-

×

Hyundai R55W-7A Wheel Excavator Service Repair Manual

$34.00

Hyundai R55W-7A Wheel Excavator Service Repair Manual

$34.00 -

×

Hyundai HX55A CR Crawler Excavator Service Repair Manual

$34.00

Hyundai HX55A CR Crawler Excavator Service Repair Manual

$34.00 -

×

Hyundai R330LC-9A Crawler Excavator Service Repair Manual

$35.00

Hyundai R330LC-9A Crawler Excavator Service Repair Manual

$35.00 -

×

Hyundai HX160 L, HX180 L Crawler Excavator Service Repair Manual

$35.00

Hyundai HX160 L, HX180 L Crawler Excavator Service Repair Manual

$35.00 -

×

Hyundai HX300 L Crawler Excavator Service Repair Manual

$36.00

Hyundai HX300 L Crawler Excavator Service Repair Manual

$36.00 -

×

Hyundai HX500A L Crawler Excavator Service Repair Manual

$34.00

Hyundai HX500A L Crawler Excavator Service Repair Manual

$34.00 -

×

Hyundai HX35A Z Crawler Excavator Service Repair Manual

$34.00

Hyundai HX35A Z Crawler Excavator Service Repair Manual

$34.00 -

×

Hyundai R27Z-9 Crawler Excavator Service Repair Manual

$34.00

Hyundai R27Z-9 Crawler Excavator Service Repair Manual

$34.00 -

×

Hyundai HX480S L, HX520S L Crawler Excavator Service Repair Manual

$35.00

Hyundai HX480S L, HX520S L Crawler Excavator Service Repair Manual

$35.00 -

×

Hyundai R130S (Smart+) Crawler Excavator Service Repair Manual (Built in India)

$34.00

Hyundai R130S (Smart+) Crawler Excavator Service Repair Manual (Built in India)

$34.00 -

×

Hyundai R320LC-3 Crawler Excavator Service Repair Manual

$34.00

Hyundai R320LC-3 Crawler Excavator Service Repair Manual

$34.00 -

×

Hyundai HX17A Z Crawler Excavator Service Repair Manual

$34.00

Hyundai HX17A Z Crawler Excavator Service Repair Manual

$34.00 -

×

Hyundai R180LC-7 Crawler Excavator Service Repair Manual

$34.00

Hyundai R180LC-7 Crawler Excavator Service Repair Manual

$34.00 -

×

Hyundai HX300HD Crawler Excavator Service Repair Manual

$34.00

Hyundai HX300HD Crawler Excavator Service Repair Manual

$34.00 -

×

Hyundai R450LC-7 Crawler Excavator Service Repair Manual

$35.00

Hyundai R450LC-7 Crawler Excavator Service Repair Manual

$35.00 -

×

Hyundai HX300LT3 Crawler Excavator Service Repair Manual

$34.00

Hyundai HX300LT3 Crawler Excavator Service Repair Manual

$34.00 -

×

Hyundai HX430 L Crawler Excavator Service Repair Manual

$35.00

Hyundai HX430 L Crawler Excavator Service Repair Manual

$35.00 -

×

Hyundai R220LC-9S Crawler Excavator Service Repair Manual (Built in Brazil)

$35.00

Hyundai R220LC-9S Crawler Excavator Service Repair Manual (Built in Brazil)

$35.00 -

×

Hyundai HX260 L Crawler Excavator Service Repair Manual

$35.00

Hyundai HX260 L Crawler Excavator Service Repair Manual

$35.00 -

×

Hyundai R180LC-3 Crawler Excavator Service Repair Manual

$34.00

Hyundai R180LC-3 Crawler Excavator Service Repair Manual

$34.00 -

×

Hyundai R170W-7A Wheel Excavator Service Repair Manual

$35.00

Hyundai R170W-7A Wheel Excavator Service Repair Manual

$35.00 -

×

Hyundai R140LC-7 Crawler Excavator Service Repair Manual

$34.00

Hyundai R140LC-7 Crawler Excavator Service Repair Manual

$34.00 -

×

Hyundai R140LC-9V Crawler Excavator Service Repair Manual (Built in India)

