-

×

Hyundai R55W-7A Wheel Excavator Service Repair Manual

$34.00

Hyundai R55W-7A Wheel Excavator Service Repair Manual

$34.00 -

×

Hyundai HX55A CR Crawler Excavator Service Repair Manual

$34.00

Hyundai HX55A CR Crawler Excavator Service Repair Manual

$34.00 -

×

Hyundai R330LC-9A Crawler Excavator Service Repair Manual

$35.00

Hyundai R330LC-9A Crawler Excavator Service Repair Manual

$35.00 -

×

Hyundai HX160 L, HX180 L Crawler Excavator Service Repair Manual

$35.00

Hyundai HX160 L, HX180 L Crawler Excavator Service Repair Manual

$35.00 -

×

Hyundai HX300 L Crawler Excavator Service Repair Manual

$36.00

Hyundai HX300 L Crawler Excavator Service Repair Manual

$36.00 -

×

Hyundai HX500A L Crawler Excavator Service Repair Manual

$34.00

Hyundai HX500A L Crawler Excavator Service Repair Manual

$34.00 -

×

Hyundai HX35A Z Crawler Excavator Service Repair Manual

$34.00

Hyundai HX35A Z Crawler Excavator Service Repair Manual

$34.00 -

×

Hyundai R27Z-9 Crawler Excavator Service Repair Manual

$34.00

Hyundai R27Z-9 Crawler Excavator Service Repair Manual

$34.00 -

×

Hyundai HX480S L, HX520S L Crawler Excavator Service Repair Manual

$35.00

Hyundai HX480S L, HX520S L Crawler Excavator Service Repair Manual

$35.00 -

×

Hyundai R130S (Smart+) Crawler Excavator Service Repair Manual (Built in India)

$34.00

Hyundai R130S (Smart+) Crawler Excavator Service Repair Manual (Built in India)

$34.00 -

×

Hyundai R320LC-3 Crawler Excavator Service Repair Manual

$34.00

Hyundai R320LC-3 Crawler Excavator Service Repair Manual

$34.00 -

×

Hyundai HX17A Z Crawler Excavator Service Repair Manual

$34.00

Hyundai HX17A Z Crawler Excavator Service Repair Manual

$34.00 -

×

Hyundai R180LC-7 Crawler Excavator Service Repair Manual

$34.00

Hyundai R180LC-7 Crawler Excavator Service Repair Manual

$34.00 -

×

Hyundai HX300HD Crawler Excavator Service Repair Manual

$34.00

Hyundai HX300HD Crawler Excavator Service Repair Manual

$34.00 -

×

Hyundai R450LC-7 Crawler Excavator Service Repair Manual

$35.00

Hyundai R450LC-7 Crawler Excavator Service Repair Manual

$35.00 -

×

Hyundai HX300LT3 Crawler Excavator Service Repair Manual

$34.00

Hyundai HX300LT3 Crawler Excavator Service Repair Manual

$34.00 -

×

Hyundai HX430 L Crawler Excavator Service Repair Manual

$35.00

Hyundai HX430 L Crawler Excavator Service Repair Manual

$35.00 -

×

Hyundai R220LC-9S Crawler Excavator Service Repair Manual (Built in Brazil)

$35.00

Hyundai R220LC-9S Crawler Excavator Service Repair Manual (Built in Brazil)

$35.00 -

×

Hyundai HX260 L Crawler Excavator Service Repair Manual

$35.00

Hyundai HX260 L Crawler Excavator Service Repair Manual

$35.00 -

×

Hyundai R180LC-3 Crawler Excavator Service Repair Manual

$34.00

Hyundai R180LC-3 Crawler Excavator Service Repair Manual

$34.00 -

×

Hyundai R170W-7A Wheel Excavator Service Repair Manual

$35.00

Hyundai R170W-7A Wheel Excavator Service Repair Manual

$35.00 -

×

Hyundai R140LC-7 Crawler Excavator Service Repair Manual

$34.00

Hyundai R140LC-7 Crawler Excavator Service Repair Manual

$34.00 -

×

Hyundai R140LC-9V Crawler Excavator Service Repair Manual (Built in India)

$34.00

Hyundai R140LC-9V Crawler Excavator Service Repair Manual (Built in India)

$34.00 -

×

Hyundai R260LC-9S Crawler Excavator Service Repair Manual (Built in Brazil)

$34.00

Hyundai R260LC-9S Crawler Excavator Service Repair Manual (Built in Brazil)

