-

×

AGCO DT180A, DT200A, DT220A, DT240A Tractor Workshop Service Manual

$36.00

AGCO DT180A, DT200A, DT220A, DT240A Tractor Workshop Service Manual

$36.00 -

×

Gehl 521T Wheel Loader Operators and Parts Manual

$30.00

Gehl 521T Wheel Loader Operators and Parts Manual

$30.00 -

×

Gehl 721, 721T Wheel Loader Repair Service Manual

$32.00

Gehl 721, 721T Wheel Loader Repair Service Manual

$32.00 -

×

JCB Vibromax 405, 605, 606 Single Drum Roller Service Manual

$26.65

JCB Vibromax 405, 605, 606 Single Drum Roller Service Manual

$26.65 -

×

Gehl 480T Wheel Steer Loader Repair Service Manual

$33.00

Gehl 480T Wheel Steer Loader Repair Service Manual

$33.00 -

×

Gehl 680 Wheel Loader Repair Service Manual

$33.00

Gehl 680 Wheel Loader Repair Service Manual

$33.00 -

×

Manitou MHT 7140, MHT 10160, MHT 10210L M Series Telehandler Repair Manual

$31.00

Manitou MHT 7140, MHT 10160, MHT 10210L M Series Telehandler Repair Manual

$31.00 -

×

JCB Vibromax 1103 Single Drum Roller Service Manual

$26.50

JCB Vibromax 1103 Single Drum Roller Service Manual

$26.50 -

×

AGCO LT75, LT85, LT90, LT95 Tractor Workshop Repair Manual

$37.00

AGCO LT75, LT85, LT90, LT95 Tractor Workshop Repair Manual

$37.00 -

×

Manitou MHT 10120 L, MHT 10160 L Telehandler Repair Manual

$38.00

Manitou MHT 10120 L, MHT 10160 L Telehandler Repair Manual

$38.00 -

×

JCB 520-50, 525-50 Year 1996 - 2012 Loadall Service Manual

$33.00

JCB 520-50, 525-50 Year 1996 - 2012 Loadall Service Manual

$33.00

Case DV201, DV202, DV204 Vibratory Rollers Service Manual

$34.00

Manual Included: Comprehensive 486-page service manual.

Specifications:

Brand: New Holland

Model: DV201, DV202, DV204

Type: Roller

Manuals: Service Manual

Publication Numbers: 9-54980

Language: English

Format: PDF

Machine Operation and Maintenance Manual

Product Overview

This manual contains important information about the operation and maintenance of the machine. It includes detailed instructions on various components and essential maintenance guidelines. Proper understanding and adherence to these instructions ensure optimal machine performance and longevity.

