-

×

Caterpillar CAT 3512C Marine Engine Service Repair Manual (TKP00001 and up)

$50.00

Caterpillar CAT 3512C Marine Engine Service Repair Manual (TKP00001 and up)

$50.00 -

×

Caterpillar CAT 3516 Generator Set Engine Service Repair Manual (5SJ00001 and up)

$50.00

Caterpillar CAT 3516 Generator Set Engine Service Repair Manual (5SJ00001 and up)

$50.00 -

×

Still Engine VW 2.0i Turbo Diesel (CBHA, CBJB) Workshop Repair Manual

$26.00

Still Engine VW 2.0i Turbo Diesel (CBHA, CBJB) Workshop Repair Manual

$26.00 -

×

Caterpillar CAT 3508C Marine Engine Service Repair Manual (TTA00001 and up)

$50.00

Caterpillar CAT 3508C Marine Engine Service Repair Manual (TTA00001 and up)

$50.00 -

×

Caterpillar CAT 3160 Generator Set Engine Service Repair Manual (67P00001 and up)

$50.00

Caterpillar CAT 3160 Generator Set Engine Service Repair Manual (67P00001 and up)

$50.00 -

×

Caterpillar CAT 3508C Marine Engine Service Repair Manual (PXA00001 and up)

$50.00

Caterpillar CAT 3508C Marine Engine Service Repair Manual (PXA00001 and up)

$50.00 -

×

John Deere 870G, 870GP, 872G, 872GP Grader Technical Manual (S.N - 634753 )

$47.00

John Deere 870G, 870GP, 872G, 872GP Grader Technical Manual (S.N - 634753 )

$47.00 -

×

John Deere 1412E, 1810E, 1814E Scrapers Parts Catalog Manual - PC9130

$20.00

John Deere 1412E, 1810E, 1814E Scrapers Parts Catalog Manual - PC9130

$20.00 -

×

Caterpillar CAT 3126 Marine Engine Service Repair Manual (1ZJ00001 and up)

$45.00

Caterpillar CAT 3126 Marine Engine Service Repair Manual (1ZJ00001 and up)

$45.00 -

×

John Deere 27C ZTS, 35C ZTS Excavator Repair Technical Manual

$44.00

John Deere 27C ZTS, 35C ZTS Excavator Repair Technical Manual

$44.00 -

×

John Deere 870G, 870GP, 872G, 872GP Grader Technical Manual (S.N F678818 - F680877)

$52.00

John Deere 870G, 870GP, 872G, 872GP Grader Technical Manual (S.N F678818 - F680877)

$52.00 -

×

Caterpillar CAT 3126 Reman Engine Service Repair Manual (6RW00001 and up)

$50.00

Caterpillar CAT 3126 Reman Engine Service Repair Manual (6RW00001 and up)

$50.00 -

×

John Deere 670G, 670GP, 672G, 672GP Grader Technical Manual (SN - 634753)

$52.00

John Deere 670G, 670GP, 672G, 672GP Grader Technical Manual (SN - 634753)

$52.00 -

×

John Deere 1170G Forwarders (SN F003107-) Parts Catalog Manual - PC13564

$80.00

John Deere 1170G Forwarders (SN F003107-) Parts Catalog Manual - PC13564

$80.00 -

×

Caterpillar CAT 3304 Engine Machine Service Repair Manual (09Z00001 and up)

$50.00

Caterpillar CAT 3304 Engine Machine Service Repair Manual (09Z00001 and up)