$34.00 -

×

Hyundai R145CR-9 Crawler Excavator Service Repair Manual

$34.00

Hyundai R145CR-9 Crawler Excavator Service Repair Manual

$34.00 -

×

Hyundai R360LC-7 Crawler Excavator Service Repair Manual

$34.00

Hyundai R360LC-7 Crawler Excavator Service Repair Manual

$34.00 -

×

Hyundai HX1000L Crawler Excavator Service Repair Manual

$35.00

Hyundai HX1000L Crawler Excavator Service Repair Manual

$35.00 -

×

Hyundai R380LC-9SH Crawler Excavator Service Repair Manual

$35.00

Hyundai R380LC-9SH Crawler Excavator Service Repair Manual

$35.00 -

×

Hyundai R140W-7A Wheel Excavator Service Repair Manual

$35.00

Hyundai R140W-7A Wheel Excavator Service Repair Manual

$35.00 -

×

Hyundai R370LC-7 Crawler Excavator Service Repair Manual

$34.00

Hyundai R370LC-7 Crawler Excavator Service Repair Manual

$34.00 -

×

Hyundai R55-7A Crawler Excavator Service Repair Manual

$34.00

Hyundai R55-7A Crawler Excavator Service Repair Manual

$34.00 -

×

Hyundai R140W-7 Wheel Excavator Service Repair Manual

$35.00

Hyundai R140W-7 Wheel Excavator Service Repair Manual

$35.00 -

×

Hyundai R140LC-9A Crawler Excavator Service Repair Manual

$34.00

Hyundai R140LC-9A Crawler Excavator Service Repair Manual

$34.00 -

×

Hyundai R800LC-7A Crawler Excavator Service Repair Manual

$34.00

Hyundai R800LC-7A Crawler Excavator Service Repair Manual

$34.00 -

×

Hyundai R145CR-9A Crawler Excavator Service Repair Manual

$34.00

Hyundai R145CR-9A Crawler Excavator Service Repair Manual

$34.00 -

×

Hyundai R215 (Smart+) Crawler Excavator Service Repair Manual (Built in India)

$34.00

Hyundai R215 (Smart+) Crawler Excavator Service Repair Manual (Built in India)

$34.00 -

×

Hyundai R430LC-9 Crawler Excavator Service Repair Manual

$34.00

Hyundai R430LC-9 Crawler Excavator Service Repair Manual

$34.00 -

×

Hyundai R160LC-7 Crawler Excavator Service Repair Manual

$34.00

Hyundai R160LC-7 Crawler Excavator Service Repair Manual

$34.00 -

×

Hyundai R210-7V Crawler Excavator Service Repair Manual (Built in India)

$34.00

Hyundai R210-7V Crawler Excavator Service Repair Manual (Built in India)

$34.00 -

×

Hyundai R140W-9A Wheel Excavator Service Repair Manual

$34.00

Hyundai R140W-9A Wheel Excavator Service Repair Manual

$34.00 -

×

Hyundai R300LC-9SH Crawler Excavator Service Repair Manual

$35.00

Hyundai R300LC-9SH Crawler Excavator Service Repair Manual

$35.00 -

×

Hyundai R210NLC-7A Crawler Excavator Service Repair Manual

$34.00

Hyundai R210NLC-7A Crawler Excavator Service Repair Manual

$34.00 -

×

Hyundai R110-7A Crawler Excavator Service Repair Manual

$34.00

Hyundai R110-7A Crawler Excavator Service Repair Manual

$34.00

Hitachi ZX450-3, ZX470LCH-3 and ZX520LCH-3 Excavator Service Repair Manual

$38.00

This comprehensive service repair manual is specifically designed for the Hitachi Excavator models including:

- ZX450-3

- ZX450LC-3

- ZX470H-3

- ZX470LCH-3

- ZX500LC-3

- ZX520LCH-3

Format: PDF

Language: English

The manual provides detailed service and repair instructions.

Visit the link for complete information.

Hitachi ZX450-3, ZX470LCH-3, and ZX520LCH-3 Excavator Manual

Product Overview

This comprehensive service manual is specially crafted for Hitachi Excavators, covering models such as the ZX450-3, ZX450LC-3, ZX470H-3, ZX470LCH-3, ZX500LC-3, and ZX520LCH-3. Designed to offer valuable insights and instructions, this manual is essential for both operators and technicians who wish to fully understand their machinery. For more details, visit the Hitachi Excavator page.

Key Features

- Format: PDF

- Language: English

- Contains detailed service, operation, and workshop manuals

- Includes parts catalog and owner’s instructions

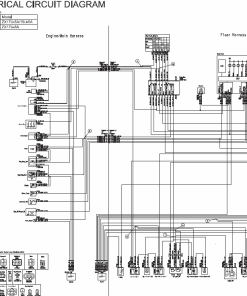

- Comprehensive circuit diagrams provided

Benefits

- Enhances your understanding of redelivery and delivery processes

- Assists with operational performance tests and troubleshooting

- Provides guidelines for safe machine maintenance and repairs

- Improves machine controllability through advanced hydraulic technologies

Usage Recommendations

- Utilize the service manual to ensure proper machine handling and safety precautions.

- Refer to the workshop manual for detailed maintenance standards and procedures.

- Employ the regenerative valve instructions to enhance cylinder speed and efficiency.

- Take advantage of the parts catalog for accurate and efficient part replacements.

