Komatsu WA200-1 Maintenance Manual

Product Overview

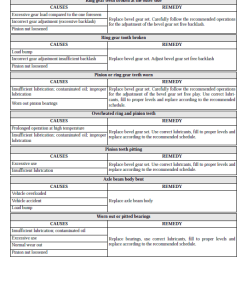

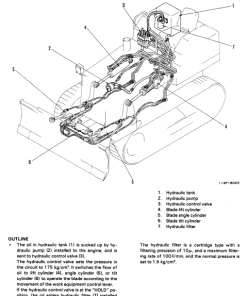

This comprehensive maintenance manual for the Komatsu WA200-1 provides detailed instructions for troubleshooting and servicing various components. It covers vital areas such as the engine, power train, steering systems, brakes, air systems, electronic and electrical systems, work equipment, and more. Ideal for maintenance professionals and DIY enthusiasts, this guide ensures your equipment remains in peak condition.

Key Features

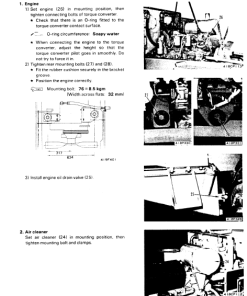

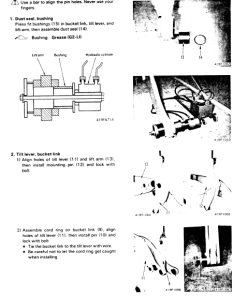

- Step-by-step instructions for adjusting fuel injection timing.

- Easy-to-follow diagrams and images for enhanced understanding.

- Covers a wide range of systems: from basic to advanced operations.

- Details on maintenance procedures and safety precautions.

Benefits

- Ensures optimal performance and longevity of your Komatsu WA200-1.

- Facilitates timely maintenance, reducing downtime.

- Empowers users with knowledge for self-service and maintenance.

- Increases safety by adhering to recommended procedures.

Usage Recommendations

- Always follow the step-by-step procedures for safety and accuracy.

- Use this manual as a reference during regular maintenance checks.

- Consult with a professional for complex repairs if necessary.

- Store in a dry, clean place to ensure the manual’s longevity.

Adjusting Fuel Injection Timing – Step-by-step Guide

- Turn the crankshaft back by 30-40u00b0 from the top dead center.

- Rotate the crankshaft until the “I.J.” line on the crankshaft pulley aligns correctly with the pointer.

- Loosen nut (7) in the oblong hole on the mounting flange of the fuel injection pump.

- Operate the priming pump (8) and rotate the coupling on the injection pump side slightly, then stop where fuel begins to flow from the delivery valve holder.

- Tighten nut (7) in the oblong hole of the mounting flange of the fuel injection pump. After tightening, ensure that the fuel flow from the delivery valve holder stops when the pointer aligns with the line on the crankshaft pulley.

- Remove the delivery valve holder (2), assemble the delivery valve (3) and spring (4), then reinstall the delivery valve holder (2). Delivery holder torque specification: 3.3 u00b1 0.2 kgm.

- Connect the fuel injection pipe (1). Sleeve nut torque specification: 2.4 u00b1 0.1 kgm.

For more details and a visual guide, please view the illustrative image.

Only logged in customers who have purchased this product may leave a review.

Related products

$34.00

$34.50

$34.00

$33.50

Reviews

There are no reviews yet.