-

×

Bobcat 2000 Loader Service Manual

$32.00

Bobcat 2000 Loader Service Manual

$32.00 -

×

Bobcat T250 Loader Service Manual

$35.00

Bobcat T250 Loader Service Manual

$35.00 -

×

Bobcat T770 Loader Service Manual

$36.00

Bobcat T770 Loader Service Manual

$36.00 -

×

Tigercat 250B Loader Repair Service Manual (2500501 - 2502000)

$34.00

Tigercat 250B Loader Repair Service Manual (2500501 - 2502000)

$34.00 -

×

Cummins ISB and QSB5.9 Engines Shop Service Manual

$25.00

Cummins ISB and QSB5.9 Engines Shop Service Manual

$25.00 -

×

Bobcat T250 Turbo and Turbo High Flow Track Loader Service Manual

$35.00

Bobcat T250 Turbo and Turbo High Flow Track Loader Service Manual

$35.00 -

×

Tigercat 2160 Loader Forwarder Repair Service Manual (21600101 - 21600500)

$40.00

Tigercat 2160 Loader Forwarder Repair Service Manual (21600101 - 21600500)

$40.00 -

×

AGCO Sisu Power 33, 44, 49, 66, 74, 84,98 (4th Generation) Engine Manual

$24.00

AGCO Sisu Power 33, 44, 49, 66, 74, 84,98 (4th Generation) Engine Manual

$24.00 -

×

Tigercat 234B Loader Repair Service Manual

$40.00

Tigercat 234B Loader Repair Service Manual

$40.00 -

×

Cummins ISB, ISC, ISL, ISLe, ISDe, and QSB3.3 Engines Repair Manual

$37.00

Cummins ISB, ISC, ISL, ISLe, ISDe, and QSB3.3 Engines Repair Manual

$37.00 -

×

Bobcat B700 Loader Service Repair Manual

$38.00

Bobcat B700 Loader Service Repair Manual

$38.00 -

×

Bobcat 2400 Loader Service Manual

$35.00

Bobcat 2400 Loader Service Manual

$35.00 -

×

Bobcat BL370 (B-Series) Loader Service Repair Manual

$38.00

Bobcat BL370 (B-Series) Loader Service Repair Manual

$38.00 -

×

JCB SD70, SD80 Steer Drive Axles Service Repair Manual

$21.00

JCB SD70, SD80 Steer Drive Axles Service Repair Manual

$21.00 -

×

Bobcat T450 Compact Track Loader Service Repair Manual

$36.00

Bobcat T450 Compact Track Loader Service Repair Manual

$36.00 -

×

Bobcat B780 Loader Service Repair Manual

$38.00

Bobcat B780 Loader Service Repair Manual

$38.00 -

×

Kohler Diesel KDI 1903 TCR and KDI 2504 TCR Engine Service Repair Manual

$26.00

Kohler Diesel KDI 1903 TCR and KDI 2504 TCR Engine Service Repair Manual

$26.00 -

×

Tigercat T234B Loader Repair Service Manual (234T7000 - 234T8100)

$37.00

Tigercat T234B Loader Repair Service Manual (234T7000 - 234T8100)

$37.00 -

×

Sisudielsel 320, 420, 620, 634 Engines Workshop Service Manual

$25.00

Sisudielsel 320, 420, 620, 634 Engines Workshop Service Manual

$25.00 -

×

Bobcat BL470, BL475 Loader Service Repair Manual

$38.00

Bobcat BL470, BL475 Loader Service Repair Manual

$38.00 -

×

Bobcat T650 Loader Repair Service Manual

$35.00

Bobcat T650 Loader Repair Service Manual

$35.00 -

×

Tigercat 250 Loader Repair Service Manual (2500101 - 2500499)

$34.00

Tigercat 250 Loader Repair Service Manual (2500101 - 2500499)

$34.00 -

×

Bobcat T750 Loader Service Manual

$36.00

Bobcat T750 Loader Service Manual

$36.00 -

×

Kohler Diesel KDI 1903 M and KDI 2504 M Engine Service Manual

$25.00

Kohler Diesel KDI 1903 M and KDI 2504 M Engine Service Manual

$25.00 -

×

Scania DC16, DI16 16-litre Engine Workshop Service Manual

$25.00

Scania DC16, DI16 16-litre Engine Workshop Service Manual

$25.00 -

×

Timberjack 933D Clambunk Service Repair Manual (933191 and up)

$39.00

Timberjack 933D Clambunk Service Repair Manual (933191 and up)

$39.00 -

×

Bobcat T320 Loader Service Manual

$35.00

Bobcat T320 Loader Service Manual

$35.00 -

×

JCB AGCO OEM Transmission ML180 T702 Manual

$30.00

JCB AGCO OEM Transmission ML180 T702 Manual

$30.00 -

×

John Deere 2954D Road Builder Repair Technical Manual (TM10406)

