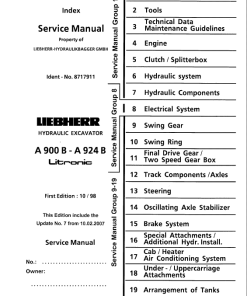

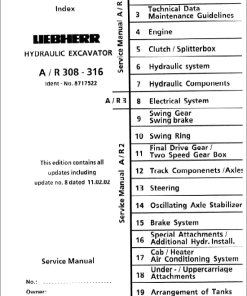

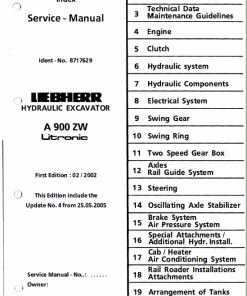

Liebherr R914 Compact, R920 Tier 4F Compact Excavator Service Manual

$36.00

Models Covered: R 914 Compact (Type 1511, Serial 89078 and up) and R 920 Compact (Type 1705, Serial 43057 and up)

Language: English

Publication Number: 12214599

Format: PDF

This comprehensive service manual encompasses crucial guidelines for the Liebherr R914 and R920 Compact Excavators. With 1,522 pages, it provides in-depth service instructions essential for maintaining these machines. Additionally, the package includes a 330-page operator’s manual for effective machine operation.

Liebherr R914 Compact, R920 Tier 4F Compact Excavator Service Manual

Product Overview

The Liebherr R914 Compact, R920 Tier 4F Excavator Service Manual is an essential guide for maintaining and servicing your Liebherr excavators. Specifically designed for the R914 Compact (89078 and up, Type 1511) and R920 Compact (43057 and up, Type 1705) models, this manual is a comprehensive resource available in English and provided in PDF format. It consists of 1522 pages of detailed service instructions, complemented by a 330-page operator’s manual.

Key Features

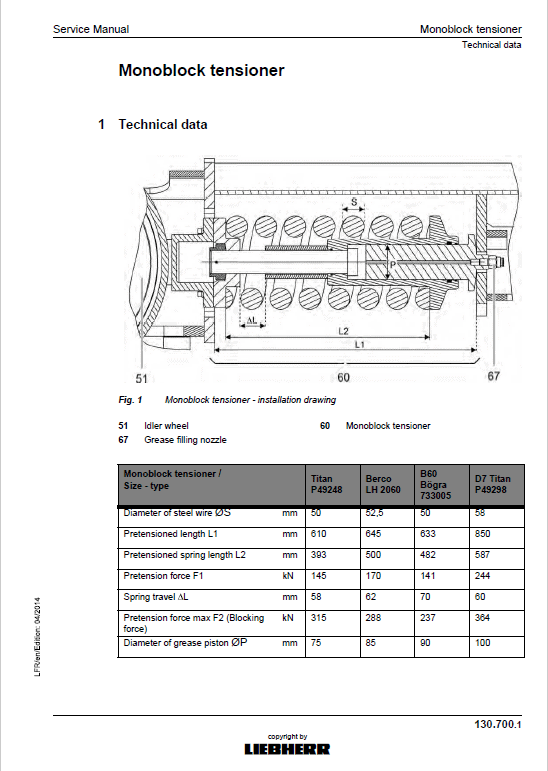

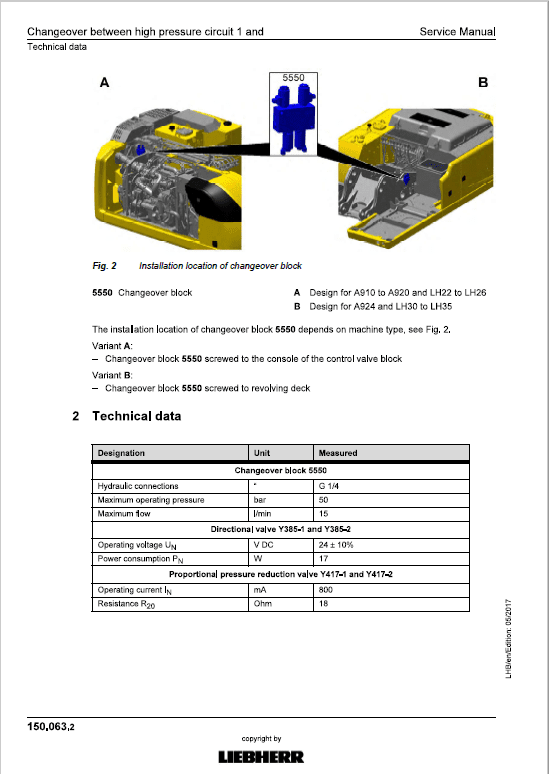

- Detailed Technical Data: Provides extensive specifications and operational data.

- Comprehensive Maintenance Guidelines: Offers step-by-step maintenance instructions to ensure optimal performance.

- Extensive Diagram Library: Includes a wide array of diagrams, schematics, and detailed unit and assembly views.

- 1500+ Pages of Content: Covers every aspect of service and repair for these models.

Benefits

- Enhanced Equipment Longevity: Regular maintenance and correct servicing contribute to extended machine life.

- Efficient Troubleshooting: In-depth diagnostic insights assist in swiftly resolving technical issues.

- Optimal Performance: Ensures that your excavators operate at peak efficiency.

- Safety Assurance: Adherence to service guidelines reduces the risk of machinery failure and accidents.

Usage Recommendations

- Refer to the Manual Regularly: Consult for scheduled maintenance and servicing requirements to keep your equipment in top condition.

- Diagnostic and Troubleshooting: Use the extensive diagnostic guide to identify and solve issues quickly.

- Understand System Mechanics: Gain a thorough understanding of operating principles and system interdependencies.

- Measure Performance: Utilize described methodologies to assess component efficacy, such as the leak oil check for control blocks.

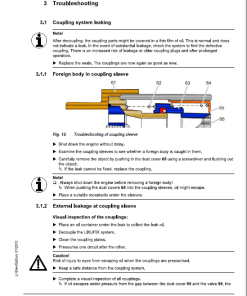

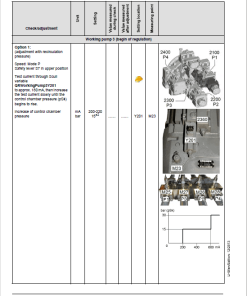

Detailed Guide to Checking Leak Oil

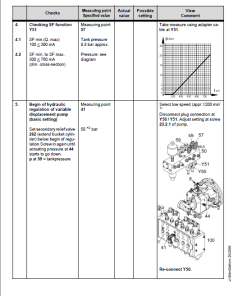

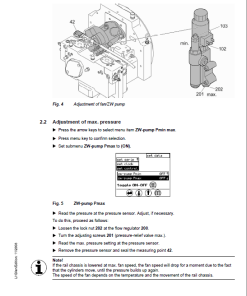

The manual also includes instructions for conducting specific checks, such as measuring leak oil at control blocks. This process involves measuring the retracting and extending speeds of the pressurized hydraulic cylinder with the control spool in a neutral position. The procedure requires measuring the leak oil volume at a load pressure of 150 bar and a temperature of 50u00b0C. Prior to this measurement, inspect the secondary valves and the operating cylinder to ensure accurate readings pertaining solely to the control spool’s leakage.

For detailed setup, a pressure sensor should be connected at the respective pressure line between the operating cylinder and the control block, using appropriate measuring equipment as needed.

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.