Kubota U17-3a Excavator Workshop Service Manual

Product Overview

The Kubota U17-3a Excavator Workshop Service Manual is an essential guide for maintaining and servicing the Kubota U17-3a Excavator. This manual provides detailed instructions and in-depth information on machine maintenance and repair, ensuring optimal performance. Available in PDF format, it is easily accessible and portable for your convenience.

Publication: 97899-61952

Format: PDF

Language: English

Pages Included: Workshop Manual – 722 Pages, Operators Manual – 97 Pages

Key Features

- Comprehensive maintenance and servicing guidelines for the Kubota U17-3a Excavator.

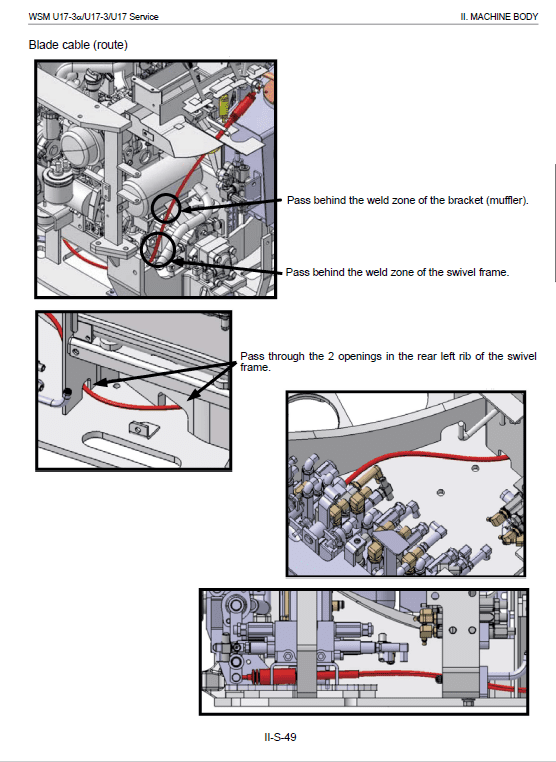

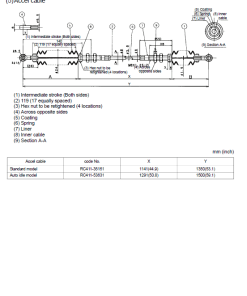

- Detailed breakdown of the excavator’s components, including the engine, hydraulic system, and electrical system.

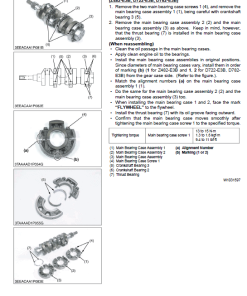

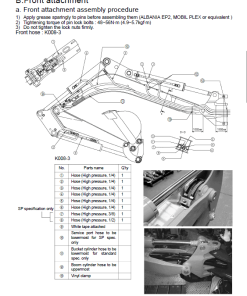

- Clear and precise assembly and disassembly instructions.

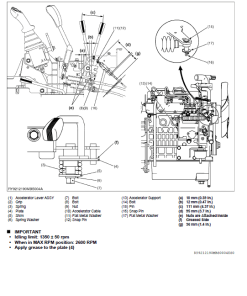

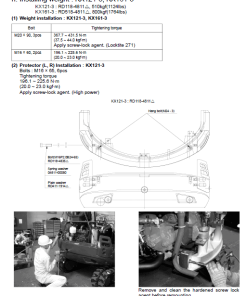

- Helpful diagrams and illustrations to assist in understanding the machine’s structure.

Benefits

- Ensures the excavator operates at peak efficiency and extends its lifespan.

- Empowers users to perform routine maintenance, reducing downtime and repair costs.

- Enhances safety by providing detailed operational procedures and warning notices.

Usage Recommendations

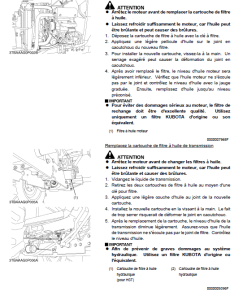

- Thoroughly read and familiarize yourself with the manual before performing any maintenance or repairs.

- Conduct regular inspections as outlined in the manual to identify any potential issues early.

- Follow the specified working procedures to safely disassemble and reassemble the machine.

- After reassembling, check for unusual noises and vibrations, ensure safety decals and wire harness clamps are correctly positioned, and confirm the hydraulic oil level.

Table of Contents Highlights

The manual is structured into comprehensive sections including:

- I. General

- II. Machine Body

- Mechanism Section

- Service Section

- III. Engine

- Mechanism Section

- Service Section

- IV. Hydraulic System

- Mechanism Section

- Service Section

- V. Electrical System

- Mechanism Section

- Service Section

Important Inspection Items After Reassembly

- Check the excavator for unusual noises and vibrations during operation.

- Ensure that all safety decals and wire harness clamps are in the correct positions.

- With the machine in the specified posture, verify that the hydraulic oil level is correct. Follow the steps outlined in the Operators Manual for this procedure.

Kubota U17-3a Excavator Alternator Unit Test

Prior to conducting an alternator test:

- Inspect battery terminals, circuit connections, fan belt tension, charging indicator lamp, and fuses.

- Ensure no abnormal noises are coming from the alternator and prepare a fully charged battery.

Testing Procedure:

- Start the engine and remain at a safe distance from moving parts.

- Measure the voltage across the battery terminals. A voltage range of 13.8 V to 14.8 V indicates normal alternator function.

- If voltage readings fall outside this range, disassemble the alternator to inspect and diagnose component failures.

Only logged in customers who have purchased this product may leave a review.

Related products

$33.00

$29.50

$30.00

$32.00

$33.00

$34.50

$35.00

$34.00

Reviews

There are no reviews yet.