-

×

Caterpillar CAT CS-683E Vibratory Compactor Service Repair Manual (ASG00001 and up)

$50.00

Caterpillar CAT CS-683E Vibratory Compactor Service Repair Manual (ASG00001 and up)

$50.00 -

×

Kobelco LK450 II Wheel Loader Service Manual

$33.00

Kobelco LK450 II Wheel Loader Service Manual

$33.00 -

×

Sennebogen 825.0.1338 Operators, Maintenance and Parts Manual

$39.00

Sennebogen 825.0.1338 Operators, Maintenance and Parts Manual

$39.00 -

×

New Holland LB90, LB110 Backhoe Loaders Service Manual

$36.00

New Holland LB90, LB110 Backhoe Loaders Service Manual

$36.00 -

×

Caterpillar CAT CS-663E, CP-663E Vibratory Compactor Service Repair Manual (DAF00001 and up)

$50.00

Caterpillar CAT CS-663E, CP-663E Vibratory Compactor Service Repair Manual (DAF00001 and up)

$50.00 -

×

Takeuchi TB153 Compact Excavator Service Manual

$35.00

Takeuchi TB153 Compact Excavator Service Manual

$35.00 -

×

Bobcat 371 Skid-Steer Loader Service Manual

$32.00

Bobcat 371 Skid-Steer Loader Service Manual

$32.00 -

×

New Holland B90B, B95B, B95 BLR, B95 TC Backhoe Loader Service Manual

$34.50

New Holland B90B, B95B, B95 BLR, B95 TC Backhoe Loader Service Manual

$34.50 -

×

Bobcat CT440, CT445 and CT450 Compact Tractor Service Manual

$36.00

Bobcat CT440, CT445 and CT450 Compact Tractor Service Manual

$36.00 -

×

Caterpillar CAT CS-533E, CP-533E Vibratory Compactor Service Repair Manual (ASL00001 and up)

$50.00

Caterpillar CAT CS-533E, CP-533E Vibratory Compactor Service Repair Manual (ASL00001 and up)

$50.00 -

×

Kobelco LK400 Wheel Loader Service Manual

$33.00

Kobelco LK400 Wheel Loader Service Manual

$33.00 -

×

Bobcat S185 Skid-Steer Loader Service Manual

$34.00

Bobcat S185 Skid-Steer Loader Service Manual

$34.00 -

×

JCB 801 Tracked Excavator Service Manual

$30.00

JCB 801 Tracked Excavator Service Manual

$30.00 -

×

Bobcat CT335 Compact Tractor Service Manual

$36.00

Bobcat CT335 Compact Tractor Service Manual

$36.00 -

×

JCB Vibromax VM66 Single Drum Roller Service Manual

$26.65

JCB Vibromax VM66 Single Drum Roller Service Manual

$26.65 -

×

Bobcat 753 and 753HF Skid-Steer Loader Service Manual

$32.00

Bobcat 753 and 753HF Skid-Steer Loader Service Manual

$32.00 -

×

Bobcat 1213 Skid-Steer Loader Service Manual

$32.00

Bobcat 1213 Skid-Steer Loader Service Manual

$32.00 -

×

John Deere 990 Compact Utility Tractors Technical Manual (TM1848)

$30.00

John Deere 990 Compact Utility Tractors Technical Manual (TM1848)

$30.00 -

×

John Deere XUV 620i Gator Utility Vehicle Technical Manual (TM1736)

$39.00

John Deere XUV 620i Gator Utility Vehicle Technical Manual (TM1736)

$39.00 -

×

Kobelco LK500 Wheel Loader Service Manual

$32.50

Kobelco LK500 Wheel Loader Service Manual

$32.50 -

×

John Deere A3 M-Gator Repair Technical Manual (TM115719)

$38.00

John Deere A3 M-Gator Repair Technical Manual (TM115719)

$38.00 -

×

JCB FM25 Mower Service Manual

$30.00

JCB FM25 Mower Service Manual

$30.00 -

×

John Deere 860B Scraper Repair Technical Manual (TM1171)

$38.00

John Deere 860B Scraper Repair Technical Manual (TM1171)

