-

×

Bobcat 3400, 3400XL Utility Vehicle Service Repair Manual

$37.00

Bobcat 3400, 3400XL Utility Vehicle Service Repair Manual

$37.00 -

×

Komatsu 930E-4SE Dump Truck Service Repair Manual

$44.00

Komatsu 930E-4SE Dump Truck Service Repair Manual

$44.00 -

×

Volvo DD138HFA Asphalt Compactors Repair Service Manual

$37.00

Volvo DD138HFA Asphalt Compactors Repair Service Manual

$37.00 -

×

Volvo L120G Wheel Loader Repair Service Manual

$59.00

Volvo L120G Wheel Loader Repair Service Manual

$59.00 -

×

Bobcat V518 VersaHANDLER Telescopic Service Manual

$35.00

Bobcat V518 VersaHANDLER Telescopic Service Manual

$35.00 -

×

Komatsu PC40MRX-1, PC45MRX-1 Excavator Service Manual

$35.00

Komatsu PC40MRX-1, PC45MRX-1 Excavator Service Manual

$35.00 -

×

Bobcat 641, 642 and 643 Skid-Steer Loader Service Manual

$32.00

Bobcat 641, 642 and 643 Skid-Steer Loader Service Manual

$32.00 -

×

Toyota 5FG10, 5FG14, 5FG15, 5FG18, 5FG20 Forklift Service Repair Manual

$36.00

Toyota 5FG10, 5FG14, 5FG15, 5FG18, 5FG20 Forklift Service Repair Manual

$36.00 -

×

Volvo L150H Wheel Loader Repair Service Manual

$70.00

Volvo L150H Wheel Loader Repair Service Manual

$70.00 -

×

Toyota 6FG23, 6FG25, 6FG28, 6FG30 Forklift Service Repair Manual

$36.00

Toyota 6FG23, 6FG25, 6FG28, 6FG30 Forklift Service Repair Manual

$36.00 -

×

Volvo PT220C Asphalt Compactors Repair Service Manual

$43.00

Volvo PT220C Asphalt Compactors Repair Service Manual

$43.00 -

×

Volvo L150G Wheel Loader Repair Service Manual

$59.00

Volvo L150G Wheel Loader Repair Service Manual

$59.00 -

×

Bobcat V638 VersaHANDLER Telescopic Service Manual

$35.00

Bobcat V638 VersaHANDLER Telescopic Service Manual

$35.00 -

×

Komatsu HD465-7, HD605-7 Dump Truck Service Repair Manual

$38.00

Komatsu HD465-7, HD605-7 Dump Truck Service Repair Manual

$38.00 -

×

Case 340 Articulated Truck Service Manual

$34.00

Case 340 Articulated Truck Service Manual

$34.00 -

×

Komatsu SK1020-5 Skid-Steer Loader Service Manual

$34.00

Komatsu SK1020-5 Skid-Steer Loader Service Manual

$34.00 -

×

Toyota SDK10 Skid Steer Loader Repair Manual

$36.00

Toyota SDK10 Skid Steer Loader Repair Manual

$36.00 -

×

Daewoo D24NAP Engine Operation and Maintenance Manual

$24.00

Daewoo D24NAP Engine Operation and Maintenance Manual

$24.00 -

×

Case 788, 988 Plus Excavator Service Manual

$35.00

Case 788, 988 Plus Excavator Service Manual

$35.00 -

×

Bobcat E35i Excavator Repair Service Manual

$35.00

Bobcat E35i Excavator Repair Service Manual

$35.00 -

×

Case WX210 and WX240 Excavator Service Manual

$35.00

Case WX210 and WX240 Excavator Service Manual

$35.00 -

×

Case 480 B Tractor Service Manual

$34.00

Case 480 B Tractor Service Manual

$34.00 -

×

Volvo DD138HA Asphalt Compactors Repair Service Manual

$37.00

Volvo DD138HA Asphalt Compactors Repair Service Manual

$37.00 -

×

Bobcat E45 Compact Excavator Service Manual

$36.00

Bobcat E45 Compact Excavator Service Manual

$36.00 -

×

Komatsu CK30-1 Skid-Steer Loader Service Manual

$34.00

Komatsu CK30-1 Skid-Steer Loader Service Manual

$34.00 -

×

Volvo DD14S Asphalt Compactors Repair Service Manual

$25.00

Volvo DD14S Asphalt Compactors Repair Service Manual

$25.00 -

×

Cameco SP1850 Loader Repair Service Manual

$31.00

Cameco SP1850 Loader Repair Service Manual

$31.00 -

×

Caterpillar CAT 320D2, 320D2 L Excavator Service Repair Manual (RAR00001 and up)

