Inspection and Maintenance Manual

Table of Contents

- Contents

- General Information

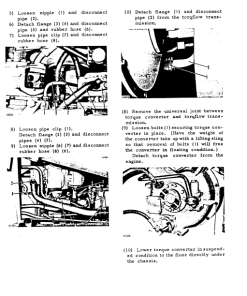

- Engine

- Power Train

- Steering System

- Brake System

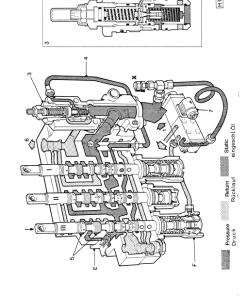

- Work Equipment System

- Electric and Electronic System

- Additional Components

Inspection Protocol for Part Assessment

Ensuring each mechanical component functions flawlessly is crucial. Our rigorous inspection protocol is designed to detect potential issues early. Below are the guidelines:

Visual Inspection Guidelines

- Before beginning, ensure all parts are thoroughly cleaned.

- Inspect for visible damages such as cracks, pitting, corrosion, scoring, and ridging.

- Identifying the source of failures can guide preventive actions and provide practical advice for customers to mitigate future issues.

Note: Visual checks may miss subtle or hidden damages; additional testing might be necessary.

Advanced Inspection Methods

- Water-pressure or air-pressure tests can be employed for detecting leaks or weaknesses.

- Cold checks or magnetic damage tests are recommended for thorough analysis.

Specific Defects and Solutions

Crack Detection and Management

- If cracks are visible, consider replacing the part.

- Replace parts if crack length or depth surpasses one-third of the part’s thickness.

- Internal cracks warrant component replacement.

Pitting Examination and Remedies

Pitting from Cavitation

- Cavitation often coexists with chemical corrosion. Post rust or scale removal, evaluate pitting depth meticulously.

- If pitting is irreparable within tolerable limits, part replacement is necessary.

- For minor pitting, resurface after rust and scale removal.

Pitting from Surface Wear

- Replace ball bearings if pitting is present.

- Parts with over one-third pitted contact surface should be replaced.

- Minor pitting warrants resurfacing of the component.

Conclusion

Proper maintenance and timely inspections are key to long-term functionality and safety of mechanical systems. Adhering to these guidelines will ensure maximum efficiency and longevity.

Only logged in customers who have purchased this product may leave a review.

Related products

$33.50

$27.50

Reviews

There are no reviews yet.