-

×

Caterpillar CAT 160K Motor Grader Service Repair Manual (JBP00001 and up)

$75.00

Caterpillar CAT 160K Motor Grader Service Repair Manual (JBP00001 and up)

$75.00 -

×

Tigercat 215 Loader Operator Manual (2150101 - 2151000)

$24.00

Tigercat 215 Loader Operator Manual (2150101 - 2151000)

$24.00 -

×

Caterpillar CAT 160H Motor Grader Service Repair Manual (9EJ00001 and up)

$70.00

Caterpillar CAT 160H Motor Grader Service Repair Manual (9EJ00001 and up)

$70.00 -

×

Caterpillar CAT 140M 2 Motor Grader Service Repair Manual (M9J00001 and up)

$70.00

Caterpillar CAT 140M 2 Motor Grader Service Repair Manual (M9J00001 and up)

$70.00 -

×

JCB TM200, TM270, TM300 Wheeled Loader Shovel Service Manual

$34.00

JCB TM200, TM270, TM300 Wheeled Loader Shovel Service Manual

$34.00 -

×

Caterpillar CAT 16G Motor Grader Service Repair Manual (93U02679 and up)

$80.00

Caterpillar CAT 16G Motor Grader Service Repair Manual (93U02679 and up)

$80.00 -

×

Caterpillar CAT 150 Motor Grader Service Repair Manual (ENK00001 and up)

$80.00

Caterpillar CAT 150 Motor Grader Service Repair Manual (ENK00001 and up)

$80.00 -

×

Bobcat T40140, T40170, T40180 Telescopic Handler Service Repair Manual

$40.00

Bobcat T40140, T40170, T40180 Telescopic Handler Service Repair Manual

$40.00 -

×

Caterpillar CAT 140G Motor Grader Service Repair Manual (81V01031 and up)

$70.00

Caterpillar CAT 140G Motor Grader Service Repair Manual (81V01031 and up)

$70.00 -

×

JCB 426, 435, 436, 446 Wheeled Loader Shovel Service Manual

$36.00

JCB 426, 435, 436, 446 Wheeled Loader Shovel Service Manual

$36.00 -

×

Bobcat TR40250 EVO, TR50190 EVO, TR50210 EVO versaHandler Telescopic Service Repair Manual

$36.00

Bobcat TR40250 EVO, TR50190 EVO, TR50210 EVO versaHandler Telescopic Service Repair Manual

