Komatsu SK820-5N Skid-Steer Loader Service Manual

$33.50

This comprehensive Shop Manual is essential for maintaining and repairing your Komatsu SK820-5N Skid-Steer Loader. Spanning 365 pages, it covers every detail for serial numbers A40001 and up.

SKU: 769681

Categories: Komatsu, Skid-Steer

Comprehensive Shop Manual

Product Overview

This extensive shop manual is designed to enhance the quality of repairs by providing users with a thorough understanding of machinery components and the correct procedures for repairs and assessments. It aims to ensure technical accuracy and efficiency, primarily serving as a critical resource within service workshops.

Organized into distinct chapters dedicated to major component categories, this manual enables seamless navigation and focused learning.

Key Features

- General Information: Includes comprehensive details on machine dimensions, performance specifications, component weights, and charts for fuel, coolant, and lubricant specifications.

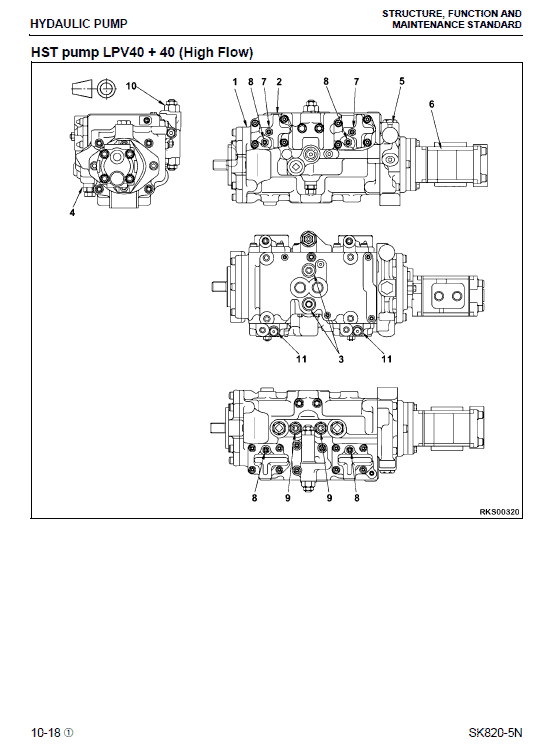

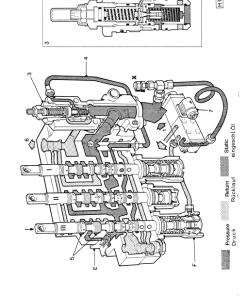

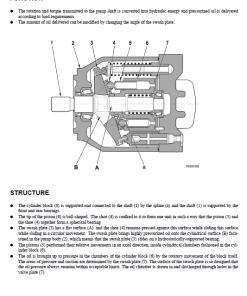

- Structure, Function, and Maintenance Standards: Offers detailed exploration of component structures and functions, supplemented by essential troubleshooting reference material and inspection judgement standards.

- Standard Value Tables: Provides critical standard values for new machinery and benchmarks for testing, adjusting, and troubleshooting.

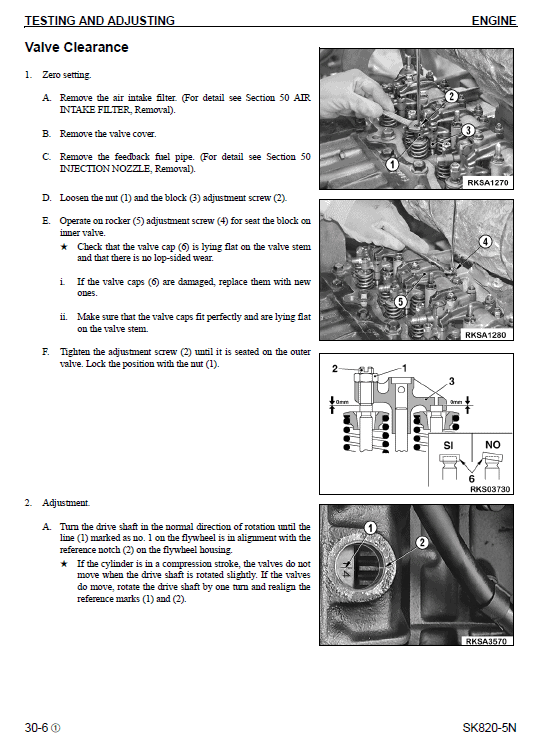

- Testing and Adjusting: Guides users through pre- and post-repair checks and adjustment protocols.

