Challenger MT485D, MT495D Tractor Service Manual

$40.00

Explore the comprehensive Challenger MT485D, MT495D Tractor Workshop Manual with detailed service information and technical guidance. This extensive manual spans 3,627 pages and includes essential documents for maintenance and repairs:

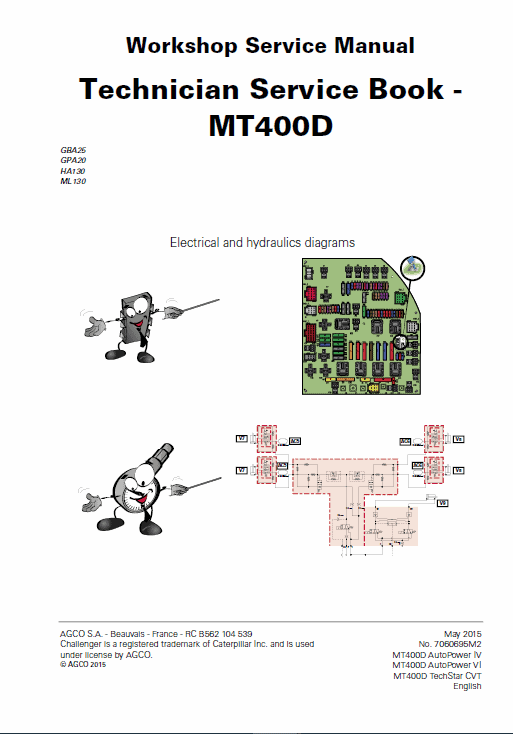

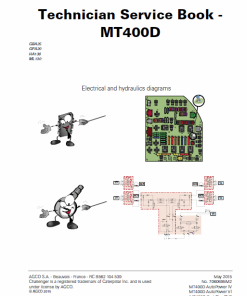

- Technician Service Book for MT400D – 683 pages

- Parts Catalog – 359 pages

- AGCO Sisu Engine Manual – 116 pages

For more information, visit the official Challenger website.

Challenger MT485D, MT495D Tractor Repair Workshop Manual

Product Overview

The AGCO Challenger MT400D Series Tractor Repair Workshop Manual is an essential resource for troubleshooting and servicing the MT485D and MT495D models. This comprehensive guide is formatted as a PDF and contains a detailed breakdown of components, instructions, and illustrations designed to enhance the efficiency of your maintenance tasks.

Details:

Format: PDF

Publication Number: 7060336M1

Language: English

Issued: April 2013

Total Pages: 3627

Key Features

- Comprehensive Technician Service Book – 683 Pages

- Detailed Parts Catalog – 359 Pages

- AGCO Sisu Engine Manual – 116 Pages

Benefits

- Provides in-depth technical guidance for effective servicing and repair.

- Enhances understanding of the tractor’s components and systems.

- Facilitates identification and procurement of spare parts with the parts catalog.

Usage Recommendations

- Ideal for technicians and service professionals who require detailed insight into the MT400D series.

- Useful for owners looking to perform routine maintenance and minor repairs.

- Essential for workshops handling the Challenger MT485D, MT495D models.