$38.00 -

×

Sennebogen 825.0.1151 Operators, Maintenance and Parts Manual

$39.00

Sennebogen 825.0.1151 Operators, Maintenance and Parts Manual

$39.00 -

×

Caterpillar CAT 120H Motor Grader Service Repair Manual (5FM00001 and up)

$70.00

Caterpillar CAT 120H Motor Grader Service Repair Manual (5FM00001 and up)

$70.00 -

×

John Deere 315SL Backhoe Loader Repair Technical Manual (S.N F273920 - F390995)

$60.00

John Deere 315SL Backhoe Loader Repair Technical Manual (S.N F273920 - F390995)

$60.00 -

×

JCB Midi CX Backhoe Loader Service Manual

$34.00

JCB Midi CX Backhoe Loader Service Manual

$34.00 -

×

John Deere 310SL HL, 410L Backhoe Loader Repair Technical Manual (S.N after F390996 - )

$57.00

John Deere 310SL HL, 410L Backhoe Loader Repair Technical Manual (S.N after F390996 - )

$57.00 -

×

Bobcat T300 Loader Service Manual

$35.00

Bobcat T300 Loader Service Manual

$35.00 -

×

John Deere XUV590i, XUV590i S4 Gator Utility Vehicles Repair Technical Manual

$46.00

John Deere XUV590i, XUV590i S4 Gator Utility Vehicles Repair Technical Manual

$46.00 -

×

Bobcat S175 Skid-Steer Loader Service Manual

$35.00

Bobcat S175 Skid-Steer Loader Service Manual

$35.00 -

×

Sennebogen 305.0.398 (305 C+ & 305 XL) Operators, Maintenance and Parts Manual

$38.00

Sennebogen 305.0.398 (305 C+ & 305 XL) Operators, Maintenance and Parts Manual

$38.00 -

×

Bobcat B780 Loader Service Repair Manual

$38.00

Bobcat B780 Loader Service Repair Manual

$38.00 -

×

Bobcat X337 and X341 Excavator Service Manual

$29.00

Bobcat X337 and X341 Excavator Service Manual

$29.00 -

×

Kobelco LK600A Wheel Loader Service Manual

$32.50

Kobelco LK600A Wheel Loader Service Manual

$32.50 -

×

Caterpillar CAT 14G Motor Grader Service Repair Manual (96U00001 till 01097)

$70.00

Caterpillar CAT 14G Motor Grader Service Repair Manual (96U00001 till 01097)

$70.00 -

×

Bobcat E26 Excavator Repair Service Manual

$38.00

Bobcat E26 Excavator Repair Service Manual

$38.00 -

×

Bobcat BL470, BL475 Loader Service Repair Manual

$38.00

Bobcat BL470, BL475 Loader Service Repair Manual

$38.00 -

×

JCB Vibromax 1105, 1106, 1405, 1805 Single Drum Roller Service Manual

$27.00

JCB Vibromax 1105, 1106, 1405, 1805 Single Drum Roller Service Manual

$27.00 -

×

John Deere 310SL Backhoe Repair Technical Manual (S.N after C273920 & D273920 - 390995)

$61.00

John Deere 310SL Backhoe Repair Technical Manual (S.N after C273920 & D273920 - 390995)

$61.00 -

×

Caterpillar CAT 120H Motor Grader Service Repair Manual (12400001 and up)

$70.00

Caterpillar CAT 120H Motor Grader Service Repair Manual (12400001 and up)

$70.00 -

×

John Deere 310L Backhoe Loader Repair Technical Manual (S.N after F390996 -)

$54.00

John Deere 310L Backhoe Loader Repair Technical Manual (S.N after F390996 -)

$54.00 -

×

John Deere 710L Backhoe Loader Repair Technical Manual (S.N after F390996 -)

$56.00

John Deere 710L Backhoe Loader Repair Technical Manual (S.N after F390996 -)

$56.00 -

×

JCB 411, 416 Wheeled Loader Shovel Service Manual

$34.50

JCB 411, 416 Wheeled Loader Shovel Service Manual

$34.50 -

×

John Deere 310S Backhoe Loader Technical Manual (SN. F273920-)

$59.00

John Deere 310S Backhoe Loader Technical Manual (SN. F273920-)

$59.00 -

×

John Deere 315SG Backhoe Loader Repair Technical Manual (S.N after BE315SG200039 - )

