Challenger MT225B Tractor Service Manual

$34.00

Pages: 226 & 246

Format: PDF

Book Numbers: 79024234 & 79024230

Language: English

Publication Date: November 2006

Challenger MT225B Tractor Repair Workshop Manual

Product Overview

The AGCO Challenger MT225B Series Tractor Repair Workshop Manual is an essential resource for anyone involved in the maintenance and repair of the MT225B Series tractors. Available in PDF format, this comprehensive manual is written in English and was first issued in November 2006. It covers both the hydrostatic and standard compact tractors in this series, with detailed guidance over 226 and 246 pages, respectively.

Key Features

- Format: PDF for easy access and use.

- Book Numbers: 79024234 & 79024230.

- Comprehensive coverage of both hydrostatic and standard compact models.

- Detailed assembly instructions and precautions to ensure proper maintenance.

Benefits

- Provides step-by-step guidance to facilitate accurate repairs.

- Helps reduce downtime by ensuring efficient servicing.

- Improves tractor performance with properly executed maintenance.

Usage Recommendations

- Ideal for mechanics, technicians, and tractor owners who need a deeper understanding of the MT225B Series.

- Recommended for use in workshops as a reliable reference during repair and maintenance.

Manual Table of Contents

- General Information

- Splitting the Tractor

- Engine