$34.00

John Deere 2954D Road Builder Repair Technical Manual (TM10406)

$34.00 -

×

Timberjack 608 Carriers Service Repair Manual (977031 - 987326)

$39.00

Timberjack 608 Carriers Service Repair Manual (977031 - 987326)

$39.00 -

×

Peerless 2170B, 2770 Loader Service Repair Manual (CB1066-CE1313, 961314 and Up)

$35.00

Peerless 2170B, 2770 Loader Service Repair Manual (CB1066-CE1313, 961314 and Up)

$35.00 -

×

Timberjack 530B Log Loader Service Repair Manual

$39.00

Timberjack 530B Log Loader Service Repair Manual

$39.00 -

×

Timberjack 608 Carriers Service Repair Manual (977031 - 987326)

$38.00

Timberjack 608 Carriers Service Repair Manual (977031 - 987326)

$38.00 -

×

John Deere 3554 Logger Repair Technical Manual - (TM2106)

$29.00

John Deere 3554 Logger Repair Technical Manual - (TM2106)

$29.00 -

×

John Deere 335C Knuckleboom Log Loader Repair Technical Manual - (TM2293)

$39.00

John Deere 335C Knuckleboom Log Loader Repair Technical Manual - (TM2293)

$39.00 -

×

Timberjack 610 Forwarder Service Repair Manual

$38.00

Timberjack 610 Forwarder Service Repair Manual

$38.00 -

×

Timberjack C90 Series Delimber Service Repair Manual

$38.00

Timberjack C90 Series Delimber Service Repair Manual

$38.00 -

×

John Deere 473C Knuckleboom Log Loader Repair Technical Manual - (TM2299)

$39.00

John Deere 473C Knuckleboom Log Loader Repair Technical Manual - (TM2299)

$39.00 -

×

Timberjack 122, 130 Grapple Service Repair Manual

$25.00

Timberjack 122, 130 Grapple Service Repair Manual

$25.00 -

×

John Deere 1458 Forwarder Repair Technical Manual (TM1993)

$35.00

John Deere 1458 Forwarder Repair Technical Manual (TM1993)

$35.00 -

×

Timberjack 608B Carriers Service Repair Manual (987327 and Up)

$39.00

Timberjack 608B Carriers Service Repair Manual (987327 and Up)

$39.00 -

×

John Deere Timberjack TMC Control System Operators and Repair Manual

$28.00

John Deere Timberjack TMC Control System Operators and Repair Manual

$28.00 -

×

Timberjack 1010 Forwarder Service Repair Manual (10101657 and Up)

$29.00

Timberjack 1010 Forwarder Service Repair Manual (10101657 and Up)

$29.00 -

×

Timberjack 1710 Forwarder Service Repair Manual (17100090 and Up)

$39.00

Timberjack 1710 Forwarder Service Repair Manual (17100090 and Up)

$39.00 -

×

John Deere 1758 Forwarder Repair Technical Manual (TM1995)

$35.00

John Deere 1758 Forwarder Repair Technical Manual (TM1995)

$35.00 -

×

Timberjack 1210 Forwarder Service Repair Manual (12100218 and Up)

$28.00

Timberjack 1210 Forwarder Service Repair Manual (12100218 and Up)

$28.00 -

×

Timberjack 810B Forwarder Service Repair Manual (17DA0906 and Up)

$39.00

Timberjack 810B Forwarder Service Repair Manual (17DA0906 and Up)

$39.00 -

×

Timberjack 330, 430 Knuckle Boom Loader Service Repair Manual

$35.00

Timberjack 330, 430 Knuckle Boom Loader Service Repair Manual

$35.00 -

×

John Deere 335, 435 Log Loader Repair Technical Manual (TM1875)

$35.00

John Deere 335, 435 Log Loader Repair Technical Manual (TM1875)

$35.00

Water Pump Maintenance Manual

Product Overview

This comprehensive manual provides detailed instructions on inspecting and maintaining the water pump of your machinery. It covers various components and offers insights on the replacement of parts to ensure optimal performance.

