along with the necessary precautions to be observed during these operations.

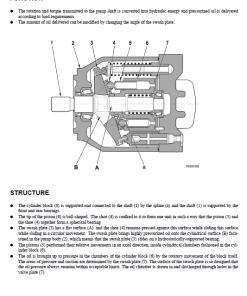

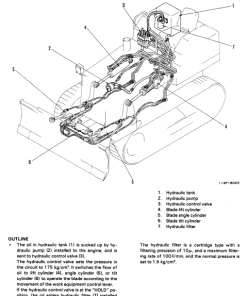

When traveling in a straight line, the system compensates for differences in oil flow between the left and right travel circuits. The junction circuit opens when both spools are activated, ensuring equal oil flow to the motors, thus preventing deviation. For steering adjustments, load pressure differences direct the travel valve adjustments, allowing precise navigation.

n

Operation Details

- Activating the travel spools redirects pump discharge flow from pump circuit PP and circuit PA to actuator circuit A.

- To maintain equal actuator circuit PA flow, the left and right reducing valves are symmetrically adjusted, opening the notch and travel junction circuit.

- This ensures interconnected travel circuits, compensating any oil flow differences to maintain straight-line travel without deviation.

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.