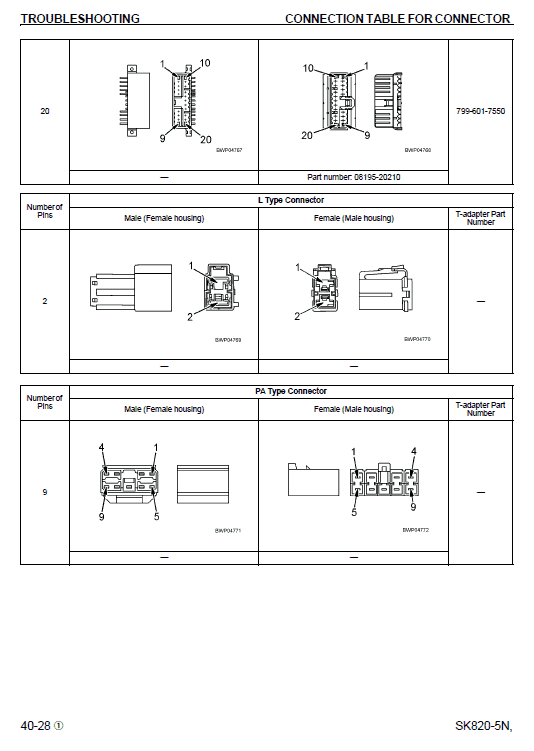

- Troubleshooting: Includes problem-to-cause correlation charts to aid in efficient diagnosis and resolution.

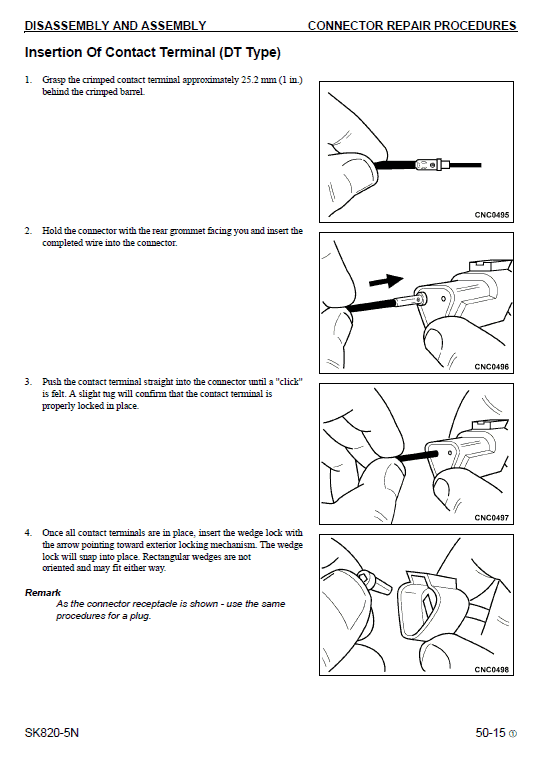

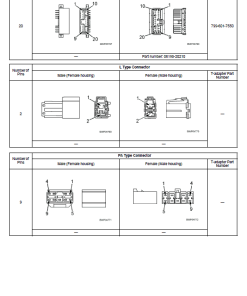

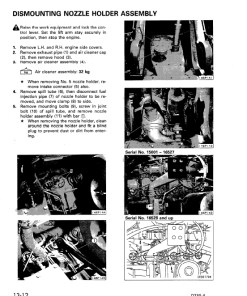

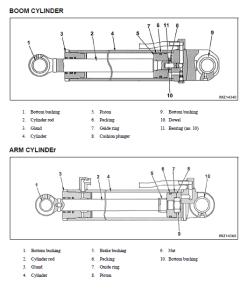

- Disassembly and Assembly: Outlines procedures for the orderly removal, installation, disassembly, and assembly of components, complete with precautionary measures.

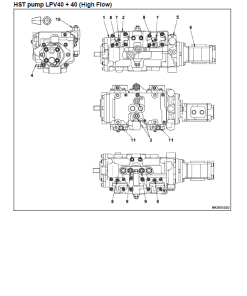

- Diagrams and Schematics: Features foldout drawings for an enhanced visual understanding of the machinery.

Benefits

- Improves repair quality through an in-depth understanding of mechanical systems.

- Facilitates accurate judgment and efficient repair processes in workshop settings.

- Supports troubleshooting and maintenance with detailed procedural guidelines.

Usage Recommendations

- Ensure thorough understanding of each manual section to fully leverage repair and maintenance protocols.

- Prior to troubleshooting, conduct initial checks including:

- Assessing oil levels.

- Inspecting for external oil leaks in piping or hydraulic systems.

- Verifying the travel and function of control levers and valve spools.

- Performing external checks on additional maintenance items as necessary.

- When confirming failures, accurately assess the extent of the issue to distinguish genuine mechanical failures from operational errors. Avoid exacerbating problems during diagnosis or by conducting invasive measurements.

Only logged in customers who have purchased this product may leave a review.

Related products

$34.00

$32.50

$34.50

$34.00

$34.00

Reviews

There are no reviews yet.