Engine Maintenance and Blow-By Pressure Measurement Guide

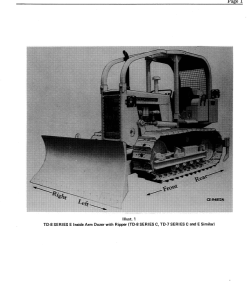

Product Overview

This manual provides detailed instructions on correctly measuring blow-by pressure, crucial for maintaining engine performance and assessing potential engine wear or failure. Understanding and adhering to these guidelines will ensure the longevity and efficiency of your engine.

Table of Contents

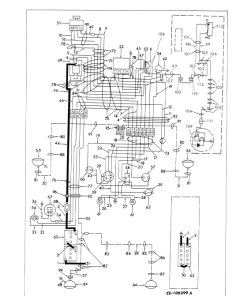

- Contents

- Engine

- Power Train

- Steering System

- Brake System

- Work Equipment System

- Electric and Electronic System

- Others

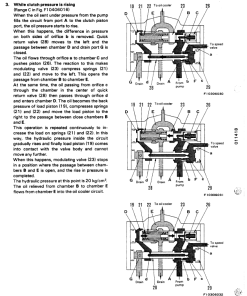

Measuring Blow-By Pressure

Standard Value: Maximum 50

Permissible Value: 100

Instructions:

- Ensure the engine is warmed up to operating temperature by running it until the coolant reaches this range.

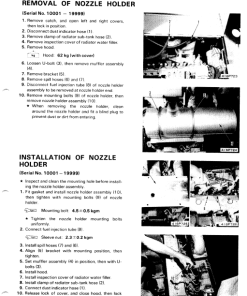

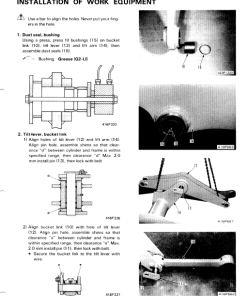

- Turn off the engine and proceed to remove the muffler, air suction hose, and head covers.

- Seal the three air vent tubes securely.

- Reattach the head covers, air suction hose, and muffler.

-

- Detach the engine oil filler cap and install the blow-by checker adapter in its place.

- Connect the adapter to tool A using a tube capable of measuring 0 – 1000 mm H2O.

- Operate the engine at high idle speed and record the blow-by pressure.

- Once completed, remove the plugs from the air vent tubes.

Notes:

- It is advisable to measure the blow-by pressure while the engine is delivering its rated horsepower.

- An approximate reading can be achieved by performing measurements with the machine stalled under load.

- If unable to measure while the engine is at full output, a high idle reading will yield approximately 80% of the true pressure under full horsepower.

- Be aware that engine conditions significantly impact blow-by pressure. If abnormal readings are observed, inspect for issues such as excessive oil consumption, smoke exhaust, or rapid deterioration of engine oil.

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.