$53.00

John Deere 315SG Backhoe Loader Repair Technical Manual (S.N after BE315SG200039 - )

$53.00 -

×

John Deere 710D Backhoe Loader Repair Technical Manual

$56.00

John Deere 710D Backhoe Loader Repair Technical Manual

$56.00 -

×

John Deere 310K Backhoe Loader Repair Technical Manual (S.N after C000001 - )

$57.00

John Deere 310K Backhoe Loader Repair Technical Manual (S.N after C000001 - )

$57.00 -

×

Sennebogen 830.0.1156 Operators, Maintenance and Parts Manual

$42.00

Sennebogen 830.0.1156 Operators, Maintenance and Parts Manual

$42.00 -

×

Bobcat TL360 and TL360X Telescopic Handler Service Manual

$35.00

Bobcat TL360 and TL360X Telescopic Handler Service Manual

$35.00 -

×

Caterpillar CAT CS-533E, CP-533E Vibratory Compactor Service Repair Manual (DAK00001 and up)

$50.00

Caterpillar CAT CS-533E, CP-533E Vibratory Compactor Service Repair Manual (DAK00001 and up)

$50.00 -

×

John Deere 310L Backhoe Loader Repair Technical Manual (S.N after C000001 & D000001 - )

$53.00

John Deere 310L Backhoe Loader Repair Technical Manual (S.N after C000001 & D000001 - )

$53.00 -

×

John Deere 310K Backhoe Loader Repair Technical Manual (S.N after E219607 - )

$54.00

John Deere 310K Backhoe Loader Repair Technical Manual (S.N after E219607 - )

$54.00 -

×

Sennebogen 825.0.1422 Operators, Maintenance and Parts Manual

$41.00

Sennebogen 825.0.1422 Operators, Maintenance and Parts Manual

$41.00 -

×

Takeuchi TB125, TB135 and TB145 Excavator Service Manual

$36.50

Takeuchi TB125, TB135 and TB145 Excavator Service Manual

$36.50 -

×

John Deere 310SJ Backhoe Loader Repair Technical Manual (S.N before - 159759)

$53.00

John Deere 310SJ Backhoe Loader Repair Technical Manual (S.N before - 159759)

$53.00 -

×

Bobcat E45 Compact Excavator Service Manual

$36.00

Bobcat E45 Compact Excavator Service Manual

$36.00 -

×

Bobcat E35i Excavator Repair Service Manual

$35.00

Bobcat E35i Excavator Repair Service Manual

$35.00 -

×

Yale GDP030AF, GDP040AF Forklift A810 Service Repair Manual

$34.00

Yale GDP030AF, GDP040AF Forklift A810 Service Repair Manual

$34.00 -

×

Caterpillar CAT 18M3 Motor Grader Service Repair Manual (N9A00001 and up)

$70.00

Caterpillar CAT 18M3 Motor Grader Service Repair Manual (N9A00001 and up)

$70.00 -

×

John Deere 510 Backhoe Loader Repair Technical Manual (TM1039)

$38.00

John Deere 510 Backhoe Loader Repair Technical Manual (TM1039)

$38.00 -

×

Caterpillar CAT 140 Motor Grader Service Repair Manual (ENH00001 and up)

$80.00

Caterpillar CAT 140 Motor Grader Service Repair Manual (ENH00001 and up)

$80.00 -

×

Sennebogen 825.0.1352 Operators, Maintenance and Parts Manual

$41.00

Sennebogen 825.0.1352 Operators, Maintenance and Parts Manual

$41.00 -

×

JCB 3CX, 4CX, 214, 215, 217 Loader Service Repair Manual (460001 to 499999 & 900001 - 929999)

$35.00

JCB 3CX, 4CX, 214, 215, 217 Loader Service Repair Manual (460001 to 499999 & 900001 - 929999)

$35.00 -

×

Caterpillar CAT 140M Motor Grader Service Repair Manual (D9G00001 and up)

$70.00

Caterpillar CAT 140M Motor Grader Service Repair Manual (D9G00001 and up)

$70.00 -

×

John Deere 300D, 310D, 315D Backhoe Loader Repair Technical Manual

$52.00

John Deere 300D, 310D, 315D Backhoe Loader Repair Technical Manual

$52.00 -

×

John Deere 310K EP Backhoe Loader Repair Technical Manual (S.N after G219607 - )

