Komatsu SK1026-5, SK1026-5N Skid-Steer Loader Service Manual

$34.00

This comprehensive shop manual provides detailed guidance for the Komatsu SK1026-5 and SK1026-5N Skid-Steer Loaders. The manual includes clear instructions and specifications crucial for maintenance and repair.

SK1026-5, SK1026-5N Shop Manual

Product Overview

The SK1026-5, SK1026-5N shop manual is an essential tool designed to enhance the quality of repairs by providing detailed insights into the product. This manual ensures the user gains a comprehensive understanding of the components and assists in performing repairs accurately. Utilize this manual to maximize the efficiency and effectiveness of your maintenance tasks.

This manual predominantly contains crucial technical information crucial for operations conducted within a service workshop, organized into chapters focused on each primary group of components.

Key Features

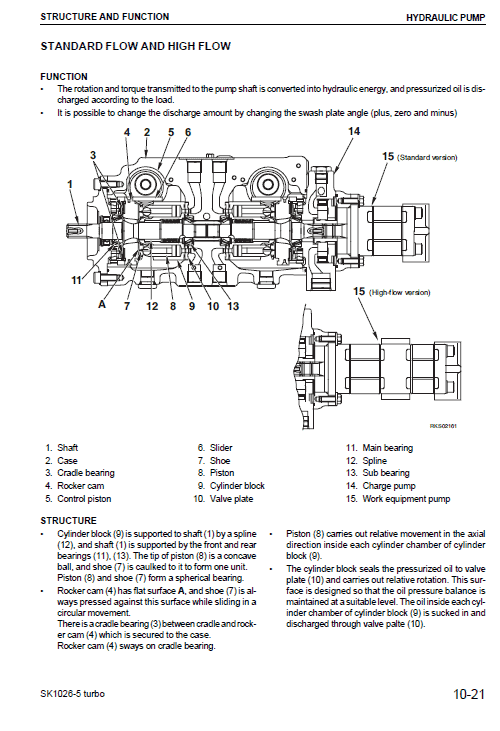

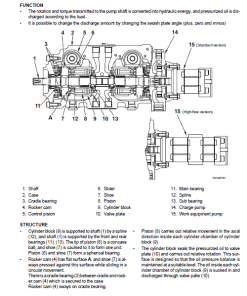

- Structure and Function: Provides a clear explanation of each component’s structure and function, serving as a valuable resource for troubleshooting.

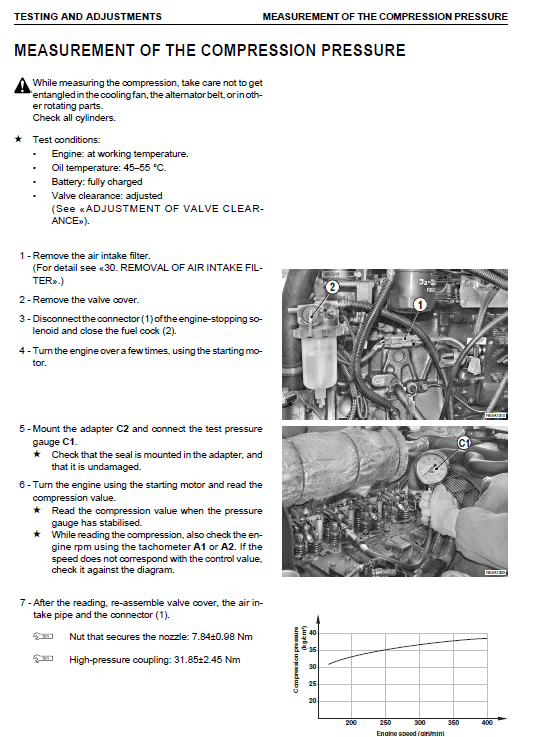

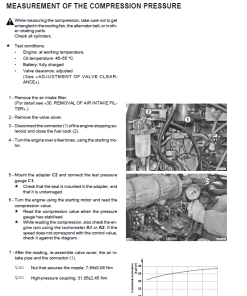

- Testing and Adjustments: Details the necessary checks before and after repairs, including adjustments post-repair. Includes troubleshooting charts that link potential issues with their causes.

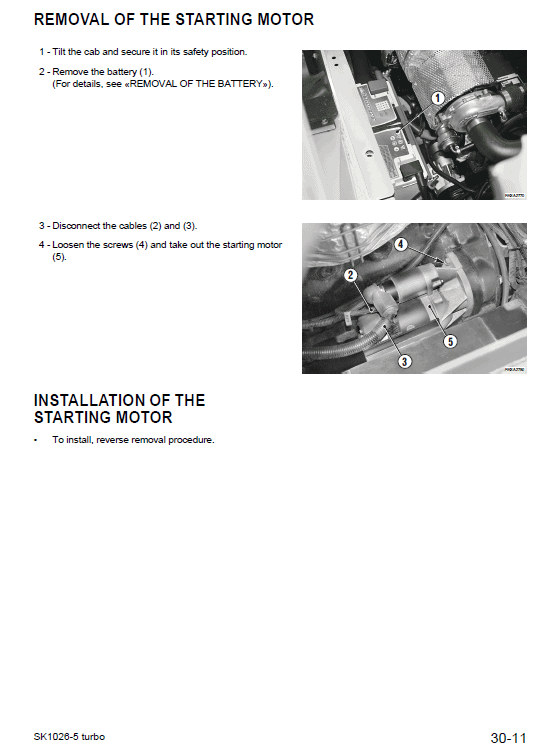

- Removal and Installation: Outlines the sequence for removing, installing, disassembling, or assembling components, along with necessary precautions.

- Standard Maintenance: Offers standards for evaluating disassembled parts during inspections.

Benefits

- Improves repair quality with detailed component understanding.

- Facilitates accurate troubleshooting and problem-solving.

- Ensures safe and systematic component handling.

- Maintains high standards of maintenance and inspection.

Usage Recommendations

- Thoroughly understand the contents for optimal use.

- Refer to this manual as a guide throughout maintenance and repair operations.

- Follow the structured approach for each chapter to enhance repair processes.

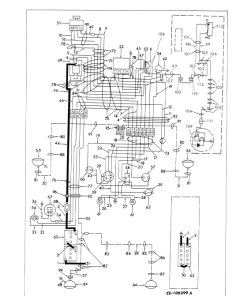

System Performance Test

This performance test evaluates the condition of all system components. Follow these steps for optimal results:

- Start the engine and operate it at 1200 to 1500 RPM.

- Position a fan in front of the condenser to simulate typical air flow and stabilize the system.

- Insert a thermometer into the air conditioning vent closest to the evaporator.

- Compare gauge readings against ambient temperature standards.

- Preliminary steps include:

- Close all cab windows and doors.

- Set the air conditioning to maximum cooling and blower speed.

- Ensure manifold gauge readings are within the normal range relative to ambient temperature.

- Verify the evaporator discharge air temperature aligns with recommended settings for the current conditions.

- Check hoses and components on the high side for warm-hot temperature. If the receiver-drier outlet is cooler than the inlet, a restriction is indicated.

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.