-

×

Caterpillar CAT 906H Compact Wheel Loader Service Repair Manual (TPE00001 and up)

$70.00

Caterpillar CAT 906H Compact Wheel Loader Service Repair Manual (TPE00001 and up)

$70.00 -

×

Liebherr L580 Type 1495 Wheel Loader Service Manual

$34.50

Liebherr L580 Type 1495 Wheel Loader Service Manual

$34.50 -

×

Fiat 570, 570DT, 670, 670DT Tractor Service Manual

$21.00

Fiat 570, 570DT, 670, 670DT Tractor Service Manual

$21.00 -

×

Caterpillar CAT CS-683E Vibratory Compactor Service Repair Manual (AGR00001 and up)

$50.00

Caterpillar CAT CS-683E Vibratory Compactor Service Repair Manual (AGR00001 and up)

$50.00 -

×

John Deere 7210, 7410, 7510 Tractors Service Repair Manual (TM1653 and TM1654)

$65.00

John Deere 7210, 7410, 7510 Tractors Service Repair Manual (TM1653 and TM1654)

$65.00 -

×

Fiat 450, 450DT Tractor Workshop Service Manual

$22.00

Fiat 450, 450DT Tractor Workshop Service Manual

$22.00 -

×

Caterpillar CAT D4 Track-Type Tractor Service Repair Manual (JPH00001 and up)

$65.00

Caterpillar CAT D4 Track-Type Tractor Service Repair Manual (JPH00001 and up)

$65.00 -

×

Kubota L3240, L3540, L4240, L5040, L5240, L5740 Tractors Service Manual

$35.00

Kubota L3240, L3540, L4240, L5040, L5240, L5740 Tractors Service Manual

$35.00 -

×

Hitachi ZX55U-5A Mini Excavator Service Repair Manual

$49.00

Hitachi ZX55U-5A Mini Excavator Service Repair Manual

$49.00 -

×

Caterpillar CAT D6 Track-Type Tractor Service Repair Manual (LNC00001 and up)

$70.00

Caterpillar CAT D6 Track-Type Tractor Service Repair Manual (LNC00001 and up)

$70.00 -

×

New Holland TL70, TL80, TL90, TL100 Tractor Service Manual

$36.00

New Holland TL70, TL80, TL90, TL100 Tractor Service Manual

$36.00 -

×

Yale MPC080E Pallet A905 Service Repair Manual

$30.00

Yale MPC080E Pallet A905 Service Repair Manual

$30.00 -

×

Kobelco SK230SRLC-3 Hydraulic Excavator Repair Service Manual

$34.00

Kobelco SK230SRLC-3 Hydraulic Excavator Repair Service Manual

$34.00 -

×

Caterpillar CAT 906 C Wheel Loader Service Repair Manual (MER00001 and up)

$70.00

Caterpillar CAT 906 C Wheel Loader Service Repair Manual (MER00001 and up)

$70.00 -

×

Case Optum 270 CVT, 300 CVT Tractor Service Manual

$42.00

Case Optum 270 CVT, 300 CVT Tractor Service Manual

$42.00 -

×

Liebherr L556 Type 1289 Wheel Loader Service Manual

$35.00

Liebherr L556 Type 1289 Wheel Loader Service Manual

$35.00 -

×

Caterpillar CAT 924G, 924GZ Wheel Loader Service Repair Manual (DFZ00001 till 00563)

$65.00

Caterpillar CAT 924G, 924GZ Wheel Loader Service Repair Manual (DFZ00001 till 00563)

$65.00 -

×

Kobelco MD140C Excavator Service Manual

$35.00

Kobelco MD140C Excavator Service Manual

$35.00 -

×

New Holland F4CE0354A 334T M2 Engine Service Manual

$25.00

New Holland F4CE0354A 334T M2 Engine Service Manual

$25.00 -

×

Caterpillar CAT D3K2 XL Track-Type Tractor Service Repair Manual (KF200001 and up)

$70.00

Caterpillar CAT D3K2 XL Track-Type Tractor Service Repair Manual (KF200001 and up)

$70.00 -

×

John Deere 4620 Tractor Repair Technical Manual

$30.00

John Deere 4620 Tractor Repair Technical Manual

$30.00 -

×

Kobelco SK210LC-9 Hydraulic Excavator Repair Service Manual

$36.00

Kobelco SK210LC-9 Hydraulic Excavator Repair Service Manual

$36.00 -

×

Kobelco MD200C Excavator Service Manual

$35.00

Kobelco MD200C Excavator Service Manual

$35.00 -

×

John Deere 6105E, 6120E, 6120EH, 6135E Repair Manual (001001 - Current)

