Komatsu SK1020-5 Skid-Steer Loader Service Manual

$34.00

Manual Included:

- Shop Manual: 250 and 256 pages

Specifications:

SKU: 894562

Categories: Komatsu, Skid-Steer

SK1020-5 Shop Manual

Product Overview

The SK1020-5 shop manual is an essential resource for improving repair quality by providing operators with a thorough understanding of product mechanics and guiding them through the correct processes for repairs and assessments. This manual is designed primarily for technical operations within a service workshop setting. It is structured into comprehensive chapters, each dedicated to a main component group, and further organized into detailed sections.

Key Features

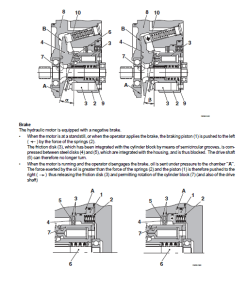

- Structure and Function: Explains the design and operation of each component, serving as a vital reference for troubleshooting and understanding the overall system architecture.

- Testing and Adjustments: Offers guidelines on necessary checks before and after repairs, adjustment steps post-repair, and troubleshooting charts correlating problems with their causes.

- Removal and Installation: Provides detailed procedures for the removal, installation, disassembly, and assembly of components, including precautionary measures.

- Standard Maintenance: Details judgment standards for inspecting disassembled parts, ensuring reliable maintenance practices.

Benefits

- Improves the efficiency and accuracy of repairs through clear, structured guidance.

- Reduces downtime by enabling quick troubleshooting and adjustments.

- Enables operators to perform maintenance with comprehensive reference information.

- Facilitates adherence to industry standards and best practices in component handling.

Usage Recommendations

- Ensure a complete understanding of the manual before performing any repairs.

- Refer to relevant sections while conducting specific tasks to maximize accuracy and efficiency.

- Regularly consult the troubleshooting charts for effective problem resolution.

Precautions During Installation

- Tighten nuts and screws using the specified torque settings.

- Install flexible hoses without entangling or twisting them.

- Bend cotter pins and stops securely.

- When using adhesives, clean parts thoroughly and apply adhesive uniformly on the threads.

- For liquid sealants, clean and inspect surfaces before application to ensure smooth operations.

- Clean all parts to remove dirt, rust, and burrs; apply engine oil on moving parts.

- Utilize anti-friction grease on pressure-assembled surfaces to prevent sticking.

- Ensure snap-rings are firmly seated after installation.

- For electrical jacks, clean off any contaminants before firmly connecting.

- Check eyebolts for distortion, screw fully, and align eye with hoist hook.

- Tighten flange screws in a crisscross pattern for even distribution.

Only logged in customers who have purchased this product may leave a review.

Related products

$33.50

$34.00

$34.00

$34.50

$27.50

Reviews

There are no reviews yet.