-

×

Bobcat T62 Compact Track Loader Service Repair Manual

$36.00

Bobcat T62 Compact Track Loader Service Repair Manual

$36.00 -

×

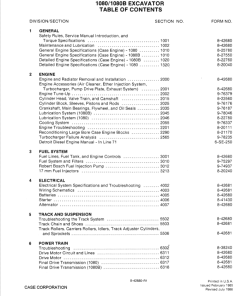

Case 1080, 1080B Excavator Service Manual

$36.00

Case 1080, 1080B Excavator Service Manual

$36.00 -

×

Volvo PT220RH Asphalt Compactors Repair Service Manual

$46.00

Volvo PT220RH Asphalt Compactors Repair Service Manual

$46.00 -

×

BT RRX35, RRX45, RDX30, RSX40, RSX50 Rider Truck Service Manual

$27.00

BT RRX35, RRX45, RDX30, RSX40, RSX50 Rider Truck Service Manual

$27.00 -

×

BT LT 2200-6, LT 2200-8 Pallet Truck Service Manual

$26.00

BT LT 2200-6, LT 2200-8 Pallet Truck Service Manual

$26.00 -

×

HONDA ACCORD 2008, 2009, 2010 Factory Repair Service Workshop Manual

$22.00

HONDA ACCORD 2008, 2009, 2010 Factory Repair Service Workshop Manual

$22.00 -

×

Bobcat S550 Skid-Steer Loader Service Repair Manual

$36.00

Bobcat S550 Skid-Steer Loader Service Repair Manual

$36.00 -

×

Komatsu HD785-8E0 Dump Truck Service Repair Manual

$55.00

Komatsu HD785-8E0 Dump Truck Service Repair Manual

$55.00 -

×

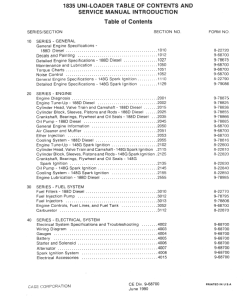

Case 1835 Uni-Loader SkidSteer Service Manual

$34.00

Case 1835 Uni-Loader SkidSteer Service Manual

$34.00 -

×

Case 850M Crawler Dozer Service Manual

$36.50

Case 850M Crawler Dozer Service Manual

$36.50 -

×

Bobcat 645 Skid-Steer Loader Service Repair Manual

$27.00

Bobcat 645 Skid-Steer Loader Service Repair Manual

$27.00 -

×

AGCO ST34A, ST41A Tractor Service Manual

$35.00

AGCO ST34A, ST41A Tractor Service Manual

$35.00 -

×

Bobcat 425 and 428 Compact Excavator Service Manual

$34.00

Bobcat 425 and 428 Compact Excavator Service Manual

$34.00 -

×

Bobcat T36.120SL, T36.120SLRB versaHANDLER Telescopic Service Repair Manual

$38.00

Bobcat T36.120SL, T36.120SLRB versaHANDLER Telescopic Service Repair Manual

$38.00

Hitachi ZX350LC-6 and ZX350LCN-6 ZAXIS Excavator Service Repair Manual

$35.00

The service manual is designed for the Hitachi ZX350LC-6 and ZX350LCN-6 Excavator models.

Format: PDF

Language: English

The manual includes the following comprehensive service documents:

Hitachi ZX350LC-6 and ZX350LCN-6 ZAXIS Excavator Manual

Product Overview

This comprehensive manual is intended for operators and technicians of the Hitachi ZX350LC-6 and ZX350LCN-6 Excavator models. Available in PDF format, this English-language manual provides detailed information for troubleshooting, operation, and maintenance tasks.