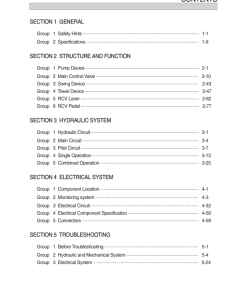

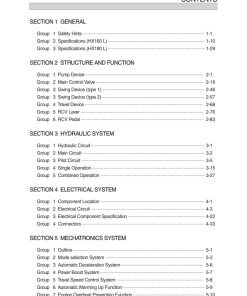

Manual Composition

The manual suite includes:

- Service Manual (Troubleshooting) – Vol. No. TO1J1-E: 586 Pages

- Service Manual (Operation) – Vol. No. TT1J1-E: 340 Pages

- Workshop Manual – Vol. No. W1J1-E: 578 Pages

- Parts Catalog Manual – P1J1-1-1: 429 Pages

- Owner’s Instructions: 383 Pages

- Circuit Diagram: 3 Pages

International System of Units (SI Units) is adopted throughout these manuals.

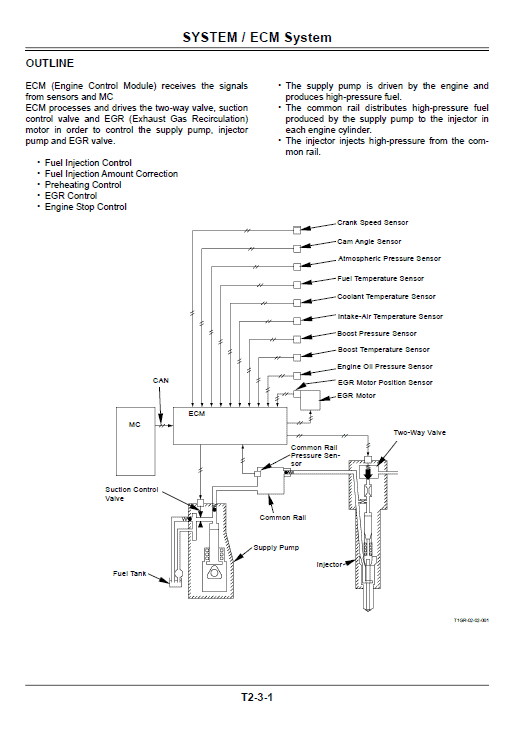

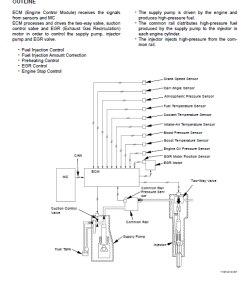

Advanced Features

Experience the advanced Hitachi ZAXIS technology, offering industry-leading hydraulic systems known for impressive fuel economy, swift movements, and easy operation. The new ZAXIS features exemplary fuel efficiency, high durability, and reduced running costs.

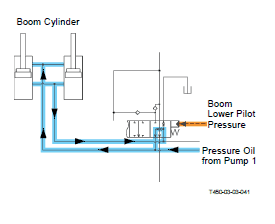

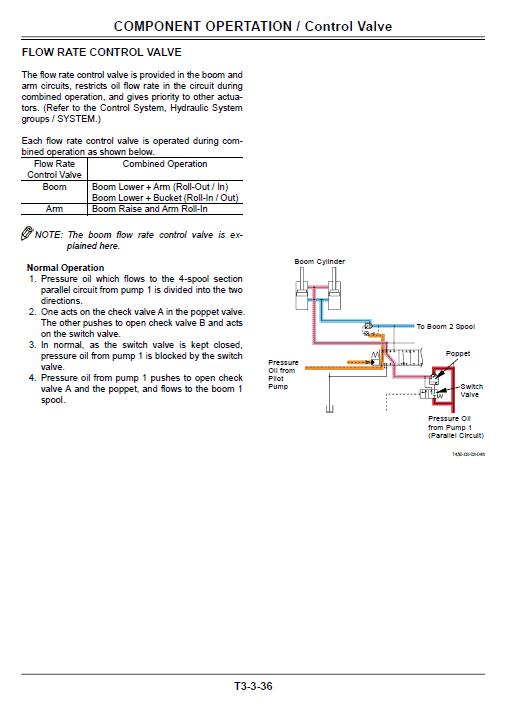

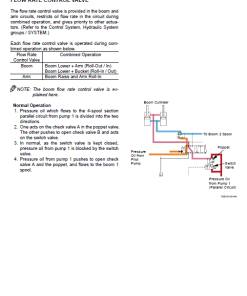

Regenerative Valve Functionality

The regenerative valve is integrated within the boom lower, arm roll-in, and bucket roll-in circuits to enhance cylinder speed and machine control. Hereu2019s how it operates:

- During the boom lowering process, return oil acts on the spool and check valve.

- The boom lowers quickly, utilizing its weight to reduce pressure between the pump and boom cylinder.

- When pressure on the cylinder rod side decreases, the check valve opens for regenerative operation.

- As full stroke is achieved or load increases, pressure dynamics change, closing the check valve to stop regeneration.

Only logged in customers who have purchased this product may leave a review.

Related products

$36.00

$49.00

$49.00

$48.00

$49.00

$44.00

$45.00

$48.00

Reviews

There are no reviews yet.