-

×

Bobcat 2200, 2200s and 2300 Utility Vehicle Service Manual

$32.00

Bobcat 2200, 2200s and 2300 Utility Vehicle Service Manual

$32.00 -

×

JCB 430ZX Wheeled Loader Shovel Service Manual

$34.00

JCB 430ZX Wheeled Loader Shovel Service Manual

$34.00 -

×

John Deere 862B Series II Scraper Repair Technical Manual (S.N after 818323)

$39.00

John Deere 862B Series II Scraper Repair Technical Manual (S.N after 818323)

$39.00 -

×

John Deere 862 Scraper Repair Technical Manual (TM1212)

$38.00

John Deere 862 Scraper Repair Technical Manual (TM1212)

$38.00 -

×

John Deere 710J Backhoe Loader Technical Manual (S.N before - 159769 & 161144 - 172184 )

$56.00

John Deere 710J Backhoe Loader Technical Manual (S.N before - 159769 & 161144 - 172184 )

$56.00 -

×

Caterpillar CAT 160H Motor Grader Service Repair Manual (9JM00001 and up)

$75.00

Caterpillar CAT 160H Motor Grader Service Repair Manual (9JM00001 and up)

$75.00 -

×

Caterpillar CAT 140B Motor Grader Service Repair Manual (33C00001 and up)

$80.00

Caterpillar CAT 140B Motor Grader Service Repair Manual (33C00001 and up)

$80.00 -

×

John Deere 762B Series II Scraper Repair Technical Manual (S.N after 818909)

$39.00

John Deere 762B Series II Scraper Repair Technical Manual (S.N after 818909)

$39.00 -

×

Bobcat TR38160, TR38160 EVO versaHANDLER Telescopic Service Repair Manual

$36.00

Bobcat TR38160, TR38160 EVO versaHANDLER Telescopic Service Repair Manual

$36.00 -

×

Caterpillar CAT 12M Motor Grader Service Repair Manual (R9B00001 and up)

$70.00

Caterpillar CAT 12M Motor Grader Service Repair Manual (R9B00001 and up)

$70.00 -

×

Bobcat S630 Skid-Steer Loader Service Manual

$34.00

Bobcat S630 Skid-Steer Loader Service Manual

$34.00 -

×

JCB 3C, 3CX, 4CX Backhoe Loader Service Repair Manual (960001 to 1625999)

$44.00

JCB 3C, 3CX, 4CX Backhoe Loader Service Repair Manual (960001 to 1625999)

$44.00 -

×

John Deere 410L Backhoe Loader Technical Manual (S.N C390996 & D390996 - )

$56.00

John Deere 410L Backhoe Loader Technical Manual (S.N C390996 & D390996 - )

$56.00 -

×

Caterpillar CAT 140K 2 Motor Grader Service Repair Manual (SZW00001 and up)

$70.00

Caterpillar CAT 140K 2 Motor Grader Service Repair Manual (SZW00001 and up)

$70.00 -

×

Caterpillar CAT 160M SERIES 2 Motor Grader Service Repair Manual (R9T00001 and up)

$70.00

Caterpillar CAT 160M SERIES 2 Motor Grader Service Repair Manual (R9T00001 and up)

$70.00 -

×

Caterpillar CAT CS-663E, CP-663E Vibratory Compactor Service Repair Manual (ASF00001 and up)

$50.00

Caterpillar CAT CS-663E, CP-663E Vibratory Compactor Service Repair Manual (ASF00001 and up)

$50.00 -

×

Caterpillar CAT 12H ES Motor Grader Service Repair Manual (2GS00001 and up)

$70.00

Caterpillar CAT 12H ES Motor Grader Service Repair Manual (2GS00001 and up)

$70.00 -

×

Caterpillar CAT 160M 2 Motor Grader Service Repair Manual (M9E00001 and up)

$70.00

Caterpillar CAT 160M 2 Motor Grader Service Repair Manual (M9E00001 and up)

$70.00 -

×

Caterpillar CAT 120G Motor Grader Service Repair Manual (82V00001 till 00667)

$80.00

Caterpillar CAT 120G Motor Grader Service Repair Manual (82V00001 till 00667)

$80.00 -

×

Caterpillar CAT 140G Motor Grader Service Repair Manual (13W00425 till 00740)

$70.00

Caterpillar CAT 140G Motor Grader Service Repair Manual (13W00425 till 00740)

$70.00 -

×

Caterpillar CAT 12H NA Motor Grader Service Repair Manual (4XM00001 and up)

$70.00

Caterpillar CAT 12H NA Motor Grader Service Repair Manual (4XM00001 and up)

$70.00 -

×

Caterpillar CAT 120G Motor Grader Service Repair Manual (82V00001 and up)

