-

×

Volvo EC140E L Excavator Repair Service Manual

$70.00

Volvo EC140E L Excavator Repair Service Manual

$70.00 -

×

Volvo DD105 Asphalt Compactors Repair Service Manual

$46.00

Volvo DD105 Asphalt Compactors Repair Service Manual

$46.00 -

×

Volvo G780 VHP Motor Grader Repair Service Manual

$55.00

Volvo G780 VHP Motor Grader Repair Service Manual

$55.00 -

×

Volvo ECR88 Compact Excavator Repair Service Manual

$50.00

Volvo ECR88 Compact Excavator Repair Service Manual

$50.00 -

×

Volvo A35F FS Articulated Dump Truck Repair Service Manual (SN 10001-99999)

$65.00

Volvo A35F FS Articulated Dump Truck Repair Service Manual (SN 10001-99999)

$65.00 -

×

Volvo EC60E Compact Excavator Repair Service Manual

$55.00

Volvo EC60E Compact Excavator Repair Service Manual

$55.00 -

×

Volvo G970 Motor Grader Repair Service Manual

$50.00

Volvo G970 Motor Grader Repair Service Manual

$50.00 -

×

Doosan DX350LC Excavator Service Manual

$34.00

Doosan DX350LC Excavator Service Manual

$34.00 -

×

Volvo A25B BM Articulated Dump Truck Repair Service Manual

$37.00

Volvo A25B BM Articulated Dump Truck Repair Service Manual

$37.00 -

×

Volvo EW200E MH Excavator Repair Service Manual

$55.00

Volvo EW200E MH Excavator Repair Service Manual

$55.00 -

×

Volvo EW180B Excavator Repair Service Manual

$50.00

Volvo EW180B Excavator Repair Service Manual

$50.00 -

×

Volvo EC60C Compact Excavator Repair Service Manual

$50.00

Volvo EC60C Compact Excavator Repair Service Manual

$50.00

Doosan DX255 Excavator Service Manual

$34.00

The Doosan DX255 Excavator Service Repair Manual is an essential PDF guide comprising 826 pages. It is designed to provide comprehensive service and repair information for serial numbers 5001 and up.

Format: PDF

Language: English

Publication Number: K1016585E

Doosan DX255 Excavator Service Manual

Product Overview

Access the comprehensive Doosan DX255 Excavator Service Manual, your go-to resource for maintaining and servicing the DX255 model. This manual, published under Publication No: K1016585E, is available in PDF format and written in English. It is applicable for serial numbers 5001 and up and spans a detailed 826 pages.

Key Features

- Format: PDF

- Language: English

- Total Pages: 826

- Serial Number Range: 5001 and Up

Benefits

- Step-by-step service procedures with photographs and drawings for clarity.

- Comprehensive information including a table of contents for easy navigation.

- Schematic diagrams available for troubleshooting major engine systems.

- Detailed safety precautions and warnings clearly outlined.

Usage Recommendations

- Use the table of contents as a quick navigation tool to find required service procedures.

- Follow detailed procedures in sequence for effective servicing.

- Ensure safety by observing all related precautions and warnings provided in the manual.

How to Use The Doosan DX255 Excavator Guide Manual

This manual provides thorough instructions for servicing the DX255 Doosan Excavator. Procedures are broken down into logical steps, and tools for locating components are provided via images and diagrams. Ensure you review the safety information carefully to work safely.

The manual includes schematics for major engine systems in the troubleshooting sections. Check the Safety section for basic and additional precautions, and heed specific warnings that are mentioned alongside potential hazards.

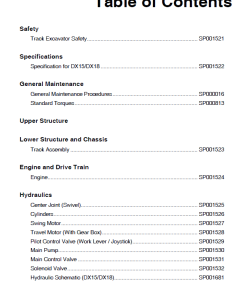

Instruction Table of Content

- Safety: Track Excavator Safety (SP000014)

- Specifications: DX255LC Specifications (SP001009)

- General Maintenance: Procedures and Standard Torques (SP000016, SP000813)

- Upper Structure: Cabin, Counterweight, Fuel Tank, Swing Gear (SP000943, SP000940, SP001012, SP001068)

- Lower Structure and Chassis: Track Assembly (SP001016)

- Engine and Drive Train: Components like Drive Coupling (SP001069)

