Doosan DX62R-3 and DX63-3 Excavator Service Manual

Product Overview

The Doosan DX62R-3 and DX63-3 Excavator Service Manual is an essential resource for maintaining and servicing your excavators. This comprehensive manual is formatted as a PDF and written in English. It covers serial numbers starting at 1001 and up and comprises 1,182 pages of detailed instructions. The publication number for this manual is 950106-01085E.

How to Use the Service Manual

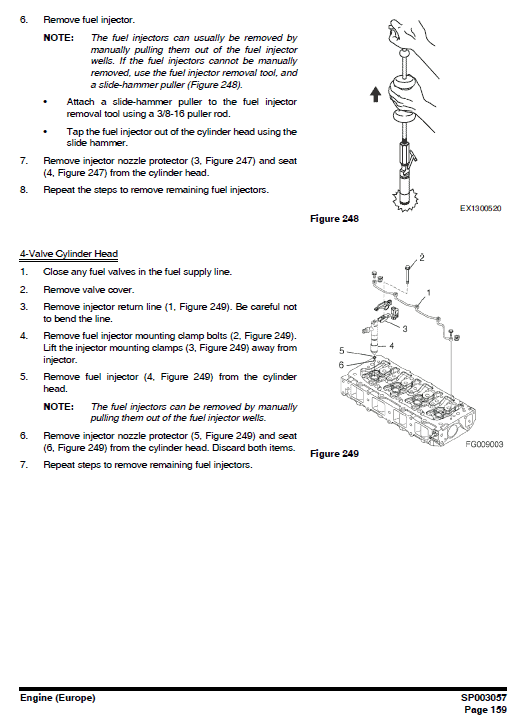

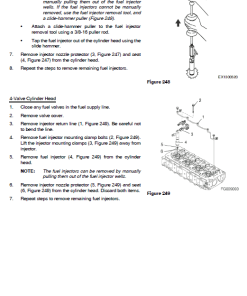

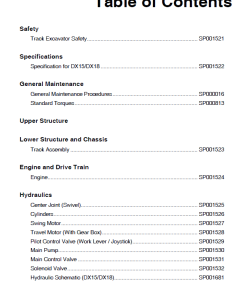

This guide is meticulously structured to assist technicians in performing service procedures on Doosan DX62R-3 and DX63-3 excavators. Each service protocol is clearly outlined in a step-by-step format, illustrated with photographs and diagrams for easy component identification. The Table of Contents is your primary reference for locating specific maintenance tasks.

Safety is a top priority, with essential precautions outlined in both this manual and the attached owner/operator documentation. Warning labels are also strategically placed on the equipment to highlight potential hazards.

Key Features

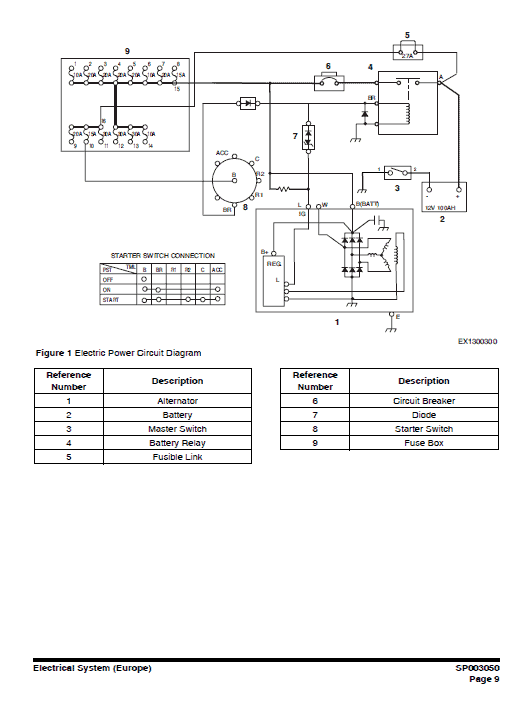

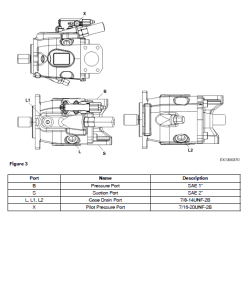

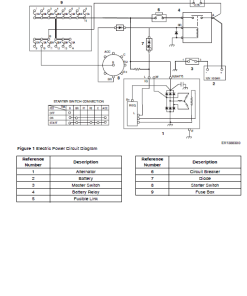

- Detailed schematics for major engine systems.

- Sophisticated troubleshooting section for various systems.

- Clear safety instructions and comprehensive safety section.

- Table of Contents for easy navigation.

Benefits

- Helps enhance the operational lifespan of your equipment with proper maintenance.

- Ensures safe operation by following structured service instructions.

- Supports maintenance efficiency and accuracy with clear visual aids.

Usage Recommendations

- Always observe the safety instructions prior to commencing any maintenance task.

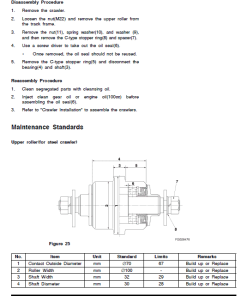

- Use the manual as a step-by-step guide for component servicing and repairs.

