-

×

Yale ERP040DH, ERP050DH, ERP060DH Forklift D216 Series Repair Manual

$34.00

Yale ERP040DH, ERP050DH, ERP060DH Forklift D216 Series Repair Manual

$34.00 -

×

Hitachi ZH200-5A and ZH200LC-5A Excavator Service Repair Manual

$40.00

Hitachi ZH200-5A and ZH200LC-5A Excavator Service Repair Manual

$40.00 -

×

John Deere 4200, 4300, 4400 Compact Utility Tractors Technical Manual

$38.00

John Deere 4200, 4300, 4400 Compact Utility Tractors Technical Manual

$38.00 -

×

JCB JCB305, JS305 Excavator Service Repair Manual

$36.00

JCB JCB305, JS305 Excavator Service Repair Manual

$36.00 -

×

Caterpillar CAT 257B2 Multi Terrain Loader Service Repair Manual (SLK07300 and up)

$70.00

Caterpillar CAT 257B2 Multi Terrain Loader Service Repair Manual (SLK07300 and up)

$70.00 -

×

Yale ESC020AB, ESC025AB, ESC030AB Forklift A824 Service Repair Manual

$25.00

Yale ESC020AB, ESC025AB, ESC030AB Forklift A824 Service Repair Manual

$25.00 -

×

Caterpillar CAT 420F2 Backhoe Loader Service Repair Manual (LYB00001 and up)

$70.00

Caterpillar CAT 420F2 Backhoe Loader Service Repair Manual (LYB00001 and up)

$70.00 -

×

John Deere STX30, STX38, STX46 Lawn Tractors Technical Manual

$29.00

John Deere STX30, STX38, STX46 Lawn Tractors Technical Manual

$29.00 -

×

Yale GDP40VX5, GDP40VX6, GDP45VX6, GDP50VX, GDP55VX Forklift H813 Series Repair Manual

$38.00

Yale GDP40VX5, GDP40VX6, GDP45VX6, GDP50VX, GDP55VX Forklift H813 Series Repair Manual

$38.00 -

×

Yale GDP130EC, GDP140EC, GDP160EC Forklift G877 Series Repair Manual

$35.00

Yale GDP130EC, GDP140EC, GDP160EC Forklift G877 Series Repair Manual

$35.00 -

×

Yale GLP40VX5, GLP40VX6, GLP45VX6, GLP50VX, GLP55VX Forklift J813 Series Repair Manual

$38.00

Yale GLP40VX5, GLP40VX6, GLP45VX6, GLP50VX, GLP55VX Forklift J813 Series Repair Manual

$38.00 -

×

John Deere 6200, 6200L, 6300, 6300L, 6400, 6400L, 6500, 6500L Tractors Repair Manual

$70.00

John Deere 6200, 6200L, 6300, 6300L, 6400, 6400L, 6500, 6500L Tractors Repair Manual

$70.00 -

×

JCB 435 Wheeled Loader Shovel Service Manual

$34.00

JCB 435 Wheeled Loader Shovel Service Manual

$34.00 -

×

CNH VM Motori R 753 IE4 Tier 4B and Stage IV Engine Service Manual

$33.00

CNH VM Motori R 753 IE4 Tier 4B and Stage IV Engine Service Manual

$33.00 -

×

Bobcat 130 Hydraulic Excavator Service Manual

$29.00

Bobcat 130 Hydraulic Excavator Service Manual

$29.00 -

×

JCB 8061 Mini Excavator Service Manual

$33.00

JCB 8061 Mini Excavator Service Manual

$33.00 -

×

Caterpillar CAT 436B Backhoe Loader Service Repair Manual (7FL00600 and up)

$70.00

Caterpillar CAT 436B Backhoe Loader Service Repair Manual (7FL00600 and up)

$70.00 -

×

Fiatallis FR70 Wheel Loader Repair Service Manual

$35.00

Fiatallis FR70 Wheel Loader Repair Service Manual

$35.00 -

×

Case MC1150E Crawler Dozer Service Manual

$32.00

Case MC1150E Crawler Dozer Service Manual

$32.00 -

×

Caterpillar CAT 436B Backhoe Loader Service Repair Manual (6MJ00001 and up)

$70.00

Caterpillar CAT 436B Backhoe Loader Service Repair Manual (6MJ00001 and up)

$70.00 -

×

Caterpillar CAT 428E Backhoe Loader Service Repair Manual (DPH00001 and up)

$70.00

Caterpillar CAT 428E Backhoe Loader Service Repair Manual (DPH00001 and up)

$70.00 -

×

Kobelco SK200-10, SK210-10 Excavator Repair Service Manual

$36.00

Kobelco SK200-10, SK210-10 Excavator Repair Service Manual

$36.00 -

×

Yale GDP080VX, GDP090VX, GDP100VX, GDP110VX, GDP120VX Forklift H813 Series Repair Manual

$38.00

Yale GDP080VX, GDP090VX, GDP100VX, GDP110VX, GDP120VX Forklift H813 Series Repair Manual

$38.00 -

×

Bobcat X220 Excavator Service Manual

$29.00

Bobcat X220 Excavator Service Manual

$29.00 -

×

Yale GDP080VX, GDP090VX, GDP100VX, GDP110VX, GDP120VX Forklift J813 Series Repair Manual

$38.00

Yale GDP080VX, GDP090VX, GDP100VX, GDP110VX, GDP120VX Forklift J813 Series Repair Manual

$38.00 -

×

John Deere G100 and G110 Garden Tractors Technical Manual (TM2020)

$35.00

John Deere G100 and G110 Garden Tractors Technical Manual (TM2020)