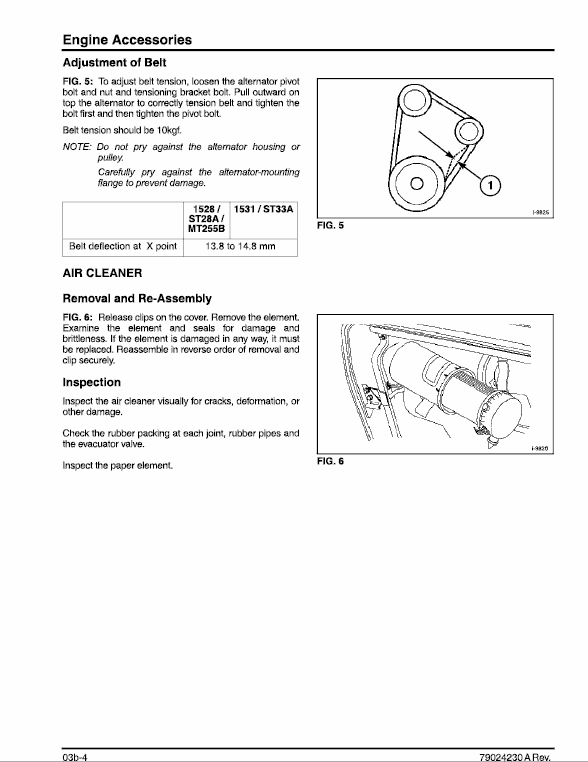

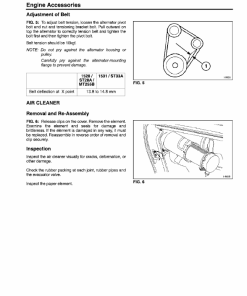

- Engine Accessories

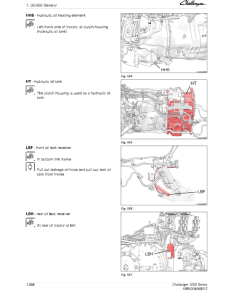

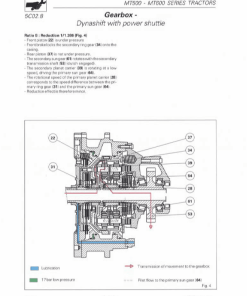

- Transmission

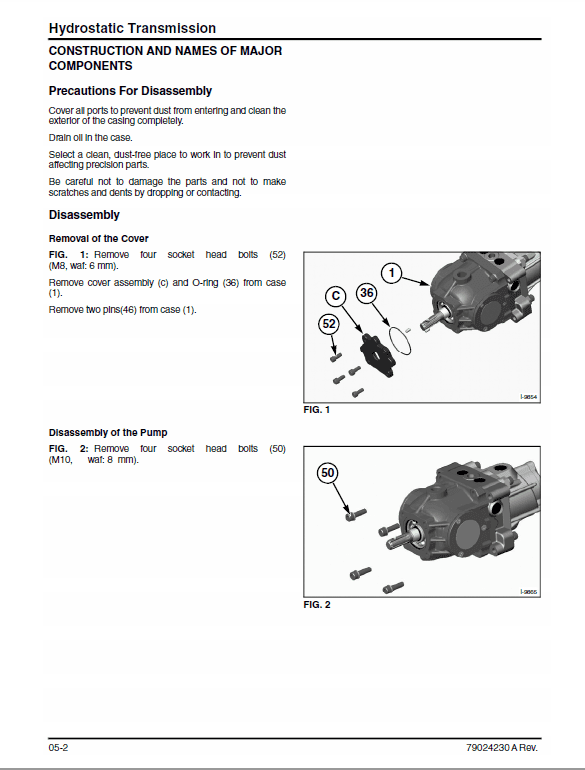

- Hydrostatic Transmission

- Rear Axle

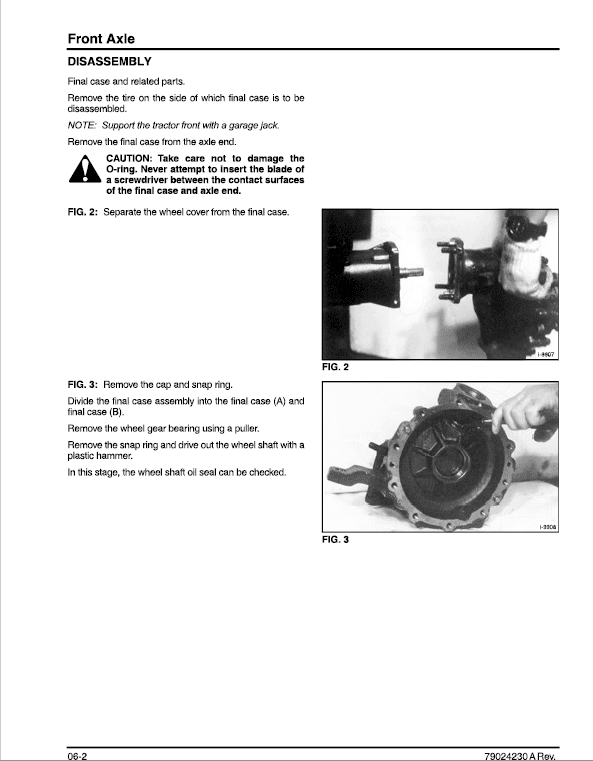

- Front Axle

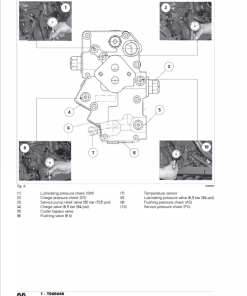

- Hydraulic System

- Electrical Accessories

- Steering System

Manual Extract: Precautions for Reassembly

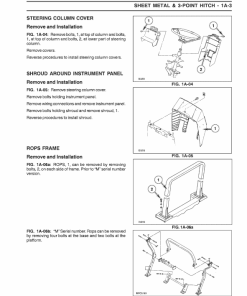

When reassembling parts, ensure the correct installation direction of gears, collars, and other components. Always install bearings and collars as specified. Some critical assembly steps include:

- Install the 4WD gear with the recessed side facing the bearing and the range shift gear on the drive pinion. See Fig. 14 for reference.

- Sub-assemble range shift gears and counter gear before inserting into the rear transmission case.

- Reinstall the PTO shaft joint coupling if it fell during disassembly.

- Install related shifters and levers appropriately.

- Ensure proper installation of all main gears and related parts.

After assembly, verify that each shift lever operates smoothly and check for correct operating load.

Only logged in customers who have purchased this product may leave a review.

Related products

Challenger

Reviews

There are no reviews yet.