Hydraulic System Maintenance Guide

Product Overview

This comprehensive manual provides detailed instructions for the maintenance and handling of stacked control valves used in hydraulic systems. Designed for precision, this guide ensures that all hydraulic equipment is handled with care to maintain its optimal functionality.

Table of Contents

- Content

- Introduction

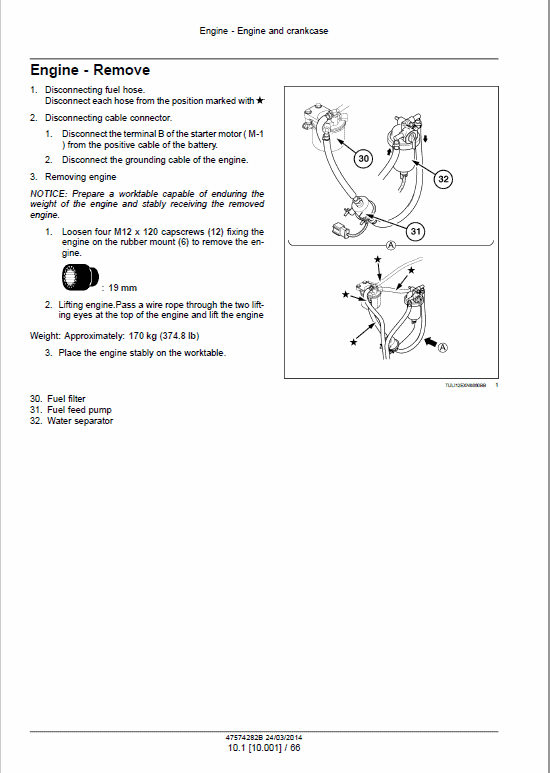

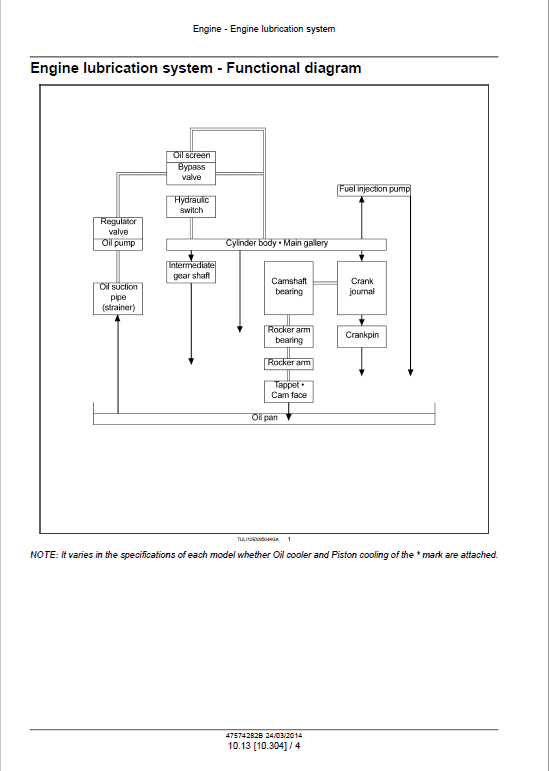

- Engine

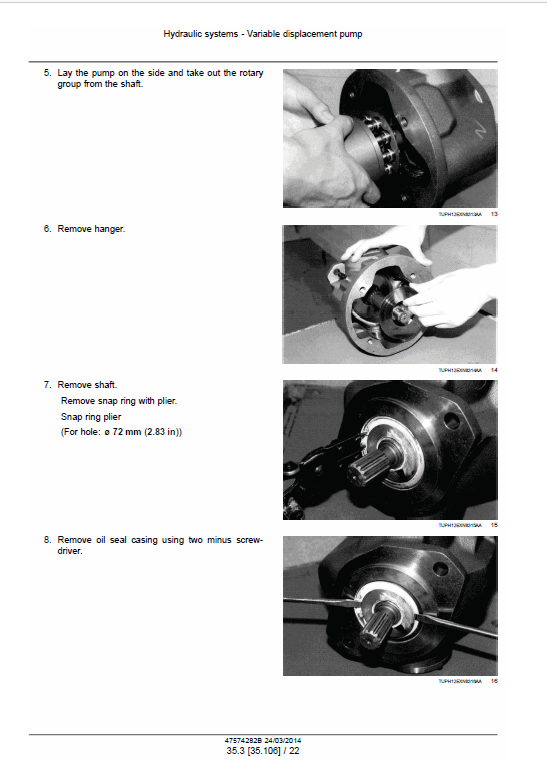

- Hydraulics System

- Frames and Ballasting

- Tracks and Track Suspension

- Cab Climate Control

- Electrical System

- Booms, Dippers, and Buckets

- Dozer Blade and Arm

- Platform, Cab, Bodywork, and Decals

- Special Tools Index

Key Features

- Precision-machined components for minimal clearance and optimal performance.

- Comprehensive disassembly and assembly guidelines to prevent contamination.

- Detailed procedures for transporting and storing hydraulic components.

- Guidance on rust prevention and proper sealing during maintenance operations.

- Post-assembly testing protocols, including relief setting and flow resistance tests.

Benefits

- Ensures long-term reliability of hydraulic systems through proper maintenance practices.

- Protects critical system components from potential damage due to contamination.

- Facilitates safe and effective maintenance work by providing detailed instructions.

Usage Recommendations

- Always perform maintenance in a clean environment to avoid dust and debris entry.

- Prepare and consult valve construction drawings before starting disassembly.

- Cap all hydraulic ports to maintain cleanliness during removal and reassembly.

- Transport the control valve carefully by holding the main body, avoiding contact with exposed surfaces.

- Never attempt to modify equipment without the necessary hydraulic test equipment.

Follow these guidelines to ensure the safe and effective maintenance of hydraulic systems, protecting the integrity and efficiency of your equipment.

Only logged in customers who have purchased this product may leave a review.

Related products

$34.00

$32.00

$33.00

$34.00

Bobcat 2000 Loader Service Manual

Bobcat 2000 Loader Service Manual  Bobcat T250 Loader Service Manual

Bobcat T250 Loader Service Manual  Bobcat T770 Loader Service Manual

Bobcat T770 Loader Service Manual  Tigercat 250B Loader Repair Service Manual (2500501 - 2502000)

Tigercat 250B Loader Repair Service Manual (2500501 - 2502000)

Reviews

There are no reviews yet.