The service manual package includes:

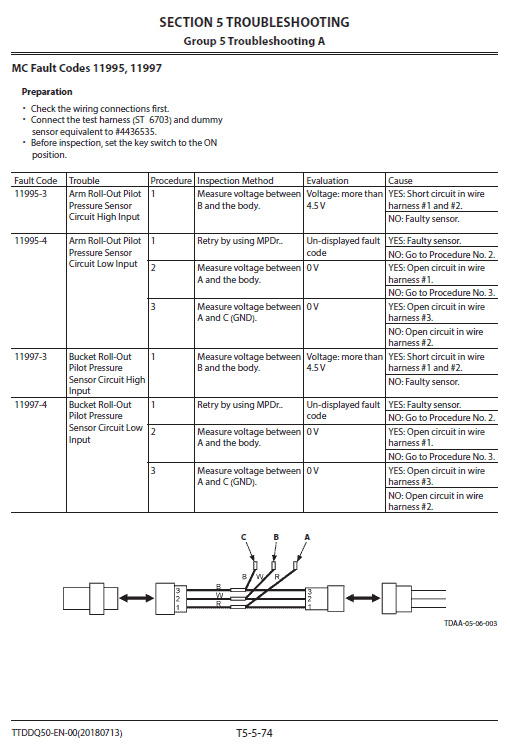

- Troubleshooting Manual: Vol. No. TODDQ50-EN, spanning 548 pages.

- Operation Manual: Vol. No. TTDDQ50-EN, spanning 478 pages.

- Workshop Manual: Vol. No. WDDQ50-EN, spanning 689 pages.

- Circuit Diagram: 15 pages.

All manuals utilize SI Units (International System of Units).

Manual Guide Composition

The Hitachi ZX350LC-6 and ZX350LCN-6 service manual covers three major sections: Operating, Troubleshooting, and Workshop Manual.

- Service Manual: Includes technical information needed for redelivery and delivery, device and system operations, performance tests, and troubleshooting procedures.

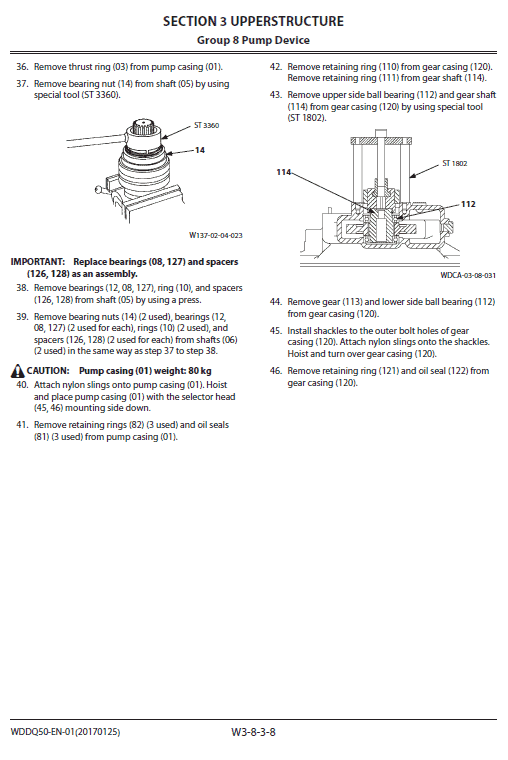

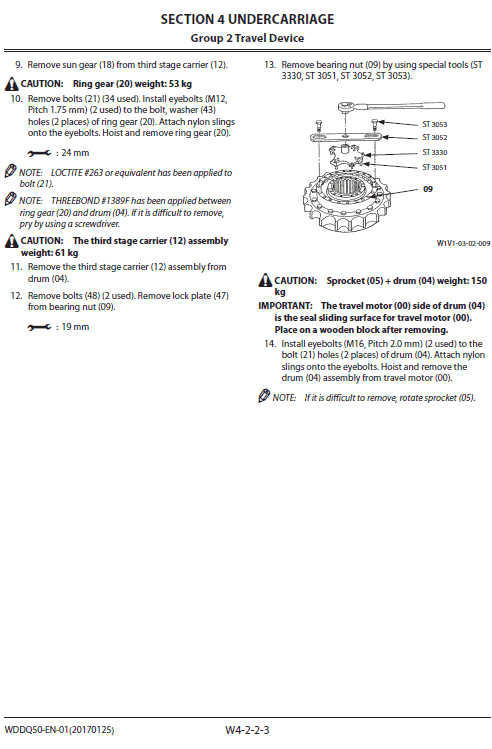

- Workshop Manual: Provides technical information for machine maintenance and repair, necessary tools, maintenance standards, and detailed procedures for component removal, installation, assembly, and disassembly.