$34.00

Hyundai R140LC-9V Crawler Excavator Service Repair Manual (Built in India)

$34.00 -

×

Hyundai R260LC-9S Crawler Excavator Service Repair Manual (Built in Brazil)

$34.00

Hyundai R260LC-9S Crawler Excavator Service Repair Manual (Built in Brazil)

$34.00 -

×

Hyundai R145CR-9 Crawler Excavator Service Repair Manual

$34.00

Hyundai R145CR-9 Crawler Excavator Service Repair Manual

$34.00 -

×

Hyundai R360LC-7 Crawler Excavator Service Repair Manual

$34.00

Hyundai R360LC-7 Crawler Excavator Service Repair Manual

$34.00 -

×

Hyundai HX1000L Crawler Excavator Service Repair Manual

$35.00

Hyundai HX1000L Crawler Excavator Service Repair Manual

$35.00 -

×

Hyundai R380LC-9SH Crawler Excavator Service Repair Manual

$35.00

Hyundai R380LC-9SH Crawler Excavator Service Repair Manual

$35.00 -

×

Hyundai R140W-7A Wheel Excavator Service Repair Manual

$35.00

Hyundai R140W-7A Wheel Excavator Service Repair Manual

$35.00 -

×

Hyundai R370LC-7 Crawler Excavator Service Repair Manual

$34.00

Hyundai R370LC-7 Crawler Excavator Service Repair Manual

$34.00 -

×

Hyundai R55-7A Crawler Excavator Service Repair Manual

$34.00

Hyundai R55-7A Crawler Excavator Service Repair Manual

$34.00 -

×

Hyundai R140W-7 Wheel Excavator Service Repair Manual

$35.00

Hyundai R140W-7 Wheel Excavator Service Repair Manual

$35.00 -

×

Hyundai R140LC-9A Crawler Excavator Service Repair Manual

$34.00

Hyundai R140LC-9A Crawler Excavator Service Repair Manual

$34.00 -

×

Hyundai R800LC-7A Crawler Excavator Service Repair Manual

$34.00

Hyundai R800LC-7A Crawler Excavator Service Repair Manual

$34.00 -

×

Hyundai R145CR-9A Crawler Excavator Service Repair Manual

$34.00

Hyundai R145CR-9A Crawler Excavator Service Repair Manual

$34.00 -

×

Hyundai R215 (Smart+) Crawler Excavator Service Repair Manual (Built in India)

$34.00

Hyundai R215 (Smart+) Crawler Excavator Service Repair Manual (Built in India)

