Komatsu WA1200-3 Switching Pump Assembly Removal Guide

Product Overview

Efficiently manage the removal and installation of the switching pump assembly on your Komatsu WA1200-3 machine by following this detailed guide. This procedure ensures proper handling of components and prevents potential damage. Ensure you have all necessary replacement parts on hand, such as hoses and O-rings, as they need to be replaced during reinstallation.

Table of Contents

- 01 General Information

- 10 Structure and Function

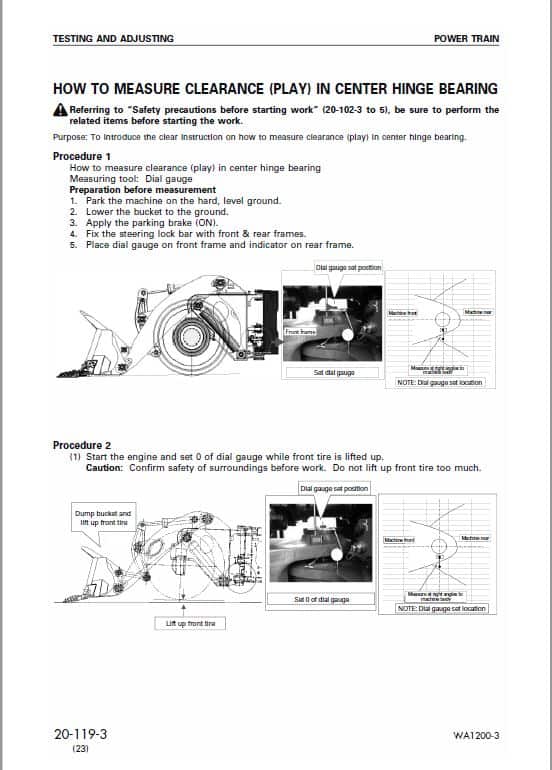

- 20 Testing and Adjusting

- 30 Disassembly and Assembly

- 40 Maintenance Standard

- 90 Others

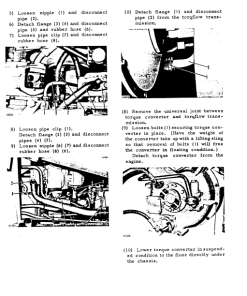

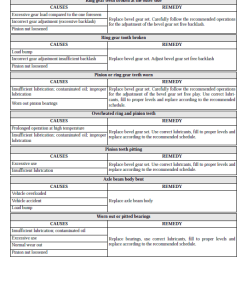

Removal Process

Before commencing with the removal of the switching pump assembly, perform the tasks outlined in “2. Preparatory work” and “3. Precautions during work” of “00-3 Safety Notice” to ensure safe and effective removal.

Step-by-Step Guide

- Drain the hydraulic oil. Volume: Approximately 1,125 liters.

- Open the upper step cover to access internal components.

- Disconnect hoses labeled (1) and (2).

- Proceed to detach hoses (3) and (4).

- Remove U-bolt (5) before disconnecting the suction tube (6).

- Disconnect hose labeled (7).

- Detach hoses (8) and (9).

- Sling the switching pump assembly (10) carefully, remove its mounting bolts, and lift it off.

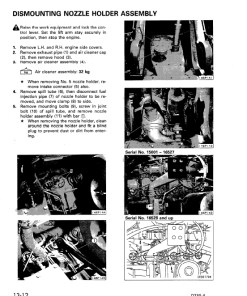

For reference, here is an image of the switching pump assembly.

Key Features

- Switching pump assembly weighing 190 kg.

- Comprehensive guide for safe disassembly.

- Requirements for replacement of consumable parts.

Benefits

- Ensures smooth removal and installation process.

- Minimizes downtime with detailed step-by-step instructions.

- Prevents potential damage to machinery with careful procedure.

Usage Recommendations

- Always replace consumable parts during the reinstallation process.

- Have all necessary tools and parts ready before starting the procedure.

- Strictly follow precautionary measures for safe handling.

Only logged in customers who have purchased this product may leave a review.

Related products

$32.50

$34.00

$27.50

$34.00

Reviews

There are no reviews yet.