-

×

Bobcat T62 Compact Track Loader Service Repair Manual

$36.00

Bobcat T62 Compact Track Loader Service Repair Manual

$36.00 -

×

Case 1080, 1080B Excavator Service Manual

$36.00

Case 1080, 1080B Excavator Service Manual

$36.00 -

×

Volvo PT220RH Asphalt Compactors Repair Service Manual

$46.00

Volvo PT220RH Asphalt Compactors Repair Service Manual

$46.00 -

×

BT RRX35, RRX45, RDX30, RSX40, RSX50 Rider Truck Service Manual

$27.00

BT RRX35, RRX45, RDX30, RSX40, RSX50 Rider Truck Service Manual

$27.00 -

×

BT LT 2200-6, LT 2200-8 Pallet Truck Service Manual

$26.00

BT LT 2200-6, LT 2200-8 Pallet Truck Service Manual

$26.00 -

×

HONDA ACCORD 2008, 2009, 2010 Factory Repair Service Workshop Manual

$22.00

HONDA ACCORD 2008, 2009, 2010 Factory Repair Service Workshop Manual

$22.00 -

×

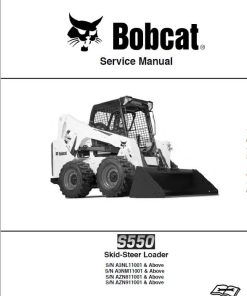

Bobcat S550 Skid-Steer Loader Service Repair Manual

$36.00

Bobcat S550 Skid-Steer Loader Service Repair Manual

$36.00 -

×

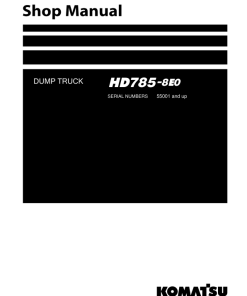

Komatsu HD785-8E0 Dump Truck Service Repair Manual

$55.00

Komatsu HD785-8E0 Dump Truck Service Repair Manual

$55.00 -

×

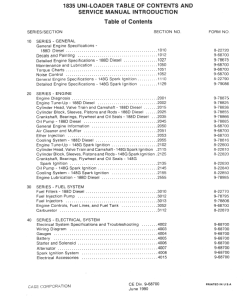

Case 1835 Uni-Loader SkidSteer Service Manual

$34.00

Case 1835 Uni-Loader SkidSteer Service Manual

$34.00 -

×

Case 850M Crawler Dozer Service Manual

$36.50

Case 850M Crawler Dozer Service Manual

$36.50 -

×

Bobcat 645 Skid-Steer Loader Service Repair Manual

$27.00

Bobcat 645 Skid-Steer Loader Service Repair Manual

$27.00 -

×

AGCO ST34A, ST41A Tractor Service Manual

$35.00

AGCO ST34A, ST41A Tractor Service Manual

$35.00 -

×

Bobcat 425 and 428 Compact Excavator Service Manual

$34.00

Bobcat 425 and 428 Compact Excavator Service Manual

$34.00 -

×

Bobcat T36.120SL, T36.120SLRB versaHANDLER Telescopic Service Repair Manual

$38.00

Bobcat T36.120SL, T36.120SLRB versaHANDLER Telescopic Service Repair Manual

$38.00 -

×

BT P24 Pallet Truck Repair Service Manual

$24.00

BT P24 Pallet Truck Repair Service Manual

$24.00 -

×

Case 580, 590, 695 Super R Backhoe Loader Service Manual

$34.00

Case 580, 590, 695 Super R Backhoe Loader Service Manual

$34.00 -

×

Case 680K Loader Backhoe Service Manual

$35.00

Case 680K Loader Backhoe Service Manual

$35.00

Hitachi ZX290LC-5B and ZX290LCN-5B ZAXIS Excavator Repair Manual

$35.00

Format: PDF

Language: English

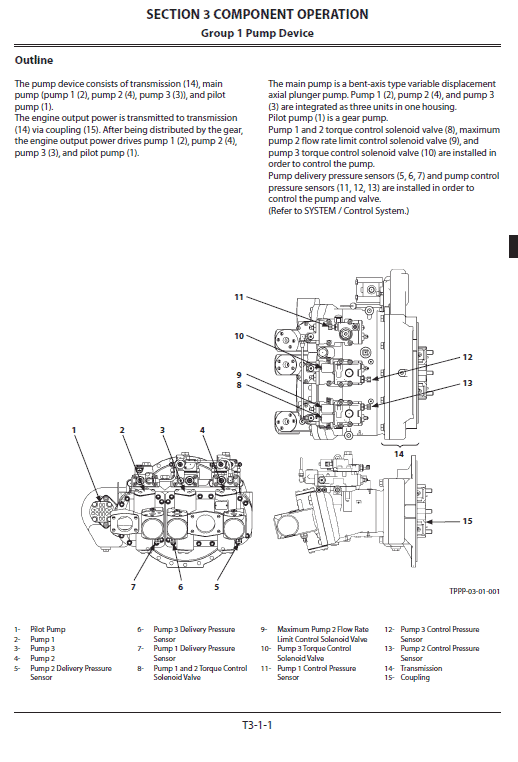

Enhance your maintenance and troubleshooting capabilities with the comprehensive Service Repair Manual for Hitachi ZAXIS ZX290LC-5B and ZX290LCN-5B. This manual includes the following volumes:

Hitachi ZX290LC-5B and ZX290LCN-5B ZAXIS Excavator Manual

Product Overview

This comprehensive manual is specifically designed for the Hitachi Excavator models ZX290LC-5B and ZX290LCN-5B. It is available in PDF format, written in English, ensuring easy access and understanding for all users.