$34.00 -

×

Hyundai R250LC-7A Crawler Excavator Service Repair Manual

$34.00

Hyundai R250LC-7A Crawler Excavator Service Repair Manual

$34.00

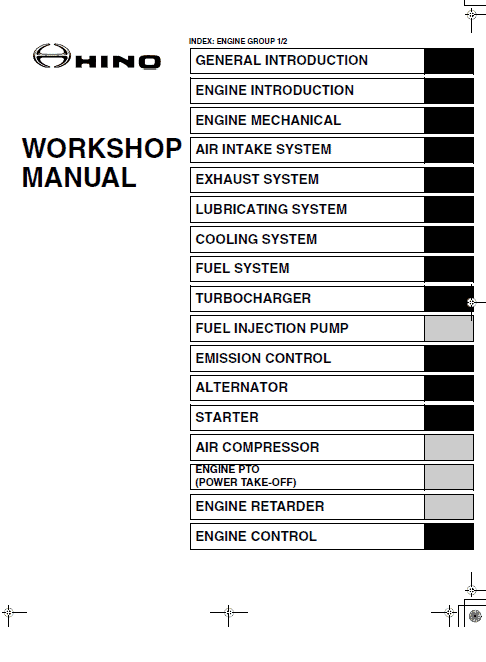

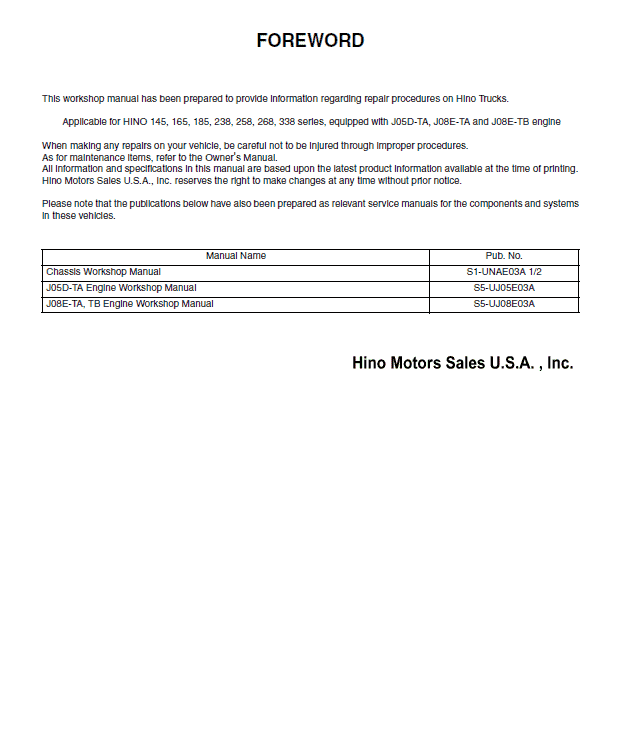

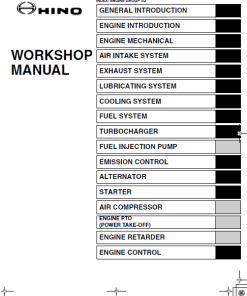

Hino 145, 165, 185, 238, 268, 308, 338 Series Year 2007 Repair Manual

$36.00

Optimize your maintenance for the Hino Truck 2007 series with our comprehensive Repair and Service Manual. This manual covers the 145 (NA6J), 165 (NB6J), 185 (NC6J), 238 (ND8J), 268 (NE8J, NJ8J), 308 (NF8J), and 338 (NV8J) series, equipped with J05D-TA, J08E-TA, and J08E-TB engines.

Format: PDF

Language: English

SKU: 297711

Category: Hino

Hino Series 145, 165, 185, 238, 268, 338 – 2007 Repair Manual

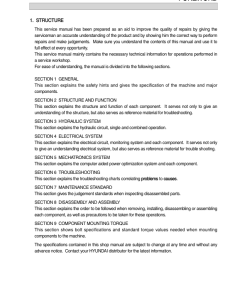

Product Overview

The Hino Truck 2007 Repair and Service Manual provides comprehensive guidance for Hino Series 145, 165, 185, 238, 268, and 338. This valuable resource facilitates efficient maintenance and repair of trucks equipped with J05D-TA, J08E-TA, and J08E-TB engines.

Available in PDF format, this manual is meticulously crafted in English, ensuring easy accessibility and understanding for operators and service professionals.