$70.00

Caterpillar CAT 320D2, 320D2 L Excavator Service Repair Manual (RAR00001 and up)

$70.00 -

×

Bobcat E34 Excavator Repair Service Manual

$36.00

Bobcat E34 Excavator Repair Service Manual

$36.00 -

×

Bobcat T450 Compact Track Loader Service Repair Manual

$36.00

Bobcat T450 Compact Track Loader Service Repair Manual

$36.00 -

×

Bobcat T300 Loader Service Manual

$35.00

Bobcat T300 Loader Service Manual

$35.00 -

×

Caterpillar CAT 245B Excavator Service Repair Manual (6MF00001 till 00512)

$70.00

Caterpillar CAT 245B Excavator Service Repair Manual (6MF00001 till 00512)

$70.00 -

×

Caterpillar CAT 306E Mini Hydraulic Excavator Service Repair Manual (FHL00001 and up)

$70.00

Caterpillar CAT 306E Mini Hydraulic Excavator Service Repair Manual (FHL00001 and up)

$70.00 -

×

AGCO Allis 8745, 8765 Tractors Service Manual

$34.00

AGCO Allis 8745, 8765 Tractors Service Manual

$34.00 -

×

Caterpillar CAT 303.5 Mini Hydraulic Excavator Service Repair Manual (AFW00001 and up)

$65.00

Caterpillar CAT 303.5 Mini Hydraulic Excavator Service Repair Manual (AFW00001 and up)

$65.00

Case STX275, STX325, STX375, STX425, STX450, STX500 Steiger Tractor Service Manual

$45.00

Brand: Case

Models: STX275, STX325, STX375, STX425, STX450, STX500 Steiger

Type: Tractor

The service manual provides comprehensive guidance with 4167 and 3578 pages.

Publication Numbers: 6-14440 & 6-13290

Language: English

Format: PDF

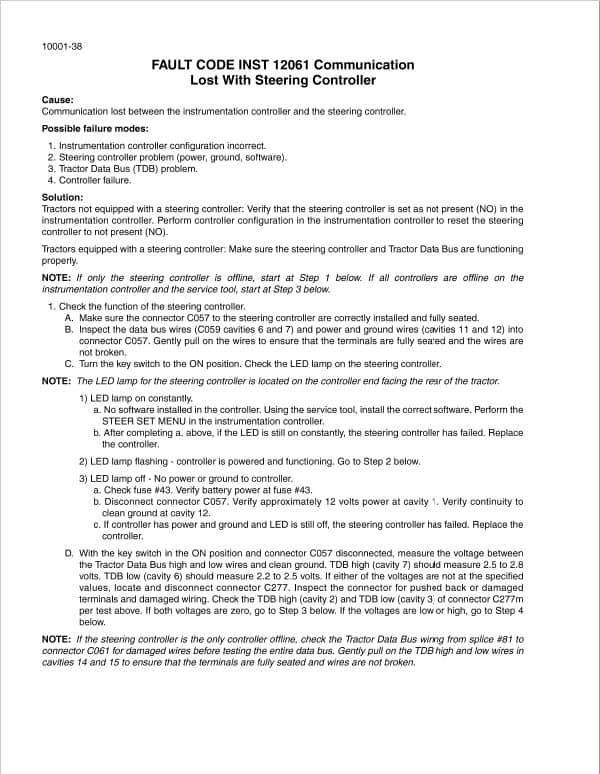

Instrumentation Programming Manual

Product Overview

This comprehensive manual provides detailed instructions for configuring and calibrating the standard instrumentation controller on tractors. Proper setup is crucial to ensure optimal functionality and compatibility across various tractor models and components.

Key Features

- Three-Level Programming: Ensures precise customization and compatibility.

- Initial Setup: Adjusts display units and tire radius for accurate readings.

- Controller Configuration: Allows viewing and configuration of electronic controllers expected on the TDB (Tractor Data Bus).

- Service Tool Compatibility: Essential for selecting tractor model and fuel tank size.

Benefits

- Ensures consistent performance across all tractor models.