$65.00

John Deere 6105E, 6120E, 6120EH, 6135E Repair Manual (001001 - Current)

$65.00 -

×

Case 480 B Tractor Service Manual

$34.00

Case 480 B Tractor Service Manual

$34.00 -

×

Caterpillar CAT D3G Track-Type Tractor Service Repair Manual (CXT00001 and up)

$70.00

Caterpillar CAT D3G Track-Type Tractor Service Repair Manual (CXT00001 and up)

$70.00 -

×

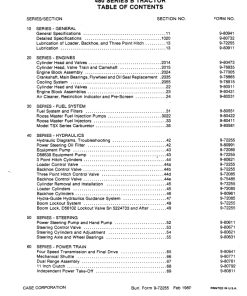

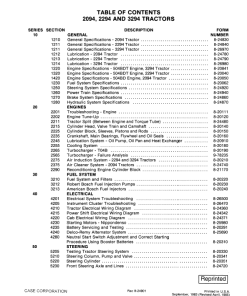

Case 2094, 2294, 3294 Tractor Service Manual

$36.00

Case 2094, 2294, 3294 Tractor Service Manual

$36.00 -

×

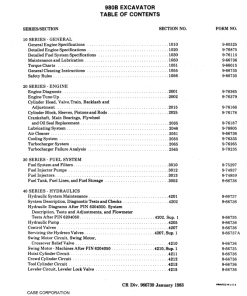

Case 980B Excavator Service Manual

$34.00

Case 980B Excavator Service Manual

$34.00 -

×

Kobelco SK400-IV, SK400LC-IV Excavator Service Manual

$36.00

Kobelco SK400-IV, SK400LC-IV Excavator Service Manual

$36.00 -

×

Case 2050M Crawler Dozer Service Manual

$40.00

Case 2050M Crawler Dozer Service Manual

$40.00 -

×

Caterpillar CAT D11T Track Type Tractor Service Repair Manual (JEL00001 and up)

$70.00

Caterpillar CAT D11T Track Type Tractor Service Repair Manual (JEL00001 and up)

$70.00 -

×

Fiat 580, 580DT, 680, 680DT Tractor Service Manual

$26.00

Fiat 580, 580DT, 680, 680DT Tractor Service Manual

$26.00 -

×

Caterpillar CAT 951B, 951C Track Loader Service Repair Manual (86J01992 till 02597)

$70.00

Caterpillar CAT 951B, 951C Track Loader Service Repair Manual (86J01992 till 02597)

$70.00 -

×

John Deere SE 6200, SE 6300, SE 6400 Tractors Service Repair Manual (TM4487 and TM4493)

$75.00

John Deere SE 6200, SE 6300, SE 6400 Tractors Service Repair Manual (TM4487 and TM4493)

$75.00 -

×

Caterpillar CAT D5G Track-Type Tractor Service Repair Manual (RKG00001 and up)

$80.00

Caterpillar CAT D5G Track-Type Tractor Service Repair Manual (RKG00001 and up)

$80.00 -

×

Liebherr L550 Type 1214 Wheel Loader Service Manual

$36.00

Liebherr L550 Type 1214 Wheel Loader Service Manual

$36.00 -

×

Caterpillar CAT D4C II Track-Type Tractor Service Repair Manual (9BG00001 and up)

$70.00

Caterpillar CAT D4C II Track-Type Tractor Service Repair Manual (9BG00001 and up)

$70.00 -

×

Caterpillar CAT D3C II Track-Type Tractor Service Repair Manual (7JG00001 and up)

$65.00

Caterpillar CAT D3C II Track-Type Tractor Service Repair Manual (7JG00001 and up)

$65.00 -

×

Case CX35B, CX39B Series 2 Mini Excavator Service Manual

$36.00

Case CX35B, CX39B Series 2 Mini Excavator Service Manual

$36.00 -

×

Caterpillar CAT D5B Track-Type Tractor Service Repair Manual (44X00001 and up)

$70.00

Caterpillar CAT D5B Track-Type Tractor Service Repair Manual (44X00001 and up)

