Emergency Steering System Overview

Product Overview

The Emergency Steering System is an advanced feature designed to enhance the safety and reliability of your machinery by automatically verifying the system’s operability. This self-check occurs within a few seconds after activating the machine, ensuring that the steering system is ready for use under all emergency conditions.

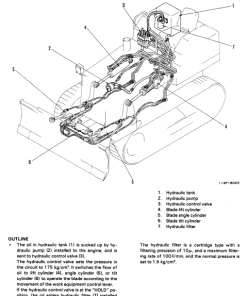

Table of Contents

- Index and Foreword

- Specification

- Structure, Functions, and Maintenance Standards

- Standard Value Table

- Testing and Adjusting

- Troubleshooting

- Disassembly and Assembly

- Diagrams and Drawings

Key Features

- Automatic self-check of operability shortly after activation.

- Integration with machine monitor for seamless operation.

- Capable of interfacing with the transmission controller to ensure system readiness.

Benefits

- Enhanced safety by ensuring the steering system is operational under emergency conditions.

- Reliable performance through periodic self-assessment of key functions.

- Reduced risk of machinery downtime with early error detection.

Usage Recommendations

- Ensure the machine is regularly serviced to maintain the emergency steering system’s efficiency.

- Familiarize operators with the conditions under which the self-check may not be performed, such as:

- When the starting switch is in the “START” position and the motor is running.

- When the engine is already operational at speeds over 500 RPM.

- During active steering oil pressure sensing.

- When the automatic preheater is active.

- If errors are detected during the self-check process.

- If engine run time since the last self-check is less than 10 seconds.

- Monitor for any error messages generated by the system, indicating issues with the self-check process.

Only logged in customers who have purchased this product may leave a review.

Related products

$27.50

$34.50

$34.00

Reviews

There are no reviews yet.