$80.00

Caterpillar CAT 120G Motor Grader Service Repair Manual (82V00001 and up)

$80.00 -

×

Caterpillar CAT 135H NA Motor Grader Service Repair Manual (3YK00001 and up)

$70.00

Caterpillar CAT 135H NA Motor Grader Service Repair Manual (3YK00001 and up)

$70.00 -

×

Caterpillar CAT 140G Motor Grader Service Repair Manual (72V00001 till 00822)

$80.00

Caterpillar CAT 140G Motor Grader Service Repair Manual (72V00001 till 00822)

$80.00 -

×

Caterpillar CAT 140 Motor Grader Service Repair Manual (N9400001 and up)

$80.00

Caterpillar CAT 140 Motor Grader Service Repair Manual (N9400001 and up)

$80.00 -

×

Bobcat TL38.70, TL38.70X versaHANDLER Telescopic Service Repair Manual

$38.00

Bobcat TL38.70, TL38.70X versaHANDLER Telescopic Service Repair Manual

$38.00 -

×

Caterpillar CAT 160 Motor Grader Service Repair Manual (B5700001 and up)

$80.00

Caterpillar CAT 160 Motor Grader Service Repair Manual (B5700001 and up)

$80.00 -

×

JCB 403 Wheeled Loader Service Manual

$33.00

JCB 403 Wheeled Loader Service Manual

$33.00 -

×

John Deere XUV 850D M-Gator Utility Vehicle Technical Manual (TM1737)

$39.00

John Deere XUV 850D M-Gator Utility Vehicle Technical Manual (TM1737)

$39.00 -

×

John Deere 410E Backhoe Loader Repair Technical Manual

$52.00

John Deere 410E Backhoe Loader Repair Technical Manual

$52.00 -

×

Caterpillar CAT 140H NA Motor Grader Service Repair Manual (2ZK00001 and up)

$70.00

Caterpillar CAT 140H NA Motor Grader Service Repair Manual (2ZK00001 and up)

$70.00 -

×

Caterpillar CAT 160M3 AWD Motor Grader Service Repair Manual (N9K00001 and up)

$70.00

Caterpillar CAT 160M3 AWD Motor Grader Service Repair Manual (N9K00001 and up)

$70.00 -

×

John Deere 315SJ Backhoe Loader Manual (S.N after BE315SJ300869 & T0315SJ178876 - )

$54.00

John Deere 315SJ Backhoe Loader Manual (S.N after BE315SJ300869 & T0315SJ178876 - )

$54.00 -

×

Caterpillar CAT 140 Motor Grader Service Repair Manual (B5400001 and up)

$80.00

Caterpillar CAT 140 Motor Grader Service Repair Manual (B5400001 and up)

$80.00 -

×

John Deere 315SK Backhoe Loader Repair Technical Manual (S.N after C229820 & D219607 - )

$56.00

John Deere 315SK Backhoe Loader Repair Technical Manual (S.N after C229820 & D219607 - )

$56.00 -

×

Caterpillar CAT 120H Motor Grader Service Repair Manual (CAF00001 and up)

$80.00

Caterpillar CAT 120H Motor Grader Service Repair Manual (CAF00001 and up)

$80.00 -

×

Caterpillar CAT 150 Motor Grader Service Repair Manual (ENJ00001 and up)

$80.00

Caterpillar CAT 150 Motor Grader Service Repair Manual (ENJ00001 and up)

$80.00 -

×

Caterpillar CAT 16 Motor Grader Service Repair Manual (EN500001 and up)

$80.00

Caterpillar CAT 16 Motor Grader Service Repair Manual (EN500001 and up)

$80.00 -

×

Caterpillar CAT 160M Motor Grader Service Repair Manual (B9T00001 and up)

$70.00

Caterpillar CAT 160M Motor Grader Service Repair Manual (B9T00001 and up)

$70.00 -

×

Caterpillar CAT 120 Motor Grader Service Repair Manual (Y9D00001 and up)

$80.00

Caterpillar CAT 120 Motor Grader Service Repair Manual (Y9D00001 and up)

$80.00 -

×

Caterpillar CAT 120 Motor Grader Service Repair Manual (10R00001 and up)

$80.00

Caterpillar CAT 120 Motor Grader Service Repair Manual (10R00001 and up)

$80.00 -

×

John Deere 500C Backhoe Loader Repair Technical Manual (TM1038)

$38.00

John Deere 500C Backhoe Loader Repair Technical Manual (TM1038)

$38.00 -

×

Bobcat T36.120SL, T36.120SLRB versaHANDLER Telescopic Service Repair Manual

$38.00

Bobcat T36.120SL, T36.120SLRB versaHANDLER Telescopic Service Repair Manual

$38.00 -

×

Caterpillar CAT 130G Motor Grader Service Repair Manual (7GB00001 and up)

