Table of Contents

- General

- Power Train

- Steering System

- Air System

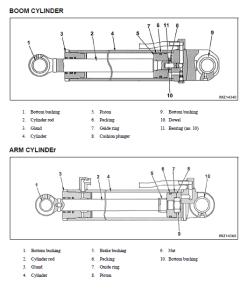

- Hydraulic System

- Work Equipment

- Others

Inspection of Steering Linkage

Ensure the safety and optimal performance of your machinery by regularly inspecting the steering linkage. Follow these detailed steps to conduct a thorough examination:

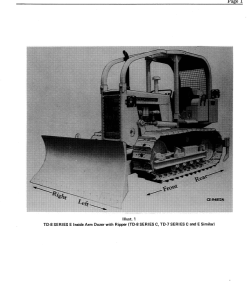

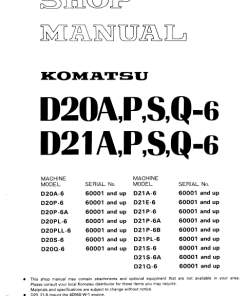

Product Overview

Our Steering Linkage Inspection Guide is designed to help you maintain the critical components of your vehicle’s steering system. Proper inspection enhances operational safety and performance.

Key Features

- Comprehensive inspection procedures.

- Guidelines for checking tire inflation and alignment.

- Instructions for verifying bolt and nut tightness.

- Clearance measurement instructions between frame stoppers.

Benefits

- Ensures vehicle safety and reliability.

- Enhances steering accuracy and stability.

- Prevents wear and tear of steering components.

- Helps maintain manufacturer specifications.

Usage Recommendations

- Ensure all four wheels have the same tire pressure. Refer to the operation and maintenance manual for the specific pressure values.

- Position the machine on a paved and level ground before starting the inspection.

- Start the engine, align the front and rear frames by adjusting the steering wheel, and then apply the safety bar and stop the engine. Ensure the parking brake is engaged.

- Check all linkage bolts and nuts for tightness and inspect the drag link ball joint for any deflection. Ensure the pitman arm is perpendicular to the ground.

- Start the engine, remove the safety bar, and turn the steering wheel until the pitman arm contacts the stopper. Measure the clearance between the front and rear frame stoppers; it should be 12.7 u00b1 6 mm.

Only logged in customers who have purchased this product may leave a review.

Related products

$34.00

$32.50

$34.00

$27.50

Reviews

There are no reviews yet.