-

×

Caterpillar CAT 160K Motor Grader Service Repair Manual (JBP00001 and up)

$75.00

Caterpillar CAT 160K Motor Grader Service Repair Manual (JBP00001 and up)

$75.00 -

×

Tigercat 215 Loader Operator Manual (2150101 - 2151000)

$24.00

Tigercat 215 Loader Operator Manual (2150101 - 2151000)

$24.00 -

×

Caterpillar CAT 160H Motor Grader Service Repair Manual (9EJ00001 and up)

$70.00

Caterpillar CAT 160H Motor Grader Service Repair Manual (9EJ00001 and up)

$70.00 -

×

Caterpillar CAT 140M 2 Motor Grader Service Repair Manual (M9J00001 and up)

$70.00

Caterpillar CAT 140M 2 Motor Grader Service Repair Manual (M9J00001 and up)

$70.00 -

×

JCB TM200, TM270, TM300 Wheeled Loader Shovel Service Manual

$34.00

JCB TM200, TM270, TM300 Wheeled Loader Shovel Service Manual

$34.00 -

×

Caterpillar CAT 16G Motor Grader Service Repair Manual (93U02679 and up)

$80.00

Caterpillar CAT 16G Motor Grader Service Repair Manual (93U02679 and up)

$80.00 -

×

Caterpillar CAT 150 Motor Grader Service Repair Manual (ENK00001 and up)

$80.00

Caterpillar CAT 150 Motor Grader Service Repair Manual (ENK00001 and up)

$80.00 -

×

Bobcat T40140, T40170, T40180 Telescopic Handler Service Repair Manual

$40.00

Bobcat T40140, T40170, T40180 Telescopic Handler Service Repair Manual

$40.00 -

×

Caterpillar CAT 140G Motor Grader Service Repair Manual (81V01031 and up)

$70.00

Caterpillar CAT 140G Motor Grader Service Repair Manual (81V01031 and up)

$70.00 -

×

JCB 426, 435, 436, 446 Wheeled Loader Shovel Service Manual

$36.00

JCB 426, 435, 436, 446 Wheeled Loader Shovel Service Manual

$36.00 -

×

Bobcat TR40250 EVO, TR50190 EVO, TR50210 EVO versaHandler Telescopic Service Repair Manual

$36.00

Bobcat TR40250 EVO, TR50190 EVO, TR50210 EVO versaHandler Telescopic Service Repair Manual

$36.00 -

×

Caterpillar CAT 160M SERIES 3 Motor Grader Service Repair Manual (N9E00001 and up)

$70.00

Caterpillar CAT 160M SERIES 3 Motor Grader Service Repair Manual (N9E00001 and up)

$70.00 -

×

Caterpillar CAT 140M 2 Motor Grader Service Repair Manual (R9M00001 and up)

$70.00

Caterpillar CAT 140M 2 Motor Grader Service Repair Manual (R9M00001 and up)

$70.00 -

×

Caterpillar CAT 160G Motor Grader Service Repair Manual (4JD00141 and up)

$75.00

Caterpillar CAT 160G Motor Grader Service Repair Manual (4JD00141 and up)

$75.00 -

×

Caterpillar CAT 130G Motor Grader Service Repair Manual (74V00588 till 01656)

$80.00

Caterpillar CAT 130G Motor Grader Service Repair Manual (74V00588 till 01656)

$80.00 -

×

Tigercat T250B Loader Repair Service Manual (250T0501 - 250T2000)

$34.00

Tigercat T250B Loader Repair Service Manual (250T0501 - 250T2000)

$34.00 -

×

Caterpillar CAT 140B Motor Grader Service Repair Manual (33C00100 and up)

$70.00

Caterpillar CAT 140B Motor Grader Service Repair Manual (33C00100 and up)

$70.00 -

×

Caterpillar CAT 140M 3 AWD Motor Grader Service Repair Manual (N9J00001 and up)

$70.00

Caterpillar CAT 140M 3 AWD Motor Grader Service Repair Manual (N9J00001 and up)

$70.00 -

×

JCB TM180, TM220 Wheeled Loader Service Manual

$35.00

JCB TM180, TM220 Wheeled Loader Service Manual

$35.00 -

×

John Deere 310 Backhoe Repair Technical Manual (TM1036 and TM4290)

$38.00

John Deere 310 Backhoe Repair Technical Manual (TM1036 and TM4290)

$38.00 -

×

John Deere 302A Backhoe Loader Repair Technical Manual (TM1090)

$38.00

John Deere 302A Backhoe Loader Repair Technical Manual (TM1090)

$38.00 -

×

JCB FM30 Mower Service Manual

$30.50

JCB FM30 Mower Service Manual

$30.50 -

×

Caterpillar CAT 140H Motor Grader Service Repair Manual (APM00001 and up)