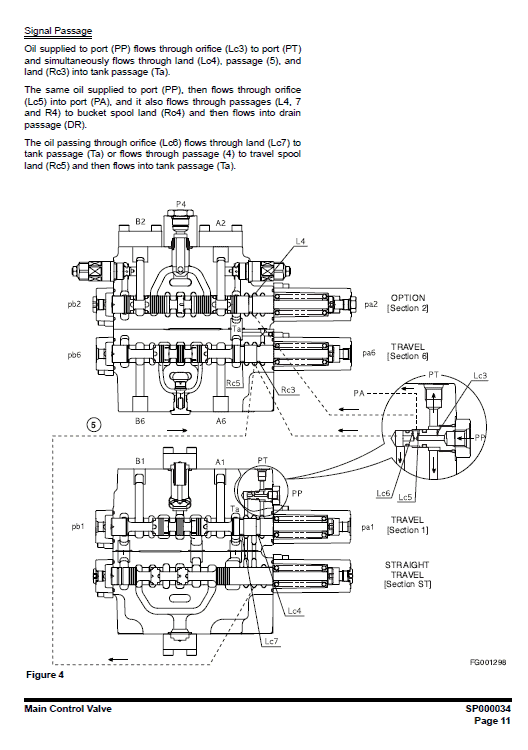

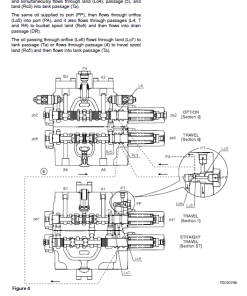

- Hydraulics: System Troubleshooting and Parts (SP001017, SP001020)

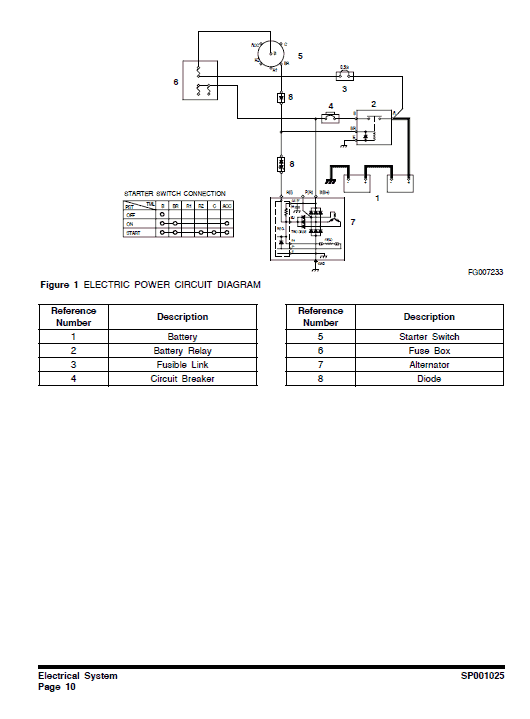

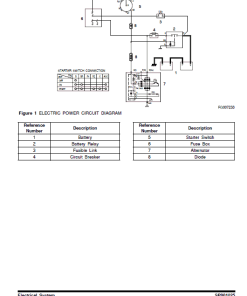

- Electrical System: Complete schematic and descriptions (SP001025)

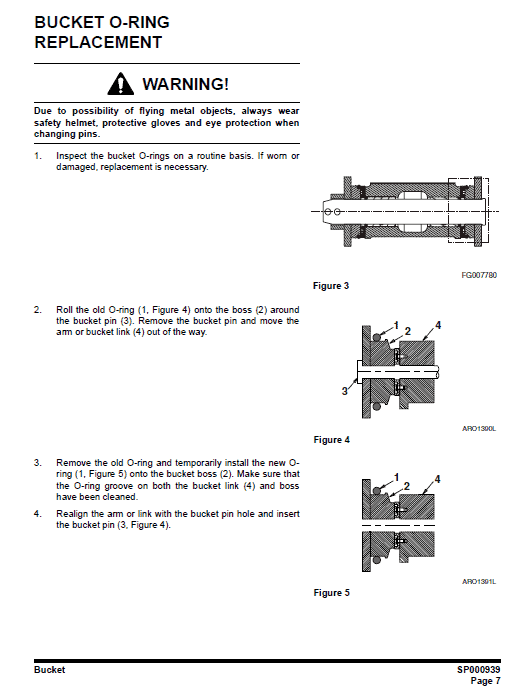

- Attachments: Boom and Arm, Bucket (SP001026, SP000939)

Manual Instruction Extract

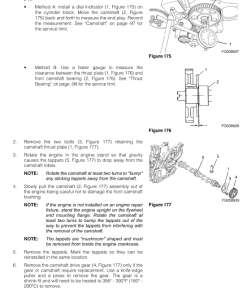

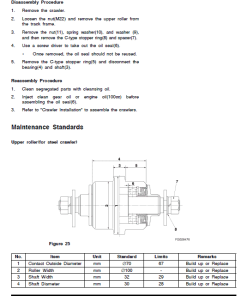

It is recommended to check the bearing displacement at least twice yearly using a dial indicator. Push the attachment against the ground to elevate the excavator, measuring at four points 90 degrees apart around the bearing circumference. Document all readings thoroughly. Note any significant increase in play, as this could indicate that the bearing is nearing the end of its service life, potentially doubling the clearances recorded when new.

Only logged in customers who have purchased this product may leave a review.

Related products

$34.00

$34.00

$33.00

$34.00

$33.00

$34.00

$34.00

Reviews

There are no reviews yet.