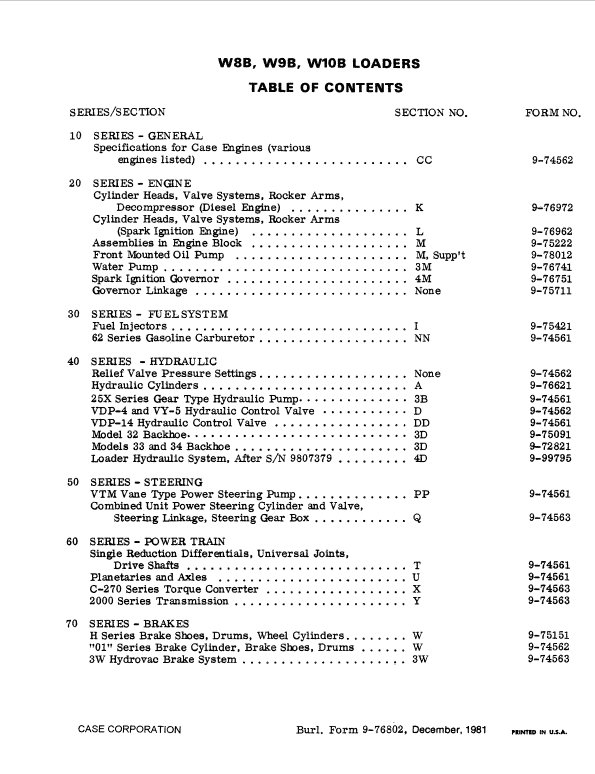

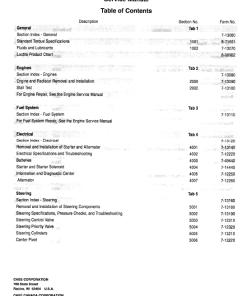

Table of Contents

- General

- Engines

- Fuel System

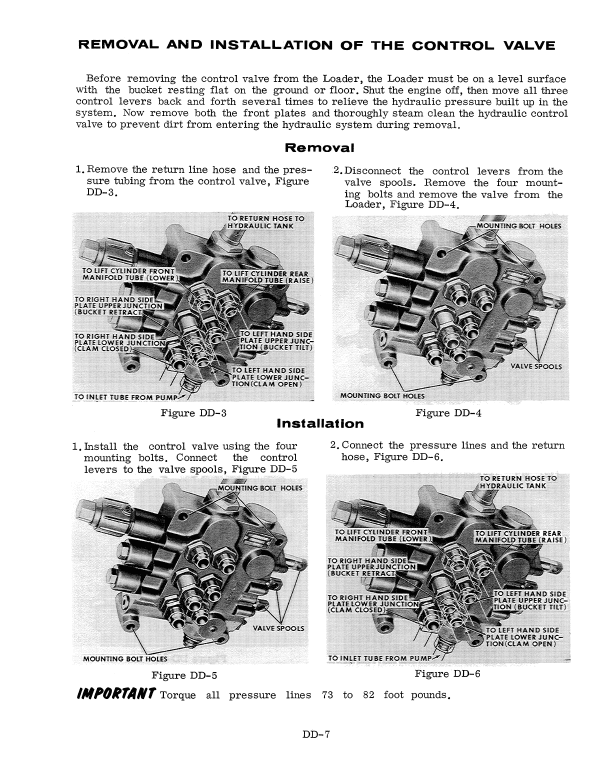

- Hydraulics

- Steering

- Power Train

- Brakes

- Electrical

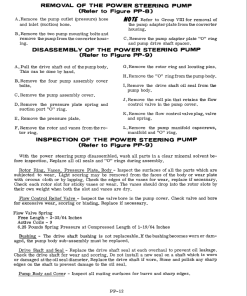

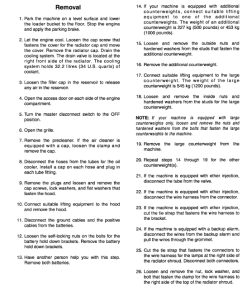

Manual Extract: Water Pump Inspection

Ensure the longevity and efficiency of your water pump with careful inspection during maintenance. Follow these key steps:

Key Features

- Thorough Cleaning: With the water pump completely disassembled, every component should be cleaned and checked for wear, cracks, and burrs.

- Component Inspection: Inspect all parts carefully and replace any that show signs of wear or damage.

Benefits

- Enhanced Performance: Regular inspection and maintenance can prevent failures and extend the life of your water pump.

- Safety Assurance: Identifying and replacing worn components reduces the risk of mechanical failure.

Usage Recommendations

- Ball Bearings: Inspect for any nicks, burrs, or grooves that may lead to binding or wear. Replace if damaged.

- Pump Seal: Always replace the pump seal whenever the water pump is disassembled.

- Bushing: If equipped, check for wear, nicks, grooves, and burrs. Ensure the inside diameter is between .874″ and .875″ with a clearance of .0015″ to .004″ between the bushing and shaft.

- Pump Shaft: Look for nicks, grooves, and burrs. The diameter at the bushing contact point should be .8710″ to .8725″. Replace if any damage is found.

- Impeller: Examine for cracks, damaged vanes, and smoothness at the seal contact area and replace if necessary.

Note: Pumps with two bearings have a seat in the impeller (part 13) where the shaft seal resides, which is replaceable if needed.

Only logged in customers who have purchased this product may leave a review.

Related products

$34.00

$34.00

$33.50

$35.00

$34.00

$34.00

Reviews

There are no reviews yet.