$35.00

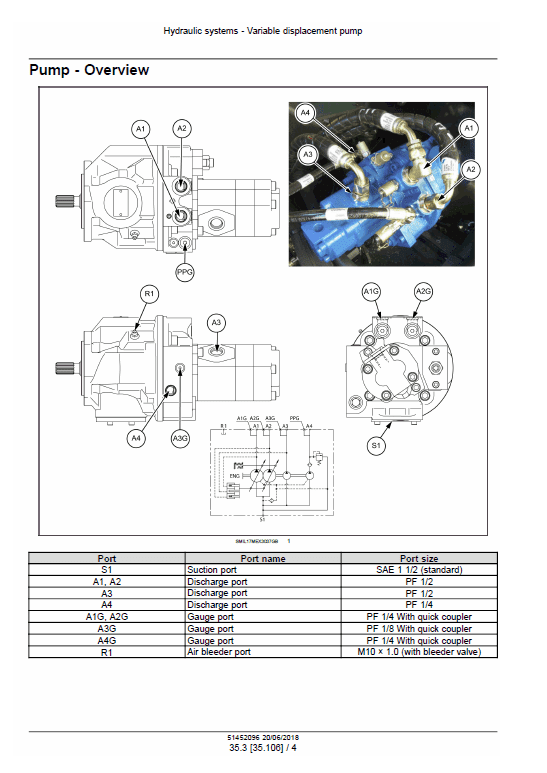

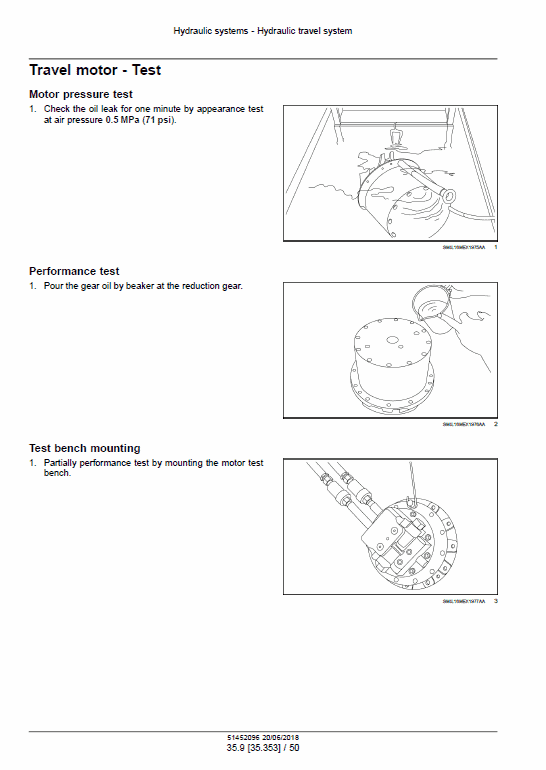

Hydraulic System Service Manual

Product Overview

This comprehensive service manual provides detailed instructions for the maintenance, troubleshooting, and repair of hydraulic systems in machinery. It is essential for ensuring the optimal performance and longevity of your equipment. This manual is especially useful for diagnosing issues when a machine is inoperative despite having a working engine.

Table of Contents

- Content

- Introduction

- Engine

- Hydraulics System

- Pneumatic System

- Frames and Ballasting

- Tracks and Track Suspension

- Cab Climate Control

- Electrical System

- Booms, Dippers, and Buckets

- Dozer Blade and Arm

- Platform, Cab, Bodywork, and Decals

- Electrical Schematic

- Hydraulic Schematic

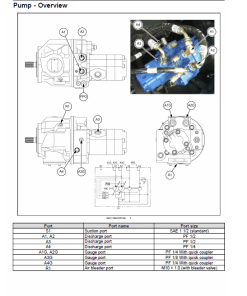

Manual Extract: Hydraulic Systems – Service Instruction – Troubleshooting

Step-by-Step Troubleshooting Guide

For cases of machines being inoperative with the engine still functioning:

-

Check the oil level in the hydraulic oil tank.

- If the oil level is below the lower red line on the level gauge, refill with hydraulic oil to the standard level.

- If the oil level is between the red lines on the level gauge, proceed to step 2.

-

Examine the noise from the hydraulic pump.

- If abnormal noise is present, the hydraulic pump may be broken. Disassemble and repair it.

- If no abnormal noise is detected, continue to step 3.

-

Inspect the noise from the hydraulic pump connections.

- If abnormal noise is detected, the hydraulic pump or engine may be faulty. Refer to the manual for further instructions.

- If no abnormal noise is found, proceed to step 4.

-

Measure the primary pilot pressure.

- If within 2.452 u2013 3.432 MPa (355.663 u2013 497.812 psi), proceed to step 5.

- If outside this range, proceed to step 6.

-

Check for pilot piping clogs and oil leaks.

- If clogging or leaking is found, clean or repair the piping.

- If no issues are detected, the pilot valve may be faulty. Disassemble and repair it.

-

Check the gear pump for oil delivery issues.

- If the gear pump delivers oil, the pilot relief valve may be faulty. Repair or replace it as needed. Refer to the Pump Disassemble (35.106) section.

- If the gear pump does not deliver oil, it is likely broken. Disassemble and repair as instructed in Pump Disassemble (35.106).

Usage Recommendations

- Regularly check and maintain oil levels to ensure efficient system function.

- Monitor for unusual noises which may indicate potential issues.

- Follow the detailed instructions provided in the manual for any repairs or parts replacements.

- Use this manual as a reference for any maintenance activities related to hydraulic systems.

Only logged in customers who have purchased this product may leave a review.

Related products

$32.00

$34.00

$33.50

$34.00

$34.00

$34.00

Reviews

There are no reviews yet.