Hyundai R75-7 Mini Excavator Service Repair Manual

Product Overview

The Hyundai R75-7 Mini Excavator Service Repair Manual is an essential resource for service technicians engaged in the upkeep and repair of the Hyundai R75-7 model. It is designed to provide comprehensive guidance through detailed instructions and illustrations. Available in English, this PDF manual ensures that even the most intricate servicing tasks can be performed efficiently.

Mini Excavator Model: R75-7

Format: PDF

The manual is divided into several sections, each focusing on crucial aspects of the excavator’s components and systems, providing 149 pages dedicated to service and repair, complemented by a 91-page operators manual.

Key Features

- 149-page detailed service repair manual.

- 91-page operators manual with essential operating guidelines.

- Comprehensive section on hydraulic and electrical systems.

- Troubleshooting guidance for mechanical and electrical systems.

- Precise disassembly and assembly instructions.

- In-depth maintenance standards and performance testing guidelines.

Benefits

- Enhanced Repair Quality: Provides detailed insights to service technicians for accurate repairs.

- Comprehensive Guidance: Contains step-by-step instructions covering all major components.

- Increased Efficiency: Optimizes service operations in workshops with clear and concise instructions.

- Safety Assurance: Includes safety hints and specifications ensuring safe operations.

Usage Recommendations

- Familiarize with each section and group for effective understanding of repair processes.

- Consult the manual regularly during service and maintenance jobs to ensure accurate work.

- Use as a