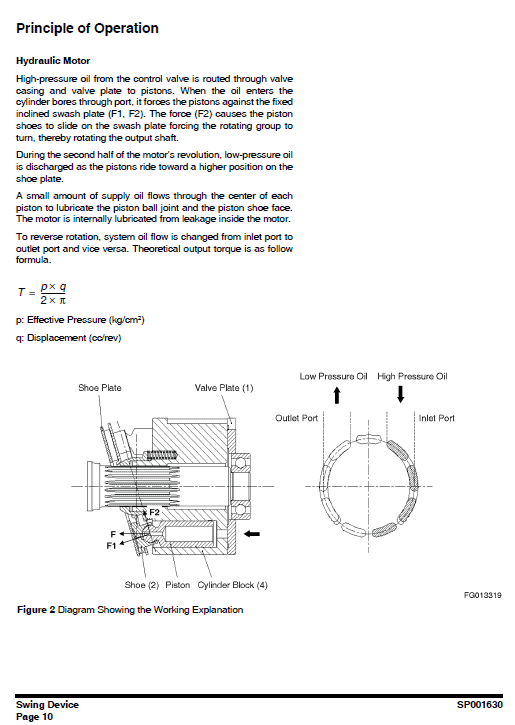

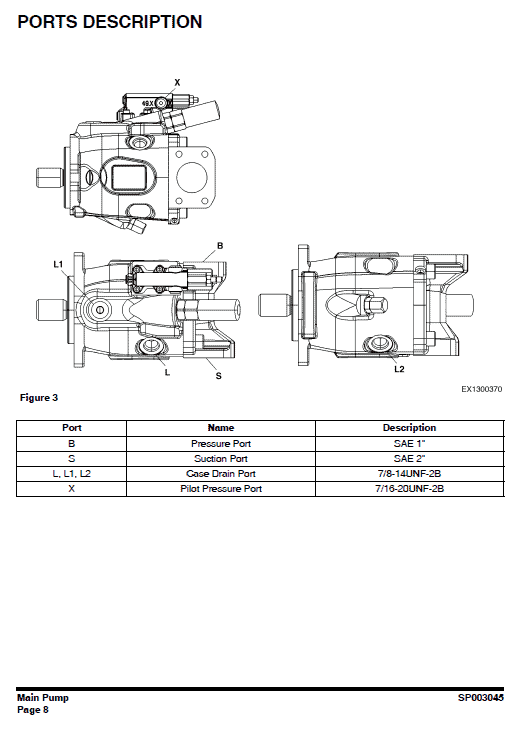

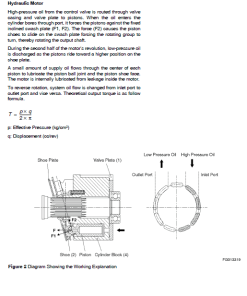

- Refer to schematics when troubleshooting engine or hydraulic issues.

Contents of the Manual

The Doosan DX62R-3 and DX63-3 manual includes sections such as:

- Safety

- Track Excavator Maintenance

- Specifications for both models

- General and specific maintenance instructions

- Details on upper and lower structure components

- Engine, hydraulic systems, and electric system specifics

- Attachments and additional equipment guidance

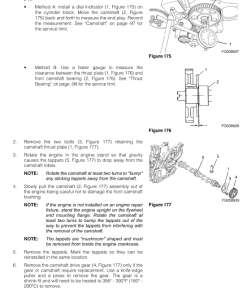

Sample Instructions

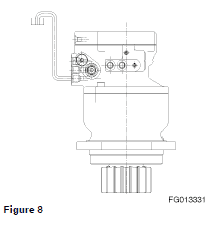

Installation and Piping

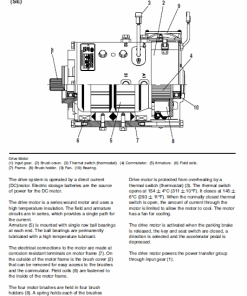

- Ensure the motor shaft is installed facing downward with below 0.05 mm concentricity.

- Tightening torques for mounting bolts should be referenced from the assembly drawing.

- The casing must remain oil-filled, with the drain returning to a higher tank level.

- Maintain routine casing pressure below 2 kg/cm2; max tolerance is 3 kg/cm2.

- Thoroughly clean and flush piping before use.

- Drain pipes should be larger than the port size and as short as possible.

Oil Filling and Air Ventilation

- Fill oil using the drain port to prevent component damage.

- Ensure all air is bled prior to operation.

Instructions Before Operation

- Verify the correct direction of motor revolution.

- Inspect for oil leaks around the motor.

- Monitor equipment for abnormal vibration or rapid temperature increases.

- Ensure all piping is securely connected.

Only logged in customers who have purchased this product may leave a review.

New Holland TS125A, TS130A, TS135A Tractor Service Manual

New Holland TS125A, TS130A, TS135A Tractor Service Manual  John Deere 2243 Mower Repair Technical Manual (TM1473)

John Deere 2243 Mower Repair Technical Manual (TM1473)  New Holland T3.50F, T3.55F, T3.65F, T3.75F Tractor Service Manual

New Holland T3.50F, T3.55F, T3.65F, T3.75F Tractor Service Manual  New Holland T14.70 RS, T14.80 RS Tractor Service Manual

New Holland T14.70 RS, T14.80 RS Tractor Service Manual

Reviews

There are no reviews yet.