$70.00 -

×

Kobelco SK30SR-5, SK35SR-5 Hydraulic Excavator Repair Service Manual

$35.00

Kobelco SK30SR-5, SK35SR-5 Hydraulic Excavator Repair Service Manual

$35.00 -

×

John Deere 110 Excavator Repair Technical Manual

$51.00

John Deere 110 Excavator Repair Technical Manual

$51.00 -

×

Kobelco SK485-8 Tier 3 Crawler Excavator Repair Service Manual

$34.00

Kobelco SK485-8 Tier 3 Crawler Excavator Repair Service Manual

$34.00 -

×

Hitachi ZX40U-2, ZX50U-2 Excavator Service Repair Manual

$48.00

Hitachi ZX40U-2, ZX50U-2 Excavator Service Repair Manual

$48.00 -

×

Ford 100, 120, 125, 145, 165, 195 Lawn Tractor Service Manual

$27.00

Ford 100, 120, 125, 145, 165, 195 Lawn Tractor Service Manual

$27.00 -

×

Caterpillar CAT D4 Track-Type Tractor Service Repair Manual (RKR00001 and up)

$70.00

Caterpillar CAT D4 Track-Type Tractor Service Repair Manual (RKR00001 and up)

$70.00 -

×

Caterpillar CAT D5M Track-Type Tractor Service Repair Manual (5ES00001 and up)

$65.00

Caterpillar CAT D5M Track-Type Tractor Service Repair Manual (5ES00001 and up)

$65.00 -

×

John Deere 5203S, 5310, 5310S, 5410, 5610 Tractors Tractors Repair Manual (India)

$55.00

John Deere 5203S, 5310, 5310S, 5410, 5610 Tractors Tractors Repair Manual (India)

$55.00 -

×

Kobelco SK350LC-9E Hydraulic Excavator Repair Service Manual

$38.00

Kobelco SK350LC-9E Hydraulic Excavator Repair Service Manual

$38.00 -

×

John Deere X940, X948, X949 Lawn Tractor Repair Manual (S.N 060001 - ) (TM147919)

$44.00

John Deere X940, X948, X949 Lawn Tractor Repair Manual (S.N 060001 - ) (TM147919)

$44.00 -

×

Yale MPC080E Pallet A892 Service Repair Manual

$20.00

Yale MPC080E Pallet A892 Service Repair Manual

$20.00 -

×

Kobelco SK135SR-3, SK135SRLC-3, SK140SR-3, SK140SRL-3 Excavator Service Manual

$35.00

Kobelco SK135SR-3, SK135SRLC-3, SK140SR-3, SK140SRL-3 Excavator Service Manual

$35.00 -

×

New Holland 3510, 4010, 4510, 4710 Tractor Service Manual

$34.00

New Holland 3510, 4010, 4510, 4710 Tractor Service Manual

$34.00 -

×

Caterpillar CAT CS-583C Vibratory Compactor Service Repair Manual (7MN00001 and up)

$50.00

Caterpillar CAT CS-583C Vibratory Compactor Service Repair Manual (7MN00001 and up)