- Facilitates seamless integration of replacement or new instrumentation controllers.

- Customizable settings provide flexibility in tractor operation.

Usage Recommendations

- Initial Setup: Perform the three-level programming whenever an instrumentation controller is transferred to a different tractor.

- Fuel Tank Configuration: When replacing the instrumentation controller, correctly select the fuel tank size using the service tool configuration window.

- Consult Manual Section: Refer to sections on General, Engine, Electrical, and more for specific configuration instructions.

Table of Contents

- General

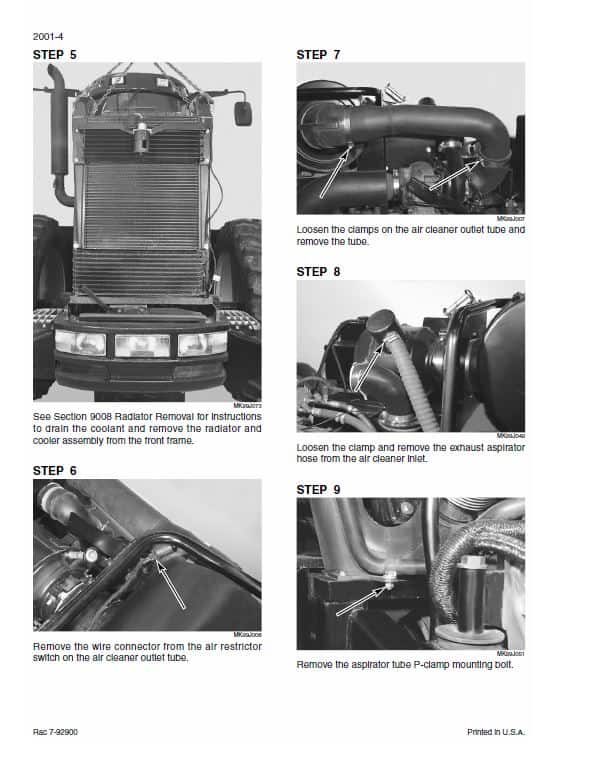

- Engine

- Electrical

- Steering

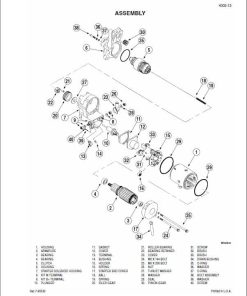

- Power Train

- Brakes

- Hydraulics

- Chassis

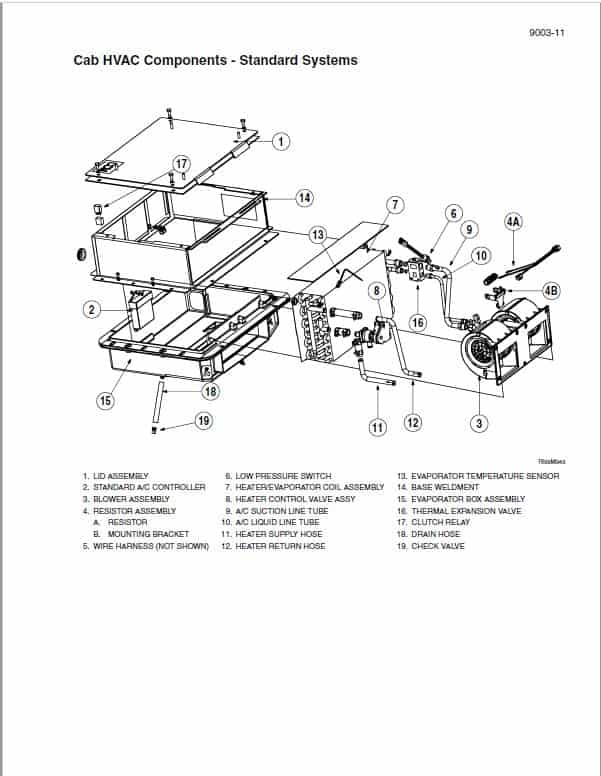

- Air Conditioning

- Controller Fault Codes

- Electrical Schematic

- Hydraulic Schematic

Please note the importance of following each programming level systematically to ensure compatibility and optimal performance of your tractor’s instrumentation system.

Only logged in customers who have purchased this product may leave a review.

Related products

$34.00

$34.50

$34.00

$35.00

$34.00

Reviews

There are no reviews yet.