Key Features

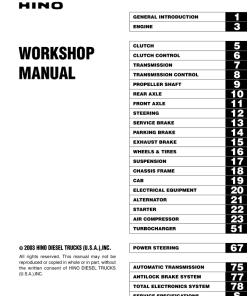

- Detailed Hino 2007 Series Manual – 1162 Pages

- Comprehensive Hino Owners Manual – 274 Pages

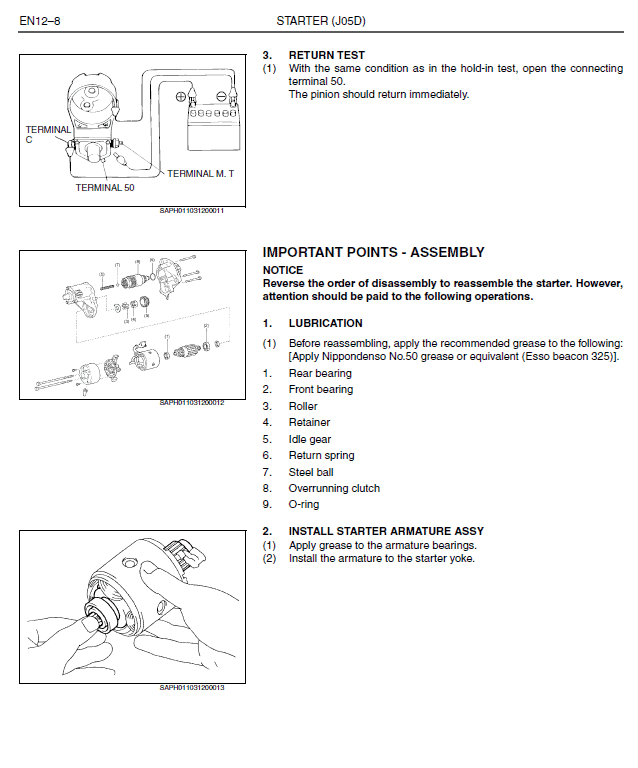

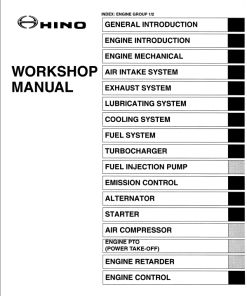

- Specific J05D-TA Engine Manual – 324 Pages

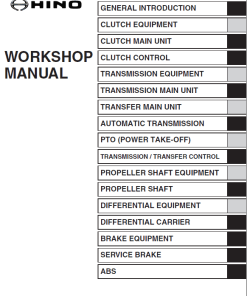

- Comprehensive J08E-TA and J08E-TB Engine Manual – 351 Pages

Benefits

- Provides critical insights for smooth, safe, and economical vehicle operation.

- Includes necessary maintenance and troubleshooting procedures.

- Ensures adherence to the latest specifications and standards.

Usage Recommendations

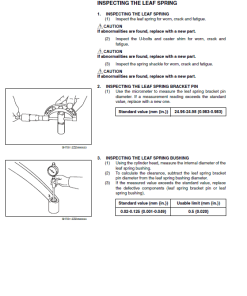

- Perform regular inspections to prevent wear and tear.

- Follow outlined maintenance procedures to ensure optimal performance.

- Consult the manual for specific repair recommendations.

- Exercise caution and follow safe practices to prevent injuries during repairs.

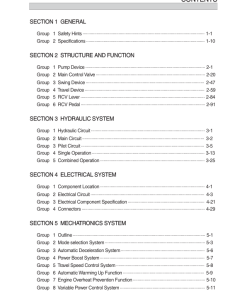

Table of Contents

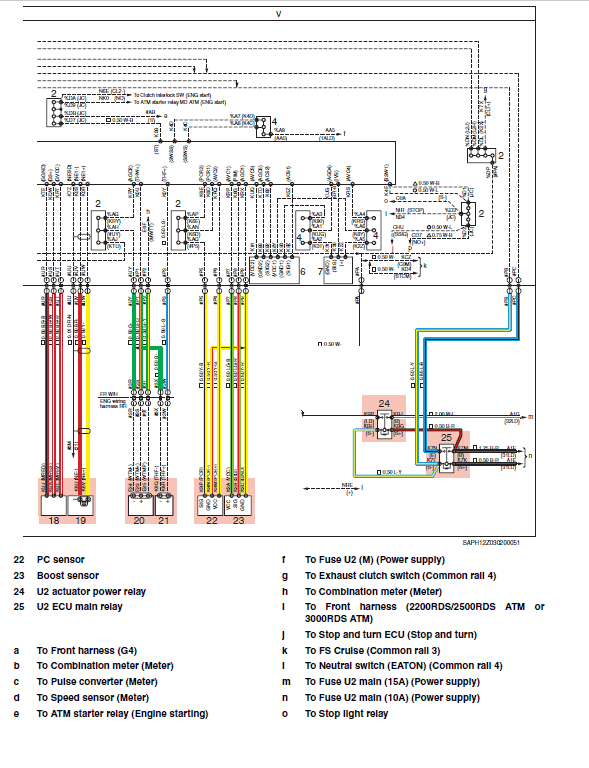

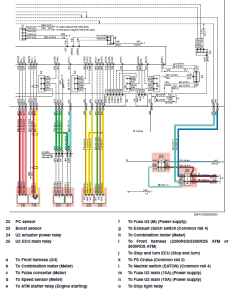

This manual covers a broad range of topics including:

- General Introduction

- Clutch Equipment

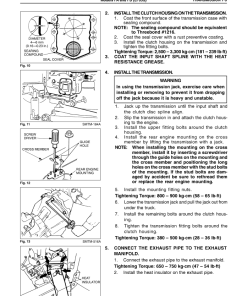

- Transmission and Transfer Systems

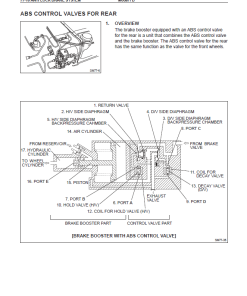

- Braking Systems (including ABS and ASR)

- Steering and Power Steering Equipment

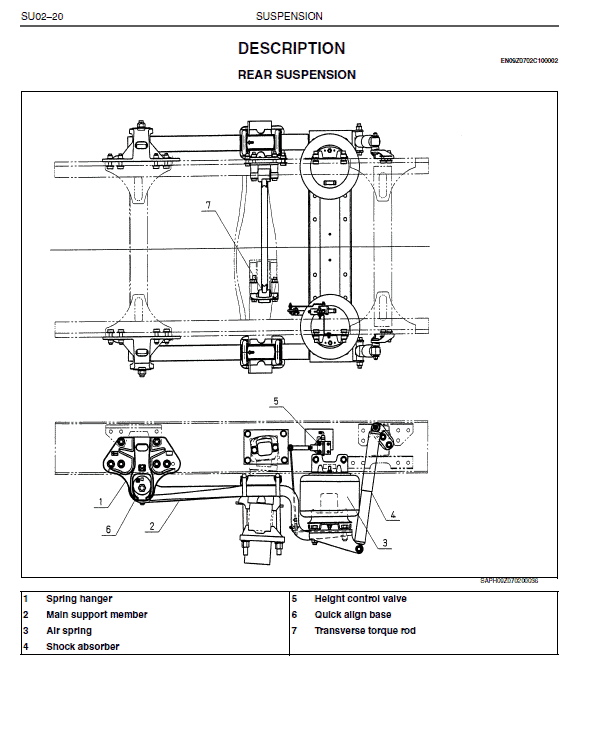

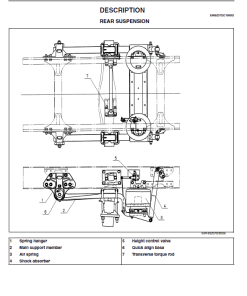

- Axle Equipment and Chassis Components

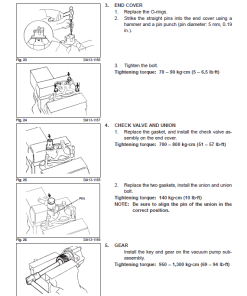

Instruction Extracts

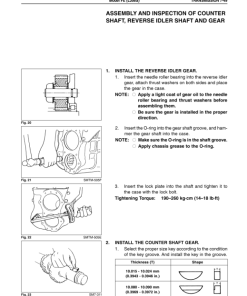

Inspection and Repair

To ensure safety during vehicle maintenance:

- Always use proper eye protection.

- Wear protective clothing and work in well-ventilated areas.

- Avoid using flammable or explosive solvents such as gasoline.

- Follow manufactureru2019s instructions for solvent cleaners carefully.

Cleaning Procedures

- Ground and Polished Parts: Use cleaning solvents like kerosene or diesel; avoid hot solution tanks.

- Rough Parts: Use diluted alkaline solutions for cleaning when appropriate, followed by thorough washing with water.

Drying and Corrosion Prevention

- Dry parts immediately using soft cloths; avoid using compressed air on bearings.

- Apply axle lubricant and anti-corrosion materials to cleaned parts before storage.

Inspection of Parts

Inspect all parts for wear before assembly. Pay particular attention to signs of wear in tapered roller bearings and replace any faulty components as needed.

For more detailed instructions and safety measures, refer to the specific sections within the manual.

Only logged in customers who have purchased this product may leave a review.

Related products

$36.00

$36.00

Reviews

There are no reviews yet.