Challenger MT515D, MT525D, MT535D, MT545D Tractor Workshop Manual

$50.00

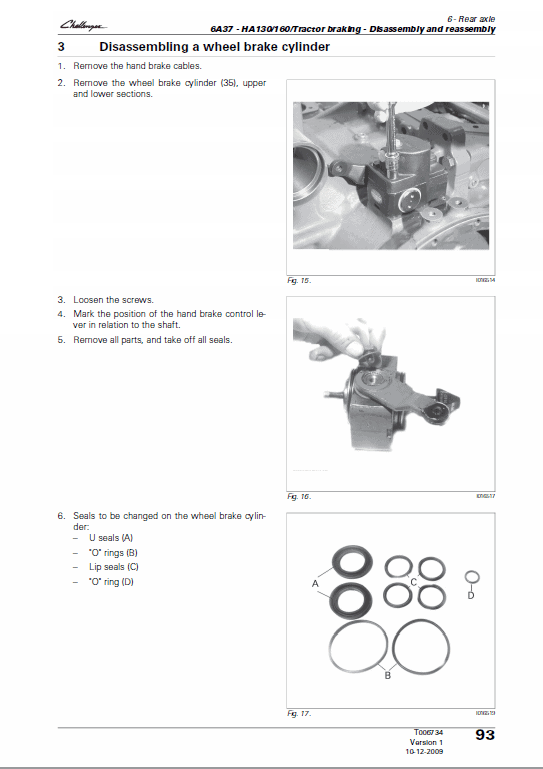

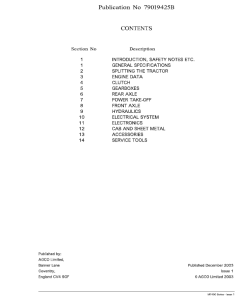

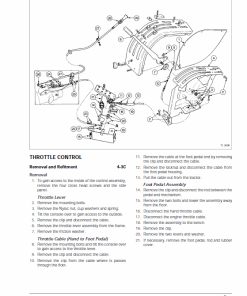

Challenger MT515D, MT525D, MT535D, MT545D Workshop Manual: A comprehensive 4226-page guide for detailed tractor maintenance and repairs.

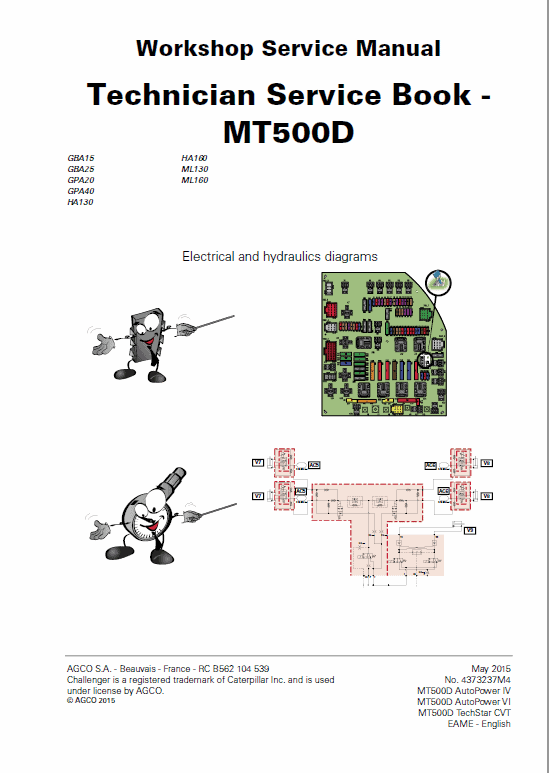

Technician Service Book MT500D: This 763-page manual covers schematics and electronics for the MT500D series tractors.

Parts Catalog TechStar CVT and AutoPower VI: Provides part details in two volumes with 594 and 466 pages respectively, ensuring efficient maintenance and repairs.

Maintenance Manual MT515D, MT525D, MT535D, MT545D: A concise 196-page manual outlining essential maintenance procedures for these models.

Spicer Dana Axle 735, 740, 750, 755 Axle Service Manual: A 176-page guide focusing on servicing these specific axle models, ensuring peak performance.

Reviews

There are no reviews yet.