-

×

SKODA OCTAVIA II (1Z, 91) Repair Service Manual

$45.00

SKODA OCTAVIA II (1Z, 91) Repair Service Manual

$45.00 -

×

SKODA KAROQ (NU) Repair Service Manual

$45.00

SKODA KAROQ (NU) Repair Service Manual

$45.00 -

×

SKODA FABIA III (NJ) Repair Service Manual

$41.00

SKODA FABIA III (NJ) Repair Service Manual

$41.00 -

×

SKODA SLAVIA (PB) Repair Service Manual

$45.00

SKODA SLAVIA (PB) Repair Service Manual

$45.00 -

×

SKODA FABIA (6Y) Repair Service Manual

$40.00

SKODA FABIA (6Y) Repair Service Manual

$40.00 -

×

SKODA SCALA (NW, NW1) Repair Service Manual

$41.00

SKODA SCALA (NW, NW1) Repair Service Manual

$41.00 -

×

SKODA YETI (5L, 67) Repair Service Manual

$46.00

SKODA YETI (5L, 67) Repair Service Manual

$46.00 -

×

Still Electric Forklift Truck RX60: Model RX60-40, RX60-45, RX60-50 Repair Manual

$34.00

Still Electric Forklift Truck RX60: Model RX60-40, RX60-45, RX60-50 Repair Manual

$34.00 -

×

SKODA OCTAVIA TOUR (1U) Repair Service Manual

$39.00

SKODA OCTAVIA TOUR (1U) Repair Service Manual

$39.00 -

×

Volvo PF161 Pipelayer Repair Service Manual

$21.00

Volvo PF161 Pipelayer Repair Service Manual

$21.00 -

×

Volvo PF3172 Pipelayer Repair Service Manual

$21.00

Volvo PF3172 Pipelayer Repair Service Manual

$21.00

Case SV208/SV210 Maintenance Manual

Product Overview

This comprehensive manual provides detailed instructions for the maintenance and servicing of the Case SV208 and SV210 models. It is essential for ensuring optimal performance and longevity of your machinery by guiding users through various mechanical procedures.