$36.00

Comprehensive Guide for Machinery Maintenance

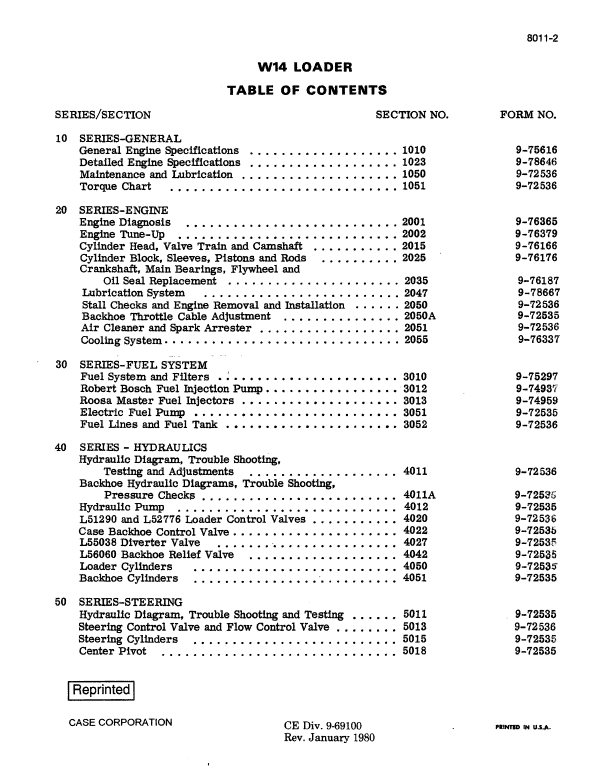

Table of Contents

- General

- Engines

- Fuel System

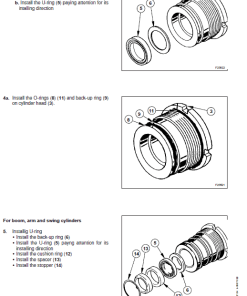

- Hydraulics

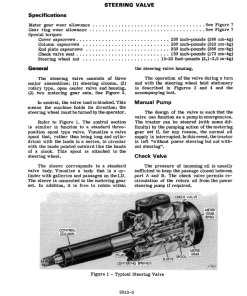

- Steering

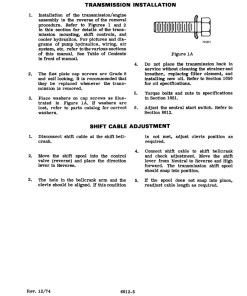

- Power Train

- Brakes

- Electrical

- Mounted Equipment

Manual Extract: Valve Lift Adjustment

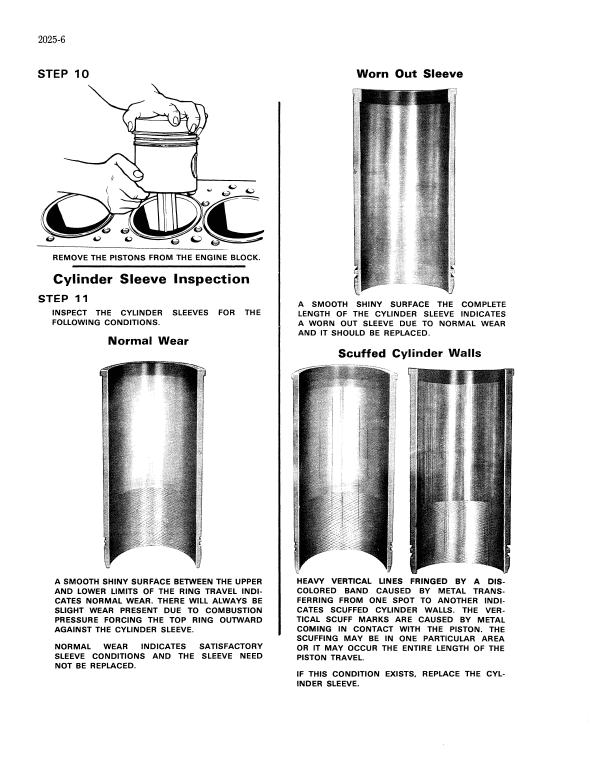

Properly adjusting the valve lift is critical for the optimal performance of machinery. Follow these detailed steps to ensure precise adjustment:

Steps to Set Valve Lift

-

While pumping fuel through the injector, maintain a hold on the pressure adjusting screw. Gradually turn the lift adjusting screw clockwise until the valve stops opening.

Note: Depending on the injector model, the lift adjusting screw may have either a screwdriver slot or an Allen wrench slot. - Increase the pressure by 200 to 500 PSI above the injector’s opening pressure to verify valve bottoming. It’s normal for some fuel to accumulate at the tip, but there should be no rapid dribble. Do not use excessive force to avoid bending the valve.

- Rotate the lift adjusting screw counterclockwise for 3/4 of a turn to achieve the specified lift. While holding the lift adjusting screw, secure it by tightening the locknut to 35 to 45 inch-pounds. Utilize the Snap-On Tool 1/4″ Crow’s-foot Wrench No. AN 9508-6 and a suitable inch-pound torque wrench.

- Reassess the opening pressure. Remember that setting the lift is crucial before inspecting the spray pattern and chatter, as the lift adjustment influences these characteristics.

Only logged in customers who have purchased this product may leave a review.

Related products

$33.50

$34.00

$34.50

$35.00

$33.00

$32.00

$34.00

Reviews

There are no reviews yet.