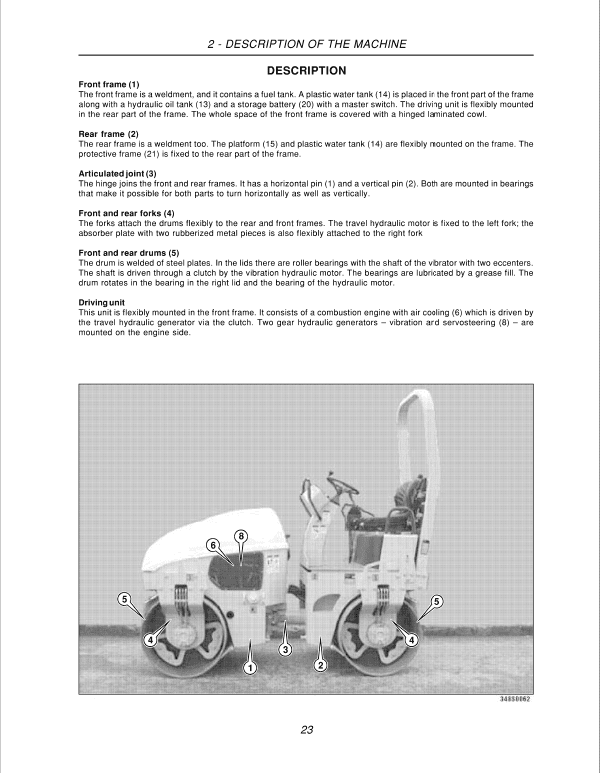

Table of Contents

- General Instructions

- Description of the Machine

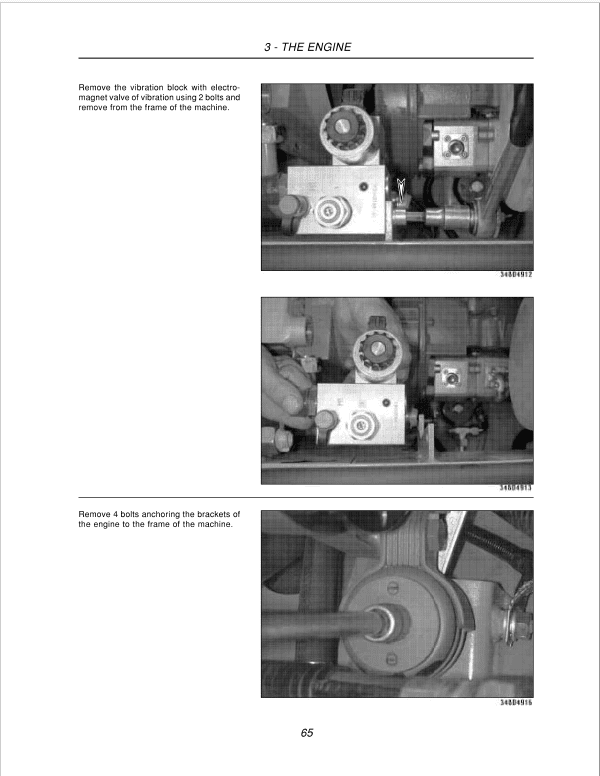

- The Engine

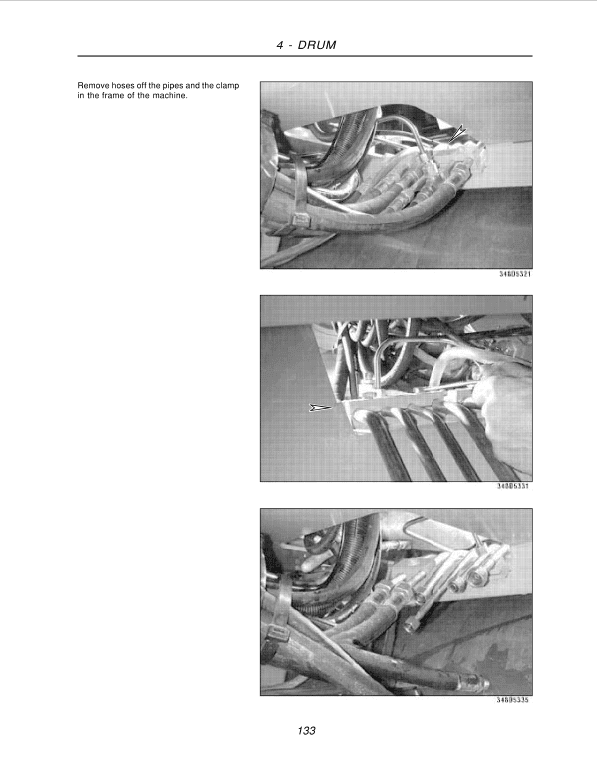

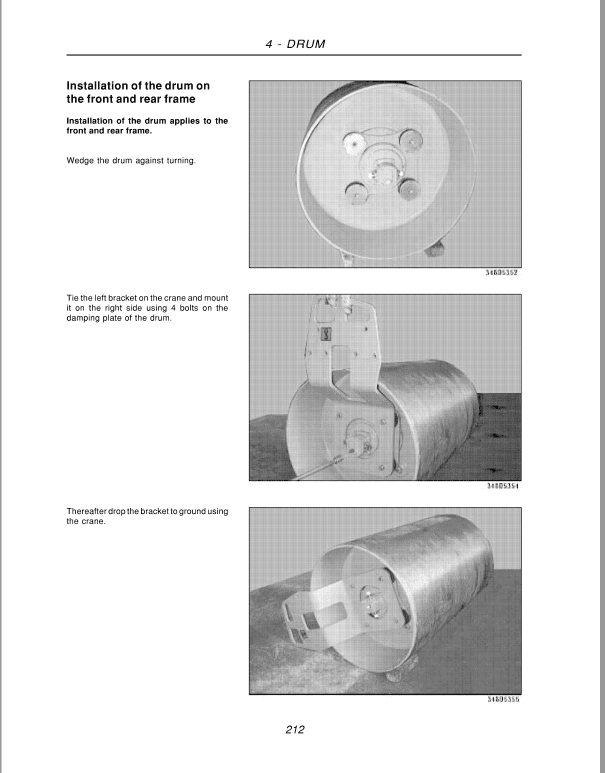

- Drum

- Steering Joint

- Hydraulics

- Control of Gas

- Platform

- The Seat

- The Water Tank

- Sprinkling

- ROPS Frame

- Electrical Wiring

- Appendices

Manual Extract: Grease & Fuel

Grease

For optimal performance, use extreme pressure oil, specifically NLGI Grade 2 or CASE Moly Disulfide grease. This ensures proper lubrication and protection of machine components under high-pressure conditions.

Fuel

- Use fuel that complies with ASTM (American Society for Testing and Materials) D975 standard.

- The recommended fuel is Grade Nu00b02. Using other grades may cause power loss and increase fuel consumption.

- During cold temperatures, a mixture of Nu00b01 and Nu00b02 fuel is permissible. Consult with your fuel vendor for winter fuel requirements specific to your region.

- Take care to avoid conditions where the temperature drops below the fuel cloud point, as wax crystal formation can lead to power loss or engine starting failure.

Important Fuel Handling Tips

- In cold weather, fill the fuel tank at the end of each workday to prevent condensation build-up.

- Extended storage can lead to impurities and condensation in the fuel, causing engine issues. Regularly draining off water and impurities is crucial to maintain fuel quality.

- Store the fuel tank outdoors, keeping the temperature as low as possible to safeguard fuel integrity.

Only logged in customers who have purchased this product may leave a review.

Related products

$33.00

$34.50

$34.00

$35.00

$34.00

$34.00

Reviews

There are no reviews yet.