Gehl Z45 Gen 2, Mustang 450Z Nxt 2 Compact Excavator Repair Service Manual

$40.00

Explore comprehensive manuals available in PDF format for the Gehl Excavator, specifically designed for Model Gehl Z45 Gen 2 and Mustang 450Z Nxt 2.

Comprehensive Maintenance Manual

Product Overview

This maintenance manual is an essential guide for professionals working with hydraulic and heavy machinery. It covers a wide range of critical topics, including safety precautions, technical specifications, servicing standards, and troubleshooting techniques, all crucial for maintaining equipment in optimal condition.

Key Features

- General Cautions for Maintenance Work:

- Safety guidelines and best practices for handling hydraulic equipment, seals, and hoses.

- Instructions for proper disassembly, reassembly, and air release in hydraulic systems.

- Technical Data:

- Specifications for machines, including working area dimensions and main part weights.

- Hydraulic and electrical schematics, wiring diagrams, and recommended lubricants.

- Regular inspection schedules and lifting capacity details.

- Service Standards:

- Performance criteria for engine, undercarriage, and hydraulic equipment.

- Specifications for rubber crawlers, blade devices, and bucket teeth.

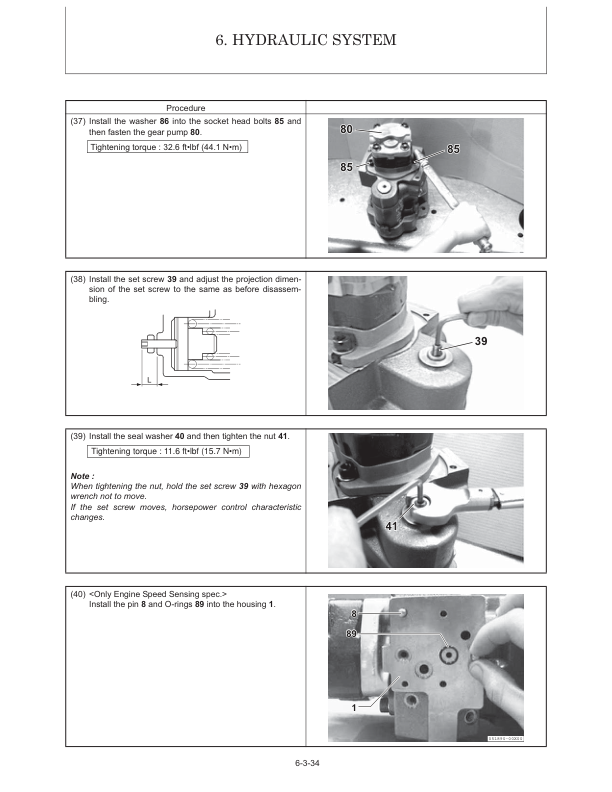

- Tightening torque values and pressure adjustments for hydraulic components.

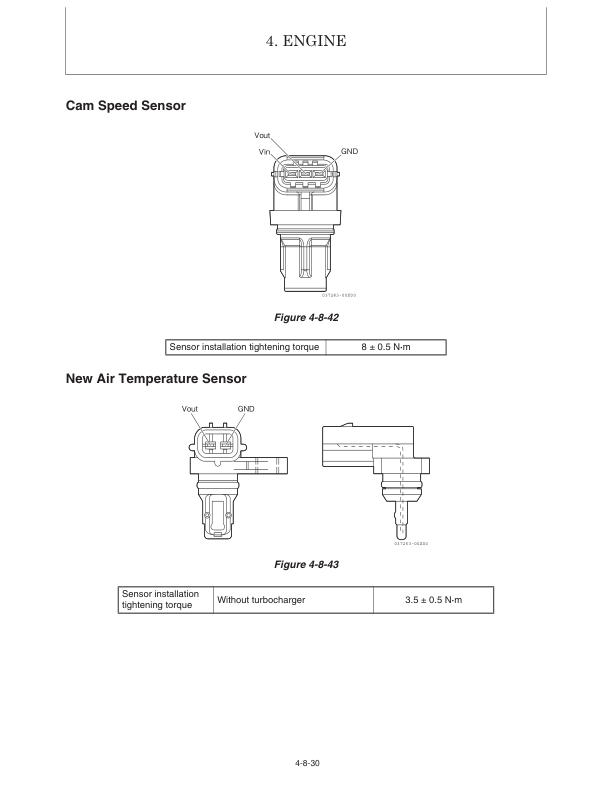

- Engine:

- Detailed servicing methods, including valve clearance, EGR system, and crankshaft/camshaft maintenance.