To ensure safety and avoid damage, always follow the service manual instructions and use proper lifting techniques when handling heavy parts.

Key Features

- Detailed manuals for troubleshooting, operation, and maintenance.

- Includes circuit diagrams for deeper technical understanding.

- Designed using industry-leading hydraulic technology from Hitachi.

- Optimized for impressive fuel economy and easy operation.

Benefits

- Improves operational efficiency and reduces downtime with expert troubleshooting guidance.

- Ensures low running costs with high durability and low fuel consumption.

- Supports technicians in realizing better repair and maintenance practices.

Usage Recommendations

- Refer to the manual for safe and efficient use of the excavator.

- Utilize proper safety gear and lifting tools as advised in the manual to prevent injuries.

- Familiarize with hydraulic systems and engine operations for optimal machine performance.

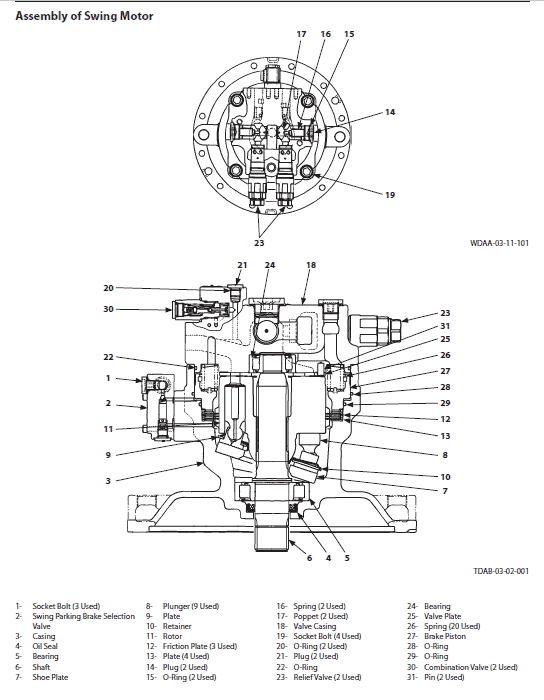

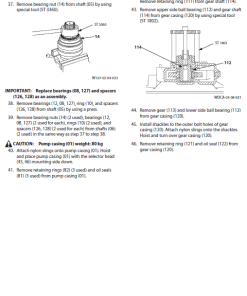

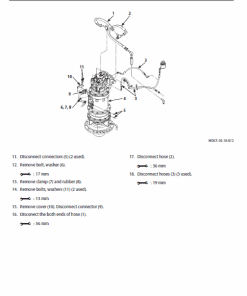

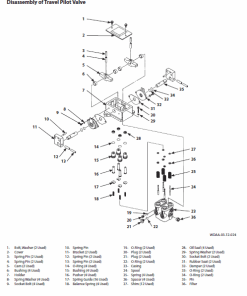

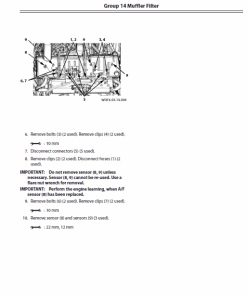

Assembly Instructions: Swing Motor

- Press-fit the inner race of bearings (5, 24) onto shaft (6), ensuring bearing (5) flanges face the shaft’s stepped part.

- Use a plate to install the oil seal (4) onto casing (3) with its lip side up.

- Cautiously hammer the outer race of bearing (5) into casing (3) using a bar.

- Tape the shaft spline to protect oil seal (4) and insert shaft (6) horizontally into casing (3).

- Install shoe plate (7) to casing (3) with the chamfered surface down and position accordingly.

- Integrate plate (9) and retainer (10) notches, then fit plungers (8) into place.

- Lubricate rotor (11) plunger holes with hydraulic oil, and mount the plunger assembly on the rotor.

- Horizontally insert rotor (11) assembly onto shaft (6) within casing (3).

- Align notches of plates (13) and friction plates (12) vertically within casing (3) for installation.

- Seal casing (3) with O-rings (28, 29) before brake piston (27) installation.

- Use matching marks”, “

Only logged in customers who have purchased this product may leave a review.

Related products

$40.00

$49.00

$40.00

$49.00

$49.00

$48.00

Reviews

There are no reviews yet.