Specifications

- Format: PDF

- Language: English

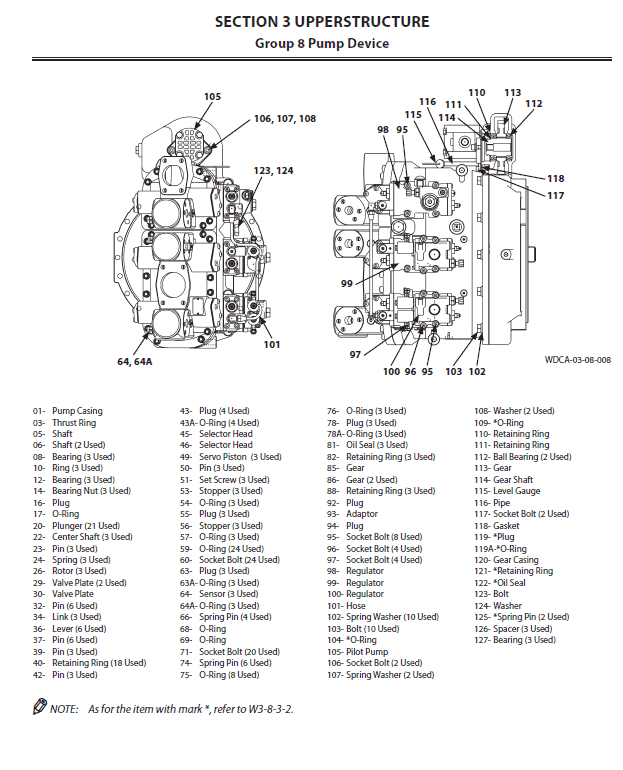

Manual Components

The service manual is a detailed compilation that includes:

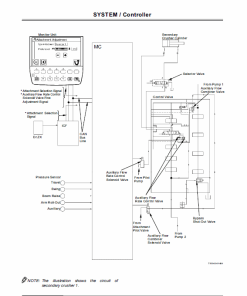

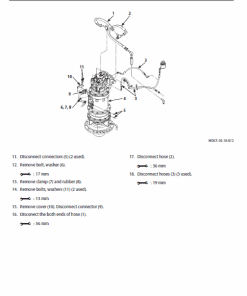

- Service Manual (Troubleshooting): Vol. No. TODDA-EN (500 Pages)

- Service Manual (Operation): Vol. No. TTDDA-EN (440 Pages)

- Workshop Manual: Vol. No. WDDA-EN (583 Pages)

- Circuit Diagram: 15 Pages

This manual uses the International System of Units (SI Units) for all technical information and procedures.

Manual Guide Composition

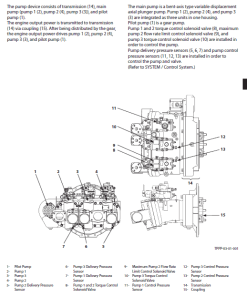

The Hitachi ZAXIS ZX290LC-5B and ZX290LCN-5B service manual is broken down into three critical sections:

- Service Manual: Provides essential technical information for redelivery and delivery tasks, operating and activating all devices and systems, conducting operational performance tests, and troubleshooting.

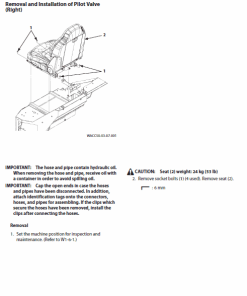

- Workshop Manual: Details the technical aspects necessary for maintaining and repairing the machine, including required tools and devices, maintenance standards, and comprehensive procedures for removing, installing, assembling, and disassembling components.

Refer to the service manual to avoid injury and damage. Use proper lifting techniques and equipment when handling heavy parts.

Benefits of Hitachi ZAXIS Technology

The new ZAXIS excavators are renowned for industry-leading hydraulic technology and unparalleled performance. These machines offer:

- Exceptional fuel efficiency, reducing operational costs.

- Swift and effortless operation.

- High quality, durability, and low maintenance costs.

The evolution of Hitachi’s technology ensures that the ZAXIS series will fulfill customers’ visions and set new standards for your projects.

Precautions: Using Floating Seal Manual Instructions

Follow these guidelines when handling floating seals:

- After disassembling, replace the floating seal with a new one. If reusing, ensure the following:

- Keep seal rings as matched sets with surfaces together. Apply oil to the seal ring’s sliding surface.

- Inspect the seal ring for scuffs, scores, corrosion, or uneven wear.

- Examine the O-ring for tears, breaks, deformations, or hardening.

- Prevent issues by ensuring correct assembly to avoid oil leakage or damage.

- Clean the floating seal and mounting bores with a detergent solvent, and thoroughly dry them with compressed air.

- Verify the seal ring and O-ring mounting bores for any surface damage.

- Upon installation, ensure the O-ring is correctly seated and not twisted regarding the seal ring.

- Ensure the seal ring’s sliding surface is parallel to the seal mating surface. Adjust the O-ring as needed if discrepancies are found.

/p>

Only logged in customers who have purchased this product may leave a review.

Related products

$49.00

$48.00

$36.00

$40.00

$45.00

$49.00

$40.00

Reviews

There are no reviews yet.