$80.00

Caterpillar CAT 130G Motor Grader Service Repair Manual (7GB00001 and up)

$80.00 -

×

Caterpillar CAT 150 Motor Grader Service Repair Manual (B5500001 and up)

$80.00

Caterpillar CAT 150 Motor Grader Service Repair Manual (B5500001 and up)

$80.00 -

×

Caterpillar CAT 140 GC Motor Grader Service Repair Manual (W9300001 and up)

$80.00

Caterpillar CAT 140 GC Motor Grader Service Repair Manual (W9300001 and up)

$80.00 -

×

Caterpillar CAT 140H Motor Grader Service Repair Manual (9TN00001 and up)

$70.00

Caterpillar CAT 140H Motor Grader Service Repair Manual (9TN00001 and up)

$70.00 -

×

John Deere 710L Backhoe Loader Repair Technical Manual (S.N after F294268 - F390995)

$60.00

John Deere 710L Backhoe Loader Repair Technical Manual (S.N after F294268 - F390995)

$60.00 -

×

Caterpillar CAT 14 Motor Grader Service Repair Manual (NN400001 and up)

$80.00

Caterpillar CAT 14 Motor Grader Service Repair Manual (NN400001 and up)

$80.00 -

×

Caterpillar CAT 120G Motor Grader Service Repair Manual (1LK00001 and up)

$80.00

Caterpillar CAT 120G Motor Grader Service Repair Manual (1LK00001 and up)

$80.00 -

×

Caterpillar CAT 140 Motor Grader Service Repair Manual (ENF00001 and up)

$80.00

Caterpillar CAT 140 Motor Grader Service Repair Manual (ENF00001 and up)

$80.00 -

×

Caterpillar CAT 120G Motor Grader Service Repair Manual (11W01019 till 11W01250)

$80.00

Caterpillar CAT 120G Motor Grader Service Repair Manual (11W01019 till 11W01250)

$80.00 -

×

Caterpillar CAT 140G Motor Grader Service Repair Manual (13W00741 till 00992)

$70.00

Caterpillar CAT 140G Motor Grader Service Repair Manual (13W00741 till 00992)

$70.00 -

×

Caterpillar CAT 143H Motor Grader Service Repair Manual (APN00001 and up)

$80.00

Caterpillar CAT 143H Motor Grader Service Repair Manual (APN00001 and up)

$80.00 -

×

Caterpillar CAT 140B Motor Grader Service Repair Manual (61S00001 and up)

$80.00

Caterpillar CAT 140B Motor Grader Service Repair Manual (61S00001 and up)

$80.00 -

×

JCB Groundhog 4x4 Utility Vehicle Service Manual

$31.00

JCB Groundhog 4x4 Utility Vehicle Service Manual

$31.00 -

×

John Deere 762A Scraper Repair Technical Manual (TM1225)

$38.00

John Deere 762A Scraper Repair Technical Manual (TM1225)

$38.00 -

×

JCB Vibromax 355, 365, 455, 465 Tandum Roller Service Manual

$26.70

JCB Vibromax 355, 365, 455, 465 Tandum Roller Service Manual

$26.70 -

×

Caterpillar CAT 120H Motor Grader Service Repair Manual (ALZ00001 and up)

$70.00

Caterpillar CAT 120H Motor Grader Service Repair Manual (ALZ00001 and up)

$70.00 -

×

JCB Vibromax VM106 Single Drum Roller Service Manual

$26.00

JCB Vibromax VM106 Single Drum Roller Service Manual

$26.00 -

×

Caterpillar CAT 120G Motor Grader Service Repair Manual (82V00668 and up)

$80.00

Caterpillar CAT 120G Motor Grader Service Repair Manual (82V00668 and up)

$80.00 -

×

Caterpillar CAT 150 Motor Grader Service Repair Manual (B5600001 and up)

$80.00

Caterpillar CAT 150 Motor Grader Service Repair Manual (B5600001 and up)

$80.00 -

×

John Deere 710J Backhoe Loader Technical Manual (S.N 159770 - 161143 and after 172185 - )

$54.00

John Deere 710J Backhoe Loader Technical Manual (S.N 159770 - 161143 and after 172185 - )

$54.00 -

×

Caterpillar CAT 12G Motor Grader Service Repair Manual (61M02629 till 07710)

$70.00

Caterpillar CAT 12G Motor Grader Service Repair Manual (61M02629 till 07710)

$70.00 -

×

Caterpillar CAT 160 Motor Grader Service Repair Manual (B5900001 and up)