- Guidelines for fuel, cooling, lubrication systems, and electric components.

- Troubleshooting tips and wiring diagrams for engine-related issues.

- Electric System:

- Exploration of electrical components’ layout and functionality, including LCD monitor and alarm systems.

- Description of electronic control systems for start/stop, auto deceleration, and Eco mode.

- Error codes and diagnostic information for electrical fault troubleshooting.

- Hydraulic System:

- Comprehensive circuit operations for boom, arm, bucket, swing, and blade systems.

- Scenarios for simultaneous operations and options like quick couplers and hydraulic P.T.O.

- Maintenance guidelines for critical components such as pumps, valves, and motors.

- Adjustment and Repair:

- Instructions for removal and reinstallation of major components like engine and controls.

- Guidance on hydraulic system repairs including cylinders and swivel joints.

- Work implement adjustments, including quick coupler servicing.

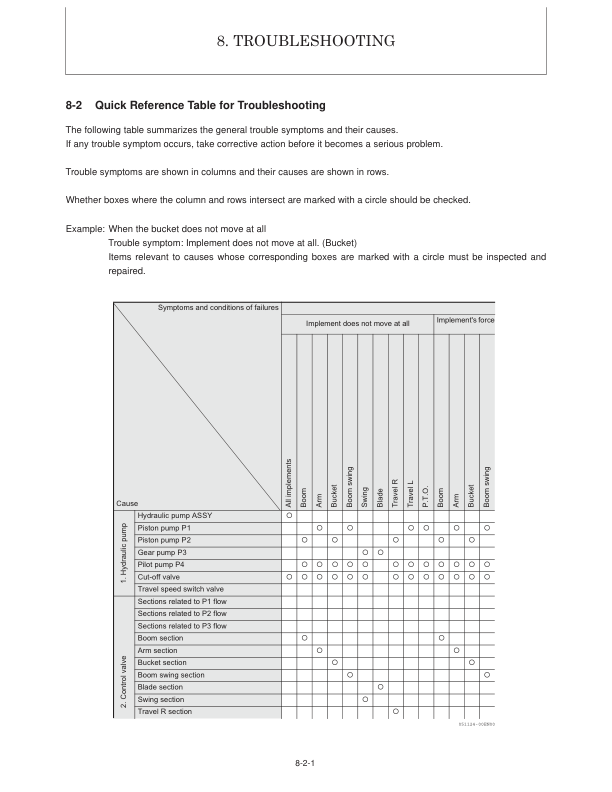

- Troubleshooting:

- Diagnostic guides for non-breakdown issues such as arm movement irregularities and thermal shocks.

- Quick reference tables for common hydraulic and electrical problems.

- Solutions for issues such as varying hydraulic oil levels and travel speed delays.

Benefits

- Enhanced Safety: Adhere to outlined precautions to ensure the safe operation and maintenance of machinery.

- Improved Efficiency: Utilize detailed schematics and diagrams to streamline maintenance processes.

- Prolonged Equipment Life: Follow regular servicing standards and best practices to maintain machinery longevity.

Usage Recommendations

- Ideal for technicians and engineers involved in the maintenance of hydraulic machinery.

- Refer to this manual for scheduled inspections and performance checks to ensure safety and efficiency.

- Use troubleshooting guides to quickly resolve operational issues and minimize downtime.

Only logged in customers who have purchased this product may leave a review.

Related products

$36.00

Articulated Loader

$36.00

Articulated Loader

$36.00

$36.00

$29.00

$36.00

Still ESM10 Counter Balanced Workshop Repair Manual

Still ESM10 Counter Balanced Workshop Repair Manual

Reviews

There are no reviews yet.