$50.00 -

×

John Deere 240, 245, 260, 265, 285, 320 Lawn Garden Tractors Technical Manual

$28.00

John Deere 240, 245, 260, 265, 285, 320 Lawn Garden Tractors Technical Manual

$28.00 -

×

Kobelco SK310 and SK310LC Excavator Service Manual

$35.00

Kobelco SK310 and SK310LC Excavator Service Manual

$35.00 -

×

New Holland E55Bx Tier 3 Compact Excavator Service Manual

$34.00

New Holland E55Bx Tier 3 Compact Excavator Service Manual

$34.00 -

×

Hitachi ZX20U-5A Excavator Service Repair Manual

$45.00

Hitachi ZX20U-5A Excavator Service Repair Manual

$45.00 -

×

Hitachi ZW30, ZW40, ZW50 Wheel Loader Service Repair Manual

$33.00

Hitachi ZW30, ZW40, ZW50 Wheel Loader Service Repair Manual

$33.00 -

×

Hitachi ZW120-5B Wheel Loader Service Repair Manual

$33.00

Hitachi ZW120-5B Wheel Loader Service Repair Manual

$33.00 -

×

Case SR270 Skid Steer Loader Tier 4B Parts Catalog Manual

$50.00

Case SR270 Skid Steer Loader Tier 4B Parts Catalog Manual

$50.00 -

×

New Holland TK4020F, TK4020V, TK4030, TK4040, TK4040M Tractor Manual

$34.00

New Holland TK4020F, TK4020V, TK4030, TK4040, TK4040M Tractor Manual

$34.00 -

×

Yale ERP040DH, ERP050DH, ERP060DH, ERP065DH Forklift E216 Series Repair Manual

$35.00

Yale ERP040DH, ERP050DH, ERP060DH, ERP065DH Forklift E216 Series Repair Manual

$35.00 -

×

Bobcat T3071, T3071CD, T3093S, T3093CD versaHANDLER Telescopic Operation Manual

$31.00

Bobcat T3071, T3071CD, T3093S, T3093CD versaHANDLER Telescopic Operation Manual

$31.00 -

×

Hino 145, 165, 185, 238, 268, 338 Series Year 2006 Repair Manual

$35.00

Hino 145, 165, 185, 238, 268, 338 Series Year 2006 Repair Manual

$35.00

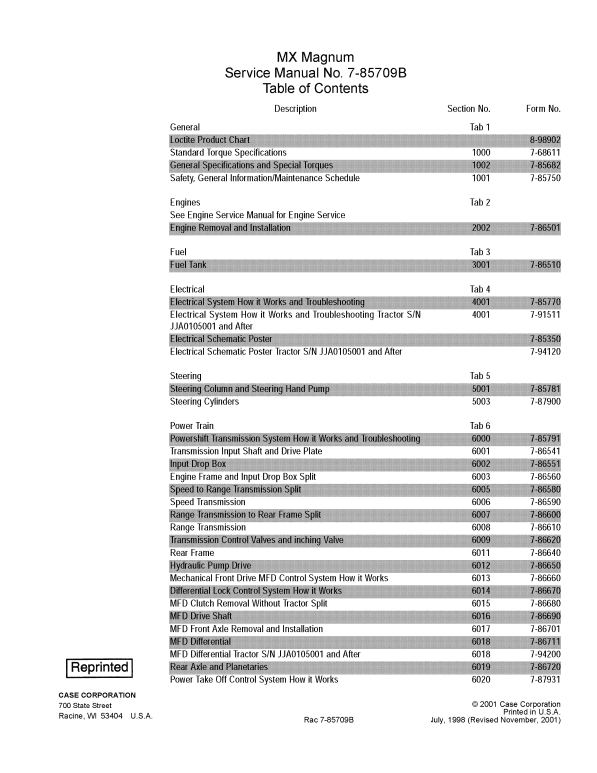

Case MX180, MX200, MX220, MX240, MX270 Tractor Service Manual

$36.50

Ensure the optimal performance of your Case tractors with this comprehensive service manual. Covering models MX180, MX200, MX220, MX240, and MX270, it is an essential resource for maintenance and repairs.

Comprehensive Equipment Manual

Product Overview

This manual provides detailed information on various components of heavy-duty machinery, offering in-depth guidance on system operations and procedures. It serves as a key resource for understanding the mechanical and technical aspects critical to maintenance and troubleshooting. This document is tailored specifically for the Case MX series, including models MX180, MX200, MX220, MX240, and MX270.

Key Features

- Systematic Organization: The manual is divided into distinct sections that cover major mechanical systems and components, ensuring users can easily navigate to relevant information.

- Technical Details: Each section delves into specific systems and components, providing step-by-step guidance and expert insights.

