Liebherr LH150C, LH150M Tier 4F Hydraulic Excavator Service Manual

$34.00

The Liebherr LH150C (Type 1231) and Liebherr LH150M (Type 1230) Tier 4F Excavators are expertly covered in these comprehensive manuals. Suitable for models with serial numbers 71201 and up for the LH150C, and 86329 and up for the LH150M.

Language: English

Publication: 11826709

Format: PDF

Publication Date: January 2018

Liebherr LH150C, LH150M Excavator Service Manual – 954 Pages

Operator’s Manual – 284 Pages

Liebherr LH150C, LH150M Tier 4F Hydraulic Excavator Service Manual

Product Overview

The Liebherr LH150C and LH150M Tier 4F Hydraulic Excavator Service Manual is an essential resource for anyone involved in the operation, servicing, or maintenance of these advanced machines. This manual covers models LH 150 C (4f) 71201 and up (Type 1231) and LH 150 M (4f) 86329 and up (Type 1230). Written in English and published in January 2018, the manual is available in PDF format and is a comprehensive guide comprising 954 pages for service details and an additional 284 pages for the operator’s manual.

Table of Contents

- Introduction

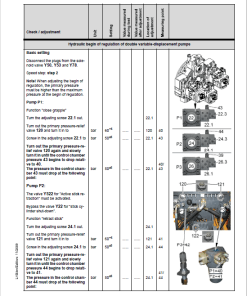

- Technical Data

- Maintenance

- Drive Group

- Cooling System

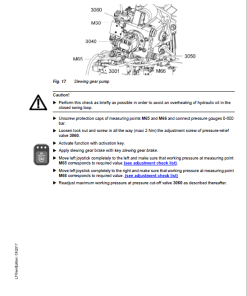

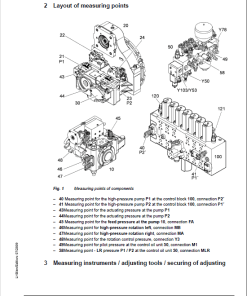

- Working Hydraulics

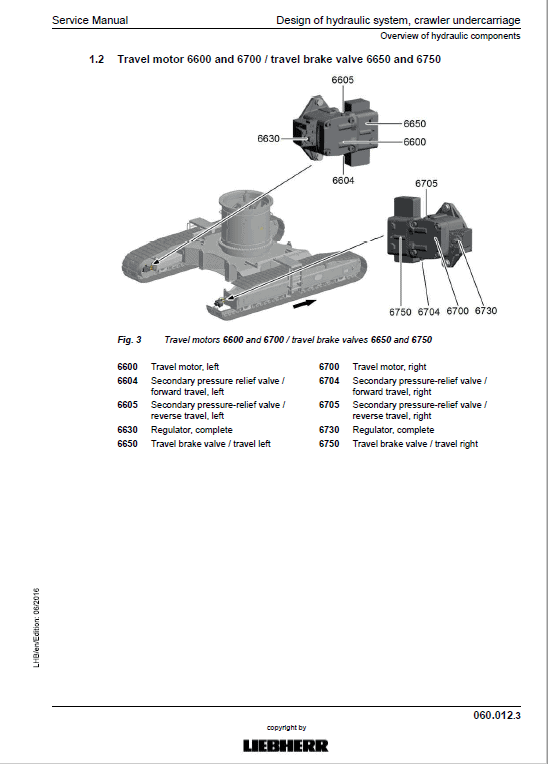

- Hydraulic Components

- Steering System

- Brake System

- Electrical System

- Transmission / Travel Gearbox

- Axles / Drive

- Steel Components – Basic Machine

- Working Attachment

- Operatoru2019s Cab, Heating and Air Conditioning

- Lubrication System

- Slewing Gearbox and Slewing Ring

- Equipment / Options

- Diagnosis

Key Features

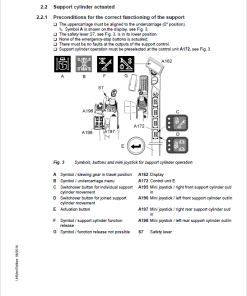

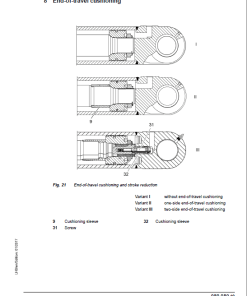

- Comprehensive technical data, design, and functional descriptions.

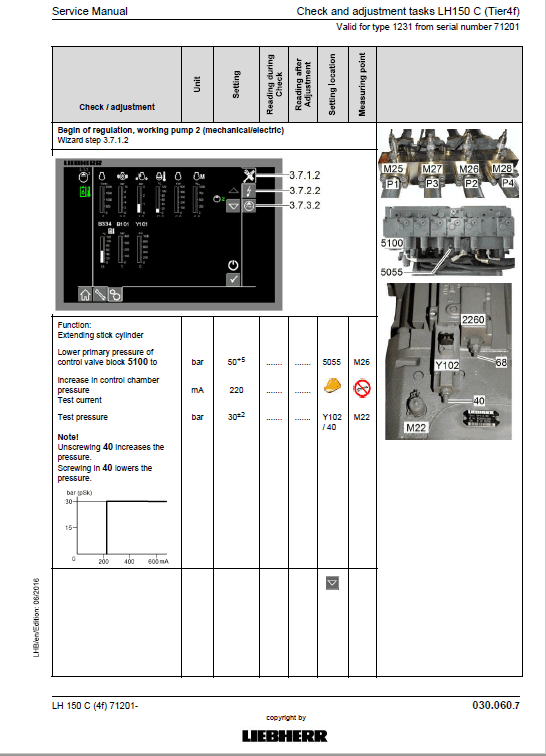

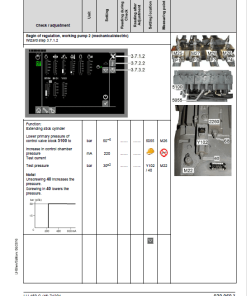

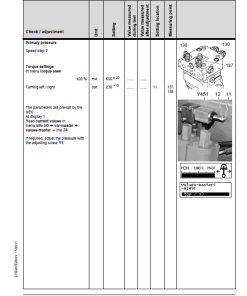

- Detailed instructions for machine operations and settings adjustments.

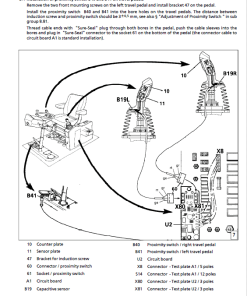

- Includes numerous drawings, schematics, and detailed views of components.

- Supports customer service operations though not a substitute for technical training.

Benefits

- Enhances understanding of Liebherr hydraulic excavators.

- Facilitates proper maintenance and servicing for optimal machine performance.

- Serves as a valuable training resource for operators and technicians.

Usage Recommendations

- Use this manual in conjunction with Liebherr operator training courses for best results.

- Refer to separate documentation for operating instructions and spare parts information.

- Keep the manual accessible for quick reference during service and troubleshooting.

Accumulator Information

The manual provides an extract on accumulators, noting that liquids, being incompressible, are unable to store pressure energy directly. Instead, nitrogen gas is used in the accumulators for these machines. The accumulator serves to store pressure oil for systems like the servo control, brake, and oscillating axle support. It consists of a hydraulic section and a gas section within a metal pressure vessel, with different designs, such as diaphragm, bladder, and piston accumulators.

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.