$80.00

Caterpillar CAT 140H Motor Grader Service Repair Manual (APM00001 and up)

$80.00 -

×

JCB 455ZX Wheeled Loader Shovel Service Manual

$38.00

JCB 455ZX Wheeled Loader Shovel Service Manual

$38.00 -

×

Bobcat B900 Loader Service Repair Manual

$38.00

Bobcat B900 Loader Service Repair Manual

$38.00 -

×

Tigercat 220E Loader Repair Service Manual (2201001 - 2201500)

$38.00

Tigercat 220E Loader Repair Service Manual (2201001 - 2201500)

$38.00 -

×

John Deere 210C, 310C, 315C Backhoe Loader Repair Technical Manual

$38.00

John Deere 210C, 310C, 315C Backhoe Loader Repair Technical Manual

$38.00 -

×

Caterpillar CAT 160H ES Motor Grader Service Repair Manual (6WM00001 and up)

$75.00

Caterpillar CAT 160H ES Motor Grader Service Repair Manual (6WM00001 and up)

$75.00 -

×

Bobcat S220 Skid-Steer Loader Service Manual

$34.00

Bobcat S220 Skid-Steer Loader Service Manual

$34.00 -

×

Caterpillar CAT 12G Motor Grader Service Repair Manual (3WC00001 and up)

$80.00

Caterpillar CAT 12G Motor Grader Service Repair Manual (3WC00001 and up)

$80.00 -

×

Caterpillar CAT 12H Motor Grader Service Repair Manual (AMZ00001 and up)

$80.00

Caterpillar CAT 12H Motor Grader Service Repair Manual (AMZ00001 and up)

$80.00 -

×

Bobcat T3571, T3571L Telescopic Handler Service Repair Manual

$37.00

Bobcat T3571, T3571L Telescopic Handler Service Repair Manual

$37.00 -

×

JCB ZT 20D Mower Service Manual

$28.00

JCB ZT 20D Mower Service Manual

$28.00 -

×

John Deere 710B Backhoe Loader Repair Technical Manual (TM1286)

$39.00

John Deere 710B Backhoe Loader Repair Technical Manual (TM1286)

$39.00 -

×

JCB 412S, 414S, 416S Wheeled Loader Shovel Service Manual

$35.00

JCB 412S, 414S, 416S Wheeled Loader Shovel Service Manual

$35.00 -

×

Caterpillar CAT 14 Motor Grader Service Repair Manual (EN400001 and up)

$80.00

Caterpillar CAT 14 Motor Grader Service Repair Manual (EN400001 and up)

$80.00 -

×

Tigercat 220C Loader Repair Service Manual (2200501 - 2200600)

$34.00

Tigercat 220C Loader Repair Service Manual (2200501 - 2200600)

$34.00

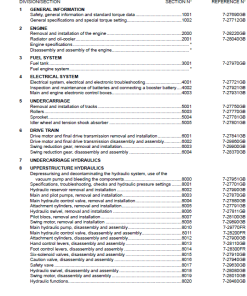

Travel Motor Pre-Conditioning and Maintenance Guide

Product Overview

This guide provides detailed instructions for pre-conditioning and troubleshooting travel motors, ensuring optimal performance and longevity. By following these steps, you can effectively manage air-bleeding within the motor circuit and maintain operational efficiency according to the Operator’s Manual for the Machine Main Unit.

Key Features

- Comprehensive travel motor pre-conditioning operations

- Systematic air-bleeding procedures

- Guidelines for identifying and rectifying abnormal noises

- Instructions for checking and resolving oil leaks

Benefits

- Ensures proper motor functionality and longevity

- Reduces the risk of equipment damage due to air and oil-related issues

- Improves machine efficiency and reliability

Usage Recommendations

- Operate the machine slowly and perform air-bleeding per the Operator’s Manual.

- Check rotation and stopping in both C and A directions at low speeds repeatedly to eliminate air-induced abnormal noises.

- If abnormal noises persist, consider motor replacement.

- Inspect for oil leaks and retighten bolts and line joints to the specified torque where necessary.

- Perform load operation checks to ensure no abnormal vibrations or noises are present.

Additional Notices

Important Safety Precautions:

- Ensure hydraulic devices are stopped before tightening lines after detecting oil leaks.

- Keep operating pressure low when inspecting for oil leaks to prevent oil spray hazards.

Following these guidelines will help maintain the efficiency and safety of your equipment’s travel motor.

Only logged in customers who have purchased this product may leave a review.

Related products

$33.00

$32.00

$35.00

$34.00

$34.00

Reviews

There are no reviews yet.