Case SV208D Vibratory Roller Service Manual

$34.00

Enhance your maintenance capabilities with the comprehensive New Holland SV208D Roller Service Manual. This detailed guide spans 432 pages, offering essential information for effectively servicing your equipment.

Alternator Electrical System Manual

Product Overview

This comprehensive manual covers essential aspects of the alternator system and its integration within your machinery. Designed to provide clear guidance and ensure optimal performance, this resource is invaluable for operators and maintenance engineers.

Content Guide

- Content

- Introduction

- Maintenance

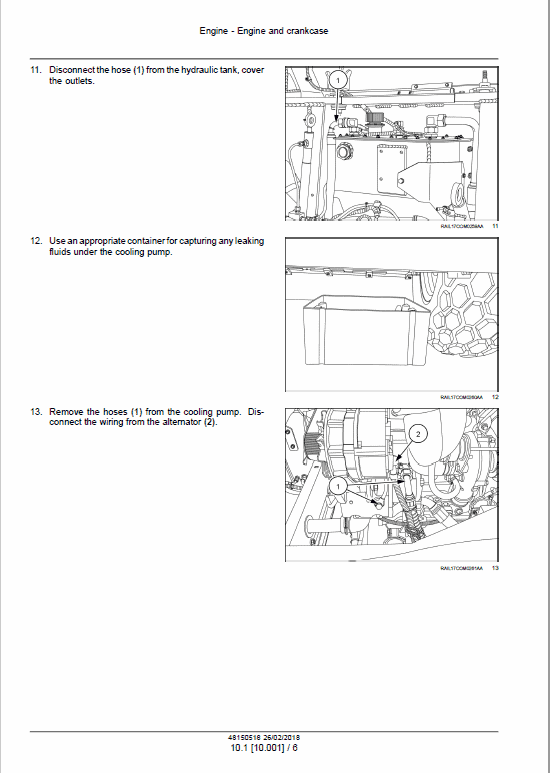

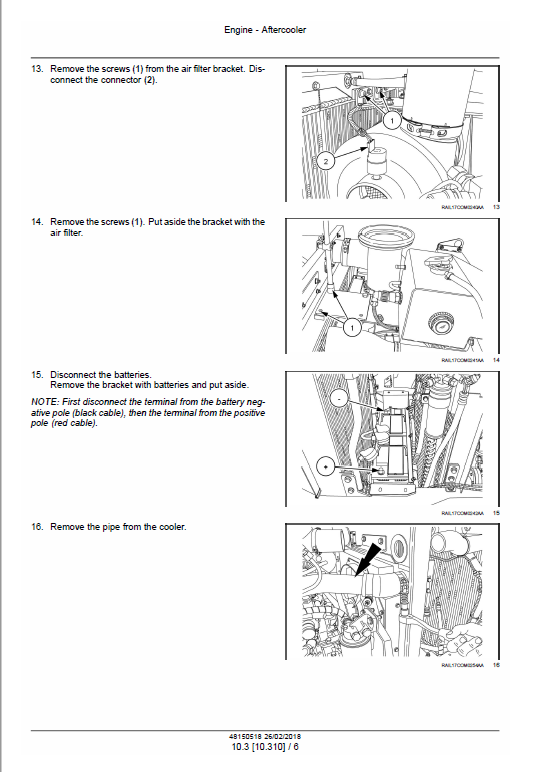

- Engine

- Hydrostatic Drive

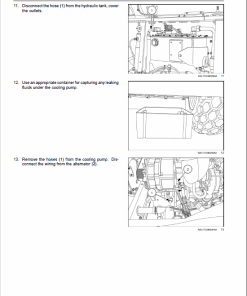

- Hydraulic System

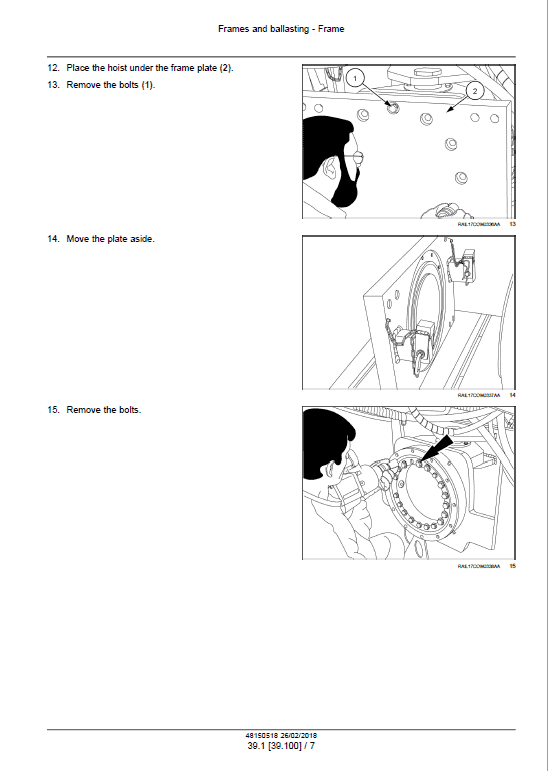

- Frames and Ballasting

- Steering

- Cab Climate Control

- Electrical System

- Platform, Cab, Bodywork, and Decals

- Special Index Tools

- Electrical Schematics

- Hydraulic Schematics

Key Features

- Source of Electrical Energy: The alternator is the central source of electrical power for the system.

- Voltage Regulation: Integrated semiconductor voltage regulator maintains stable output voltage under varying conditions.

- Proper Connection Required: Always connect the alternator to the battery, ensuring +B terminal connection.

Benefits

- Reliable Operation: Proper setup ensures the alternator operates seamlessly, reducing downtime and enhancing productivity.

- Safety Assurance: Following guidelines prevents electrical faults and potential hazards.

- Long Equipment Life: Regular maintenance and correct handling extend the lifespan of electrical components.

Usage Recommendations

- Avoid Short Circuits: Disconnect the alternator when repairing wiring or conducting welding operations.

- Battery Connection: Never disconnect the battery while the engine is running. External start sources should not be disconnected if the battery isn’t connected yet.

- Indicator Bulb Maintenance: Replace burnt-out charging indicator bulbs immediately to ensure alternator excitation functions correctly.

- Prevent Water Damage: Keep water away from alternator’s ventilation openings during cleaning.

- Welding Precautions: Disconnect alternator leads from +B and +D terminals before welding, and disconnect the battery when repairing other electrical devices.

Only logged in customers who have purchased this product may leave a review.

Related products

$32.00

$34.00

$34.00

$34.00

$34.00

$34.00

$33.00

SKODA FABIA IV (PJ) Repair Service Manual

SKODA FABIA IV (PJ) Repair Service Manual  SKODA OCTAVIA III (5E, NL, NR) Repair Service Manual

SKODA OCTAVIA III (5E, NL, NR) Repair Service Manual  SKODA KUSHAQ (PA) Repair Service Manual

SKODA KUSHAQ (PA) Repair Service Manual

Reviews

There are no reviews yet.