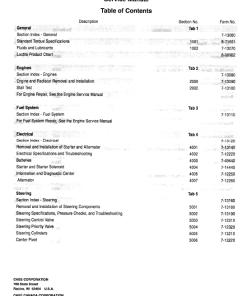

Table of Contents

- General

- Engine

- Fuel

- Electrical

- Steering

- Power Train

- Brakes

- Hydraulics

- Chassis

- Controller Systems

Manual Extract

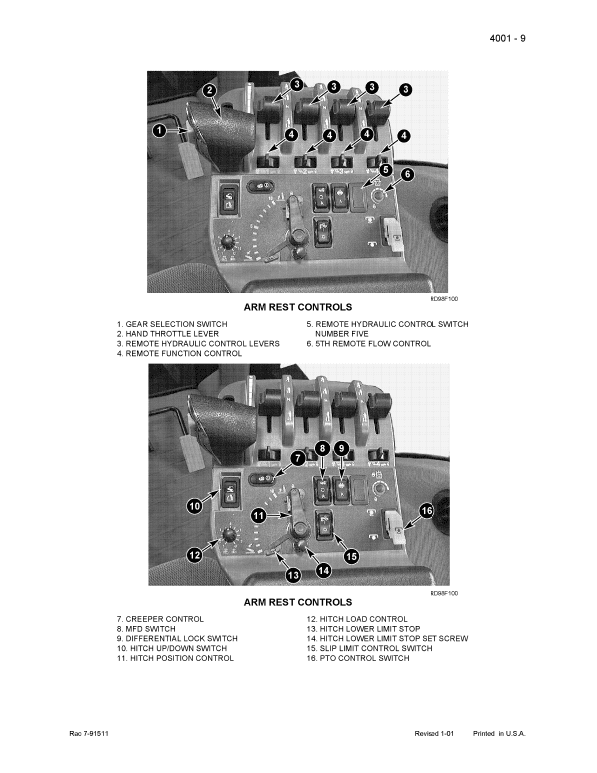

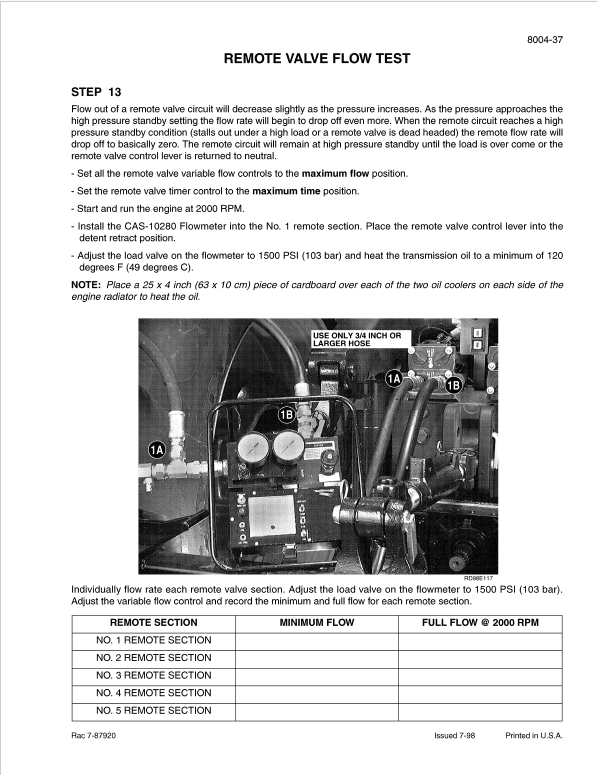

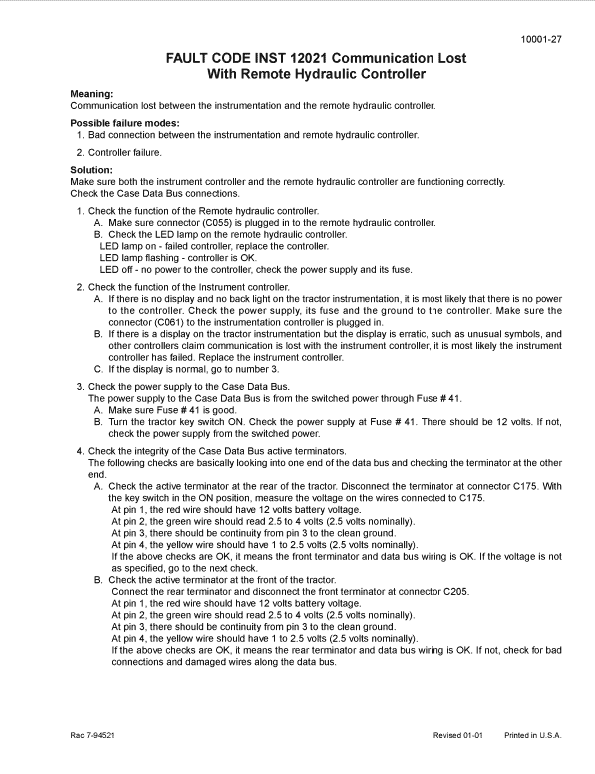

The process of moving the remote hydraulic control lever to the retract position initiates the shift of the main valve spool to the right, managed by a proportional solenoid pressure supply. This movement determines the flow rate to the retract port.

As the main valve spool shifts, it directs flow from the intermediate pressure area to the lower port and the left-hand side of the load check plunger. This results in the rightward movement of the plunger, unseating the load check pilot poppet, and relieving pressure on the spring side of the main poppet back to the tank. Consequently, this action unseats the main poppet, facilitating the return oil flow back to the inlet side of the filter base. The differential pressure between the raise port and the spring side of the main poppet aids in this unseating process.

Simultaneously, work pressure is communicated to the signal check through a center-drilled passage in the main valve spool, activating the signal pressure directed to the pump compensator to increase the PFC pump flow.

Usage Recommendations

- Utilize this manual for troubleshooting and understanding hydraulic control operations.

- Ensure routine checks and maintenance align with the procedural guidelines provided.

- Reference the detailed sections for comprehensive system diagnostics and repairs.

Only logged in customers who have purchased this product may leave a review.

Related products

$33.50

$34.00

$33.00

$34.00

$34.00

$34.00

$35.00

Reviews

There are no reviews yet.