Manual Table of Contents

- Introduction

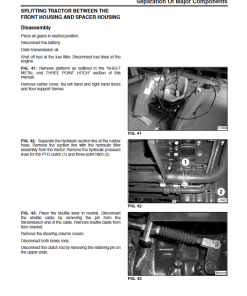

- Separating of Assemblies

- Engine

- Clutch

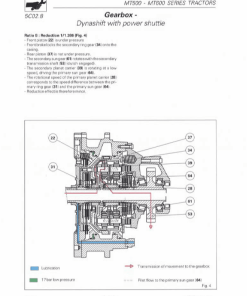

- Gearbox

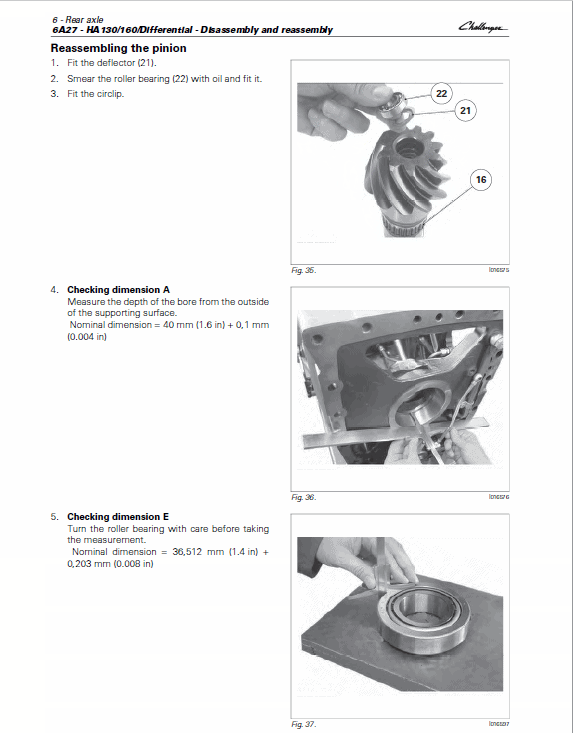

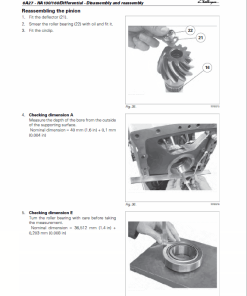

- Rear Axle

- Power Take Off

- Front Axle

- Electronics

- Accessories

- Service Tools

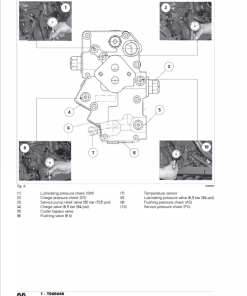

Component Overview

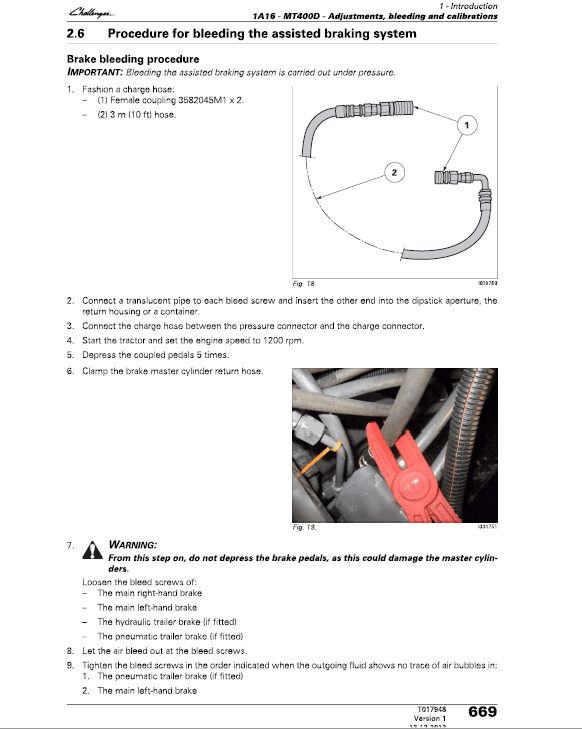

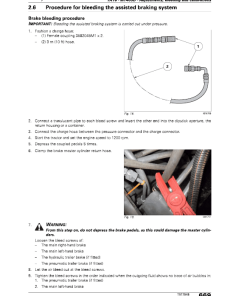

- Compressor: Connected to the engine lubrication system, filtering air through the engine air filter. Driven by the engine belt.

- Antifreeze Pump: Utilizes an alcohol-based antifreeze system to prevent freezing.

- Air Regulation: Pressure is regulated between 6.5 bar (94 psi) and 8 bar (116 psi) with a safety valve opening at 12 bar (174 psi).

- Tanks: Two tanks located around the rear axle, each with a 10-liter capacity and equipped with pressure sensors.

- Automatic Bleeding: Devices located under each tank for draining water in the system.

- Control Valve: Managed by the hydraulic and mechanical components of the braking system, activating air supply to the pneumatic line when needed.

- Pressure Sensor: Mounted on a tank, providing pressure data to the instrument panel. Alerts are triggered if pressure falls below 4 bar (58 psi).

- Couplers:

- Yellow: Connects the trailer’s main service brake line.

- Red: Provides a constant air supply, should be connected after the yellow and disconnected first.

Only logged in customers who have purchased this product may leave a review.

Related products

Challenger

Challenger

Reviews

There are no reviews yet.