$57.00

John Deere 310K EP Backhoe Loader Repair Technical Manual (S.N after G219607 - )

$57.00 -

×

Bobcat 700, 720, 721 and 722 Skid-Steer Loader Service Manual

$32.00

Bobcat 700, 720, 721 and 722 Skid-Steer Loader Service Manual

$32.00 -

×

Takeuchi TB235 Compact Excavator Service Manual

$35.00

Takeuchi TB235 Compact Excavator Service Manual

$35.00 -

×

John Deere 315SJ Backhoe Loader Repair Technical Manual (S.N before - BE315SJ300868 )

$59.00

John Deere 315SJ Backhoe Loader Repair Technical Manual (S.N before - BE315SJ300868 )

$59.00 -

×

Bobcat E10 Excavator Repair Service Manual

$36.00

Bobcat E10 Excavator Repair Service Manual

$36.00 -

×

John Deere 410K Backhoe Loader Repair Technical Manual (S.N after C219607 & D219607 - )

$59.00

John Deere 410K Backhoe Loader Repair Technical Manual (S.N after C219607 & D219607 - )

$59.00 -

×

Caterpillar CAT CP-533C, CS-533C Vibratory Compactor Service Repair Manual (2XN00001 and up)

$50.00

Caterpillar CAT CP-533C, CS-533C Vibratory Compactor Service Repair Manual (2XN00001 and up)

$50.00 -

×

Caterpillar CAT 120M SERIES 2 OEM Motor Grader Service Repair Manual (M9200001 and up)

$80.00

Caterpillar CAT 120M SERIES 2 OEM Motor Grader Service Repair Manual (M9200001 and up)

$80.00

Case Farmall 40B CVT, 45B CVT, 50B CVT Tractor Service Manual

$36.00

Explore the comprehensive Service Manual specifically designed for Case tractors, including the Farmall 40B CVT, 45B CVT, and 50B CVT models. This manual is an essential resource for detailed service and maintenance procedures.

Key Specifications:

Fuel Injectors – Dynamic Description

Product Overview

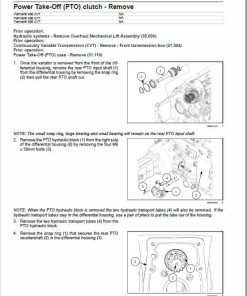

This manual provides comprehensive details on throttle-type fuel injectors used in various engine applications. These injectors are specifically designed to deliver fuel into pressurized cylinders, optimizing combustion efficiency and minimizing smoke production.

Key Features

- Orifice Size: Each injector features a 1.0 mm (0.04 in) single orifice.

- Pressure Setting: Injectors are set at a pressure of 14824 kPa (2150 psi) and pressure adjustments are facilitated through shim modifications.

- Injection Angle: Engineered with a precise injection angle of 4u00b0.

- Uniform Injector Pipes: All injectors use pipes of equal length to ensure consistent fuel injection intervals across cylinders.

Benefits

- Efficient Combustion: Maximizes fuel atomization for improved combustion and reduced smoke.

- Durable Design: The injector assembly comprises a robust nozzle and needle valve setup to ensure longevity and reliability.

- Consistent Performance: Engineered for optimal performance with a uniform distribution of fuel to all cylinders.

- Fuel Economy: Enhances engine performance while conserving fuel through advanced injection technology.

Usage Recommendations

- Adjustment and Maintenance: Modify pressure using shims to maintain optimal injector performance based on specific engine requirements.

- Ensure Proper Lubrication: Allow for a small fuel leakage to lubricate the injector components, preventing wear and tear.

- Check Injector Pipes: Regularly inspect for uniformity in length to support precise fuel injection timing.

Fuel from the injection pump enters through the injector inlet, passing through a precise drilling in the nozzle holder to reach the needle valve seat. Pressurized fuel lifts the needle valve, allowing atomized fuel to be discharged through the orifice and ensuring optimum engine operation. Excess fuel serves as lubrication and returns to the fuel tank through an injection leak-off line.

Only logged in customers who have purchased this product may leave a review.

Related products

$34.00

$34.00

$34.00

$34.00

$34.50

$34.00

$34.00

Reviews

There are no reviews yet.