$50.00

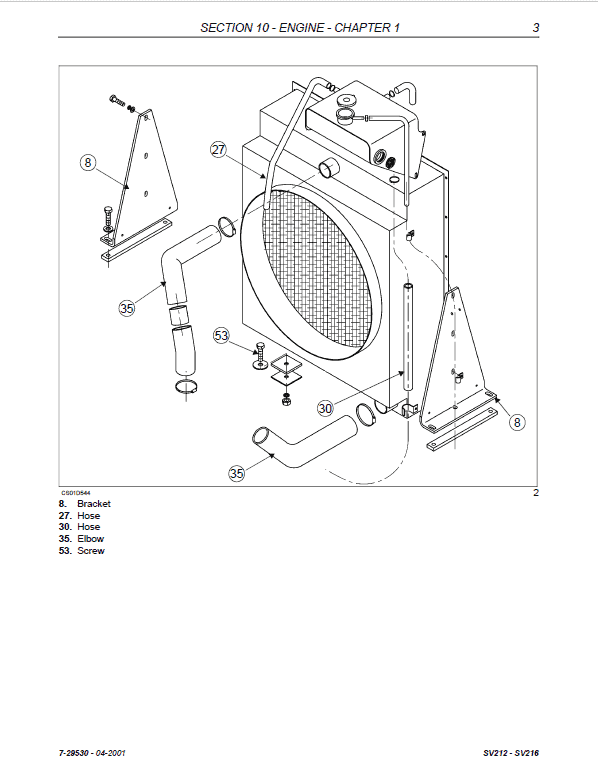

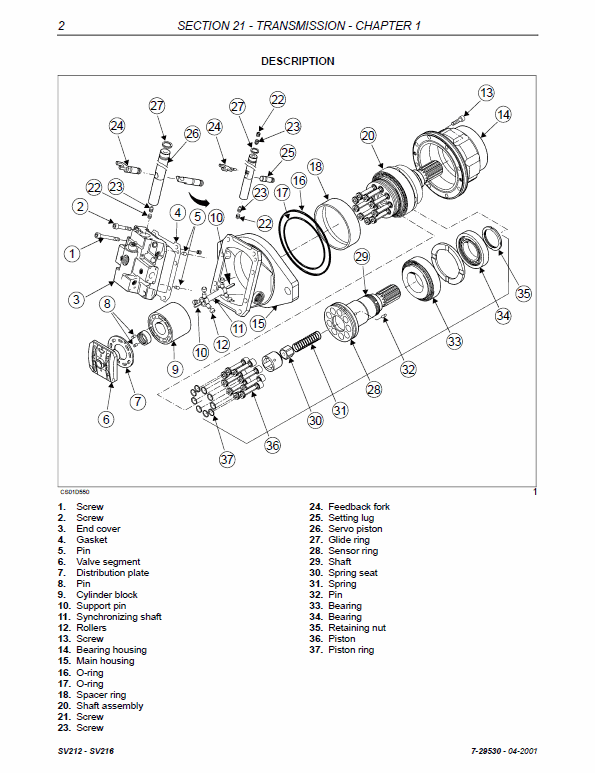

Hydraulic System Overview for SV212 and SV216 Machines

Product Overview

The hydraulic system is a critical component that manages the primary functions of the SV212 and SV216 machines. It converts hydraulic energy into kinetic energy to ensure smooth operation across various machine systems. This is achieved via hydraulic pumps, motors, pipes, pressure hoses, and several control and safety mechanisms.

Key Features

- Electro valves, safety and control valves, and hydrostatic locks for optimal regulation.

- Separate circuits for travel, vibration, control, and lifting operations.

- Efficient hydraulic distribution through a well-designed network of piping and hoses.

Benefits

- A reliable hydraulic system that enhances the functionality and safety of the machines.

- Customizable settings for optimal performance tailored to specific tasks.

- Seamless integration between different machine components to deliver superior performance.

Usage Recommendations

- Regularly check the hydraulic fluid levels in the reservoir for consistent performance.

- Conduct periodic maintenance of valves and regulators for smooth operation.

- Adjust the control pressure by-pass valve to suit machine-specific requirements: set to 42 bar (609 psi) for SV212 and 28 bar (406 psi) for SV216.

- Ensure consistent 22 bar (319 psi) pressure setting in the travel pump bodies for both machines.

Diagram Insights

Both the SV212 and SV216 machines have similar hydraulic circuit connections with differences primarily in pump and motor types:

- SV212: Uses a 90r042 pump and 90m042 hydraulic motor for vibration management.

- SV216: Utilizes a 90r055 pump and 90m055 hydraulic motor for enhanced vibration control.

For more detailed explanations on the operation of individual circuits or their components, please refer to the subsequent sections of the manual.

Only logged in customers who have purchased this product may leave a review.

Related products

$34.00

$33.00

$33.00

$33.00

$34.00

$34.00

Reviews

There are no reviews yet.