Transmission Control Valve Manual Overview

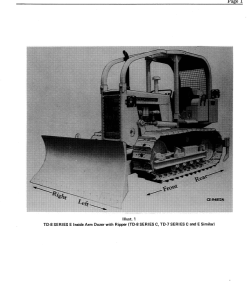

Product Overview

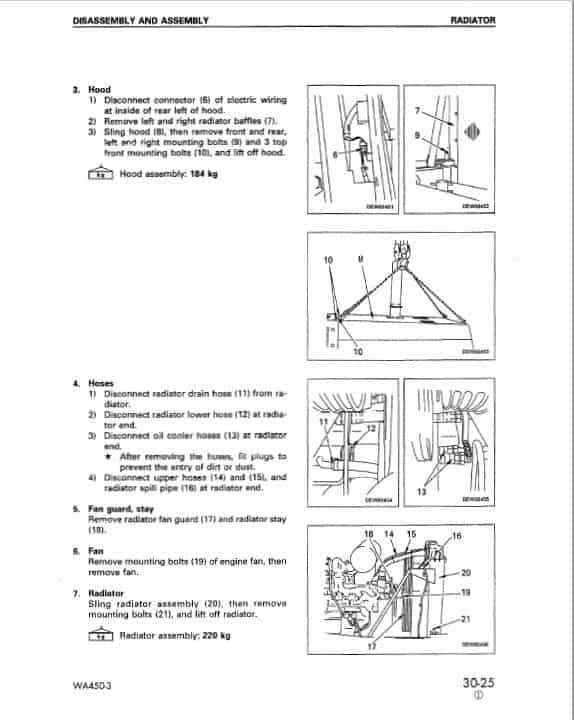

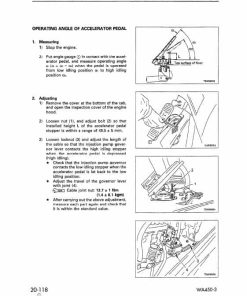

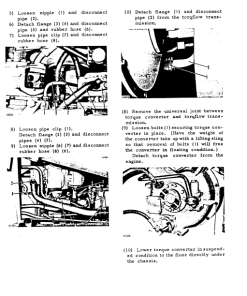

This comprehensive manual provides detailed insights into the transmission control valve’s operation within heavy machinery systems, using oil flow regulation for optimal performance. It includes sections on general information, structure and function, testing and adjustments, disassembly and assembly, and maintenance standards.

Key Features

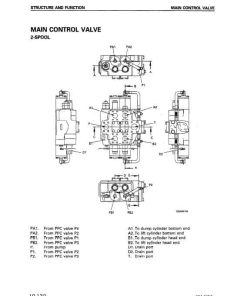

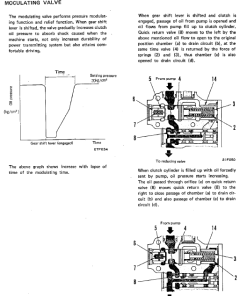

- Flow Management: Oil from the pump is directed through a flow valve and an oil filter before entering the transmission valve, where it is split into the pilot circuit and clutch actuation circuit.

- Pressure Regulation: The priority valve controls pump delivery pressure, ensuring adequate pilot and oil pressure for releasing the parking brake.

- Electronic Control Modulation: An electronic control modulation valve regulates oil pressure to smoothly actuate the clutch by sensing machine and engine speeds.

- Automatic Shift Adjustment: The transmission controller interacts with the proportional solenoid valve to seamlessly change gear speeds and engage the clutch.

- Solenoid Valve Functionality: Control of directional and range spools through solenoid valve activation ensures the correct speed range for the clutch.

Benefits

- Enhanced Performance: Minimizes shock during gear speed changes and ensures smooth clutch engagement for better machine operation.

- Consistent Clutch Pressure: Maintains set clutch pressure when the machine is in motion, promoting reliability and equipment longevity.

- Ease of Operation: Streamlined operation through precise electronic pressure and flow control, reducing manual intervention.

Usage Recommendations

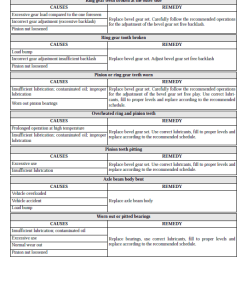

- Refer to this manual for guidance on diagnosing and resolving transmission control valve issues.

- Implement periodic maintenance checks to ensure the system’s integrity and performance as specified in the maintenance standard section.

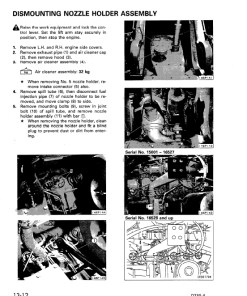

- Utilize the manual’s disassembly and assembly techniques for efficient parts replacement and troubleshooting.

Only logged in customers who have purchased this product may leave a review.

Related products

$34.00

$27.50

$33.50

$34.00

$32.50

Reviews

There are no reviews yet.