$80.00

Caterpillar CAT 160 Motor Grader Service Repair Manual (B5900001 and up)

$80.00 -

×

Caterpillar CAT 140M Motor Grader Service Repair Manual (B9D00001 and up)

$70.00

Caterpillar CAT 140M Motor Grader Service Repair Manual (B9D00001 and up)

$70.00 -

×

Caterpillar CAT 12H NA Motor Grader Service Repair Manual (2WR00001 and up)

$70.00

Caterpillar CAT 12H NA Motor Grader Service Repair Manual (2WR00001 and up)

$70.00 -

×

Caterpillar CAT 14L Motor Grader Service Repair Manual (B9400001 and up)

$80.00

Caterpillar CAT 14L Motor Grader Service Repair Manual (B9400001 and up)

$80.00

Product Guide: Table of Contents & Water Separator Maintenance

Product Overview

This guide provides essential information on maintaining and servicing your equipment, specifically focusing on the water separator maintenance process. Proper care of your machine ensures its longevity and efficiency.

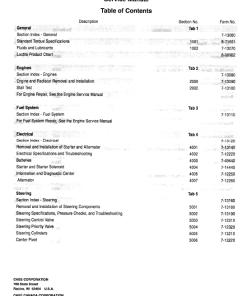

Table of Contents

- Content

- Introduction

- Engine

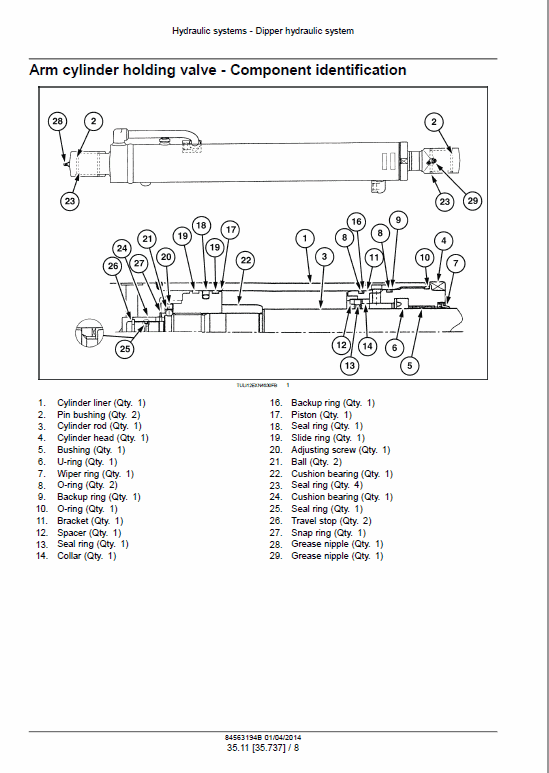

- Hydraulics System

- Frames and Ballasting

- Tracks and Track Suspension

- Electrical System

- Booms, Dippers, and Buckets

- Dozer Blade and Arm

- Platform, Cab, Bodywork, and Decals

- Special Tool Index

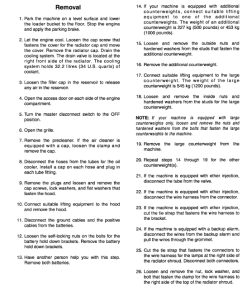

Manual Extract: Water Separator Draining

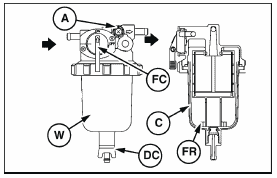

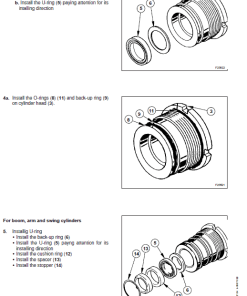

Regular maintenance of the water separator is crucial, especially if significant drainage accumulates, even before scheduled inspections. The semi-transparent cup of the water separator includes a red floating ring (FR) that indicates the drain level. An optional level sensor is available to alert via the gauge cluster.

Draining Instructions

- Step 1: Prepare a waste oil container for collecting waste oil.

- Step 2: Close the fuel cock (FC).

- Step 3: Loosen the drain cock (DC) at the bottom of the water separator to remove collected water.

- Step 4: Manually tighten the drain cock (DC).

- Step 5: Perform air bleeding from the fuel system.

Note:

If no drain appears when opening the drain cock, with the separator possibly higher than the fuel level, loosen the air bleeding bolt (A) by turning it counterclockwise 2-3 times using a screwdriver. Ensure to re-tighten the air bleeding bolt after draining.

Only logged in customers who have purchased this product may leave a review.

Related products

$32.00

$34.00

$35.00

$34.00

Reviews

There are no reviews yet.