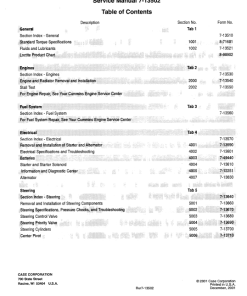

Table of Contents

- Introduction

- Engine

- Power Coupling

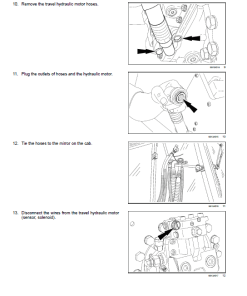

- Hydrostatic Drive

- Brakes and Controls

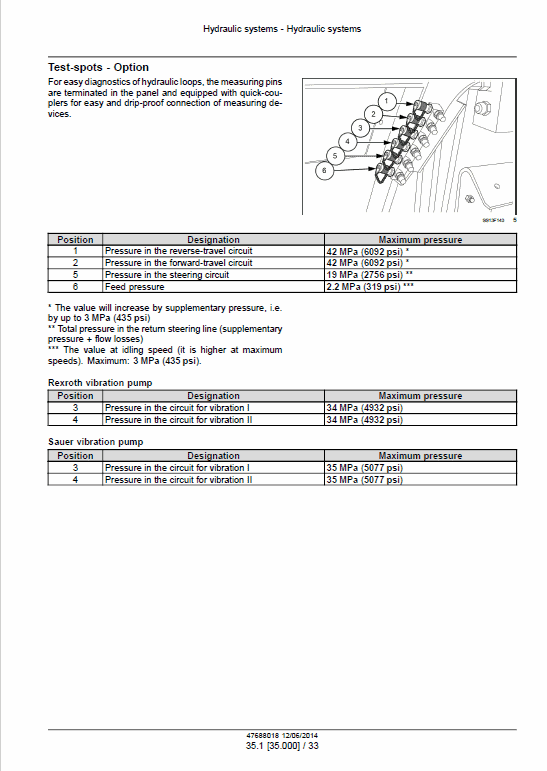

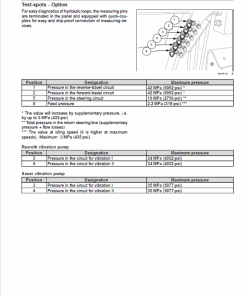

- Hydraulic System

- Frames and Ballasting

- Steering

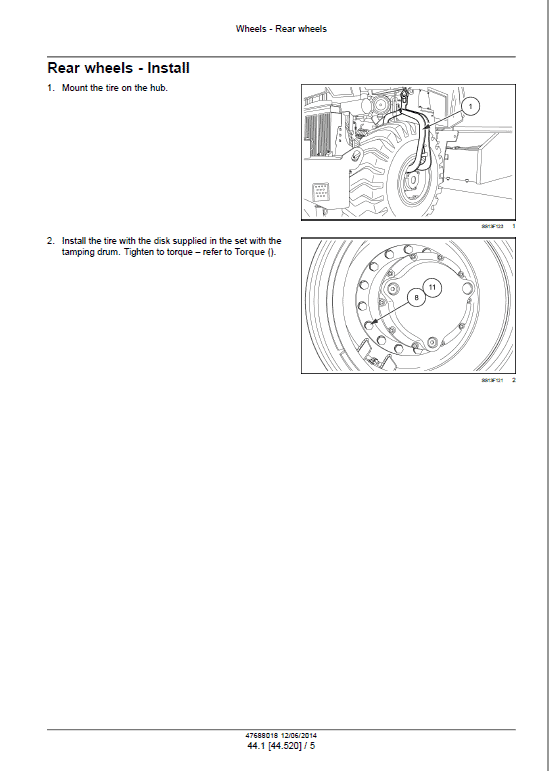

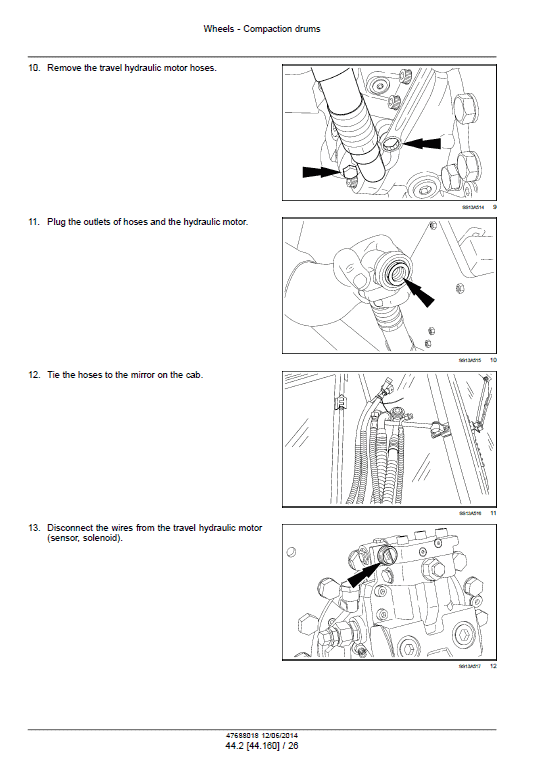

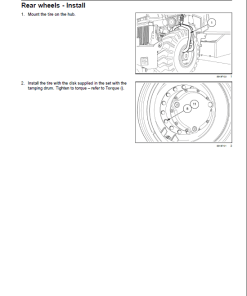

- Wheels

- Cab Climate Control

- Electrical System

Manual Extract: Compaction/Vibration Hydraulic System – Changing Fluid

This section of the manual provides step-by-step guidance on how to effectively change the hydraulic oil in your compaction and vibration system.

n

NOTICE: For optimal results, the oil should be changed after roller operation when impurities are diffused within the medium.

Steps to Change Hydraulic Oil

- Park the roller on a flat, paved area so the drain plug on the left-hand side of the drum is at its lowest point.

- Place a suitable container underneath the plug to catch the oil.

- Remove all plugs and drain the oil completely.

- Once the oil has drained, reinstall the drain plug securely.

- Use the filler hole to replenish the oil, filling until it reaches the edge of the inspection hole.

- Reinstall the remaining plugs to complete the process.

Benefits of Regular Maintenance

- Enhances the longevity and reliability of your machinery.

- Ensures the equipment operates at peak efficiency.

- Reduces the risk of unexpected breakdowns and associated costs.

Usage Recommendations

- Regularly review this manual to familiarize yourself with maintenance routines.

- Only use recommended oil types and follow guidelines for changing intervals.

- Conduct a thorough inspection of the machinery components during each service.

For further reference or to view the image guide, please follow this link.

Only logged in customers who have purchased this product may leave a review.

Related products

$34.00

$34.00

$34.00

$34.00

$33.50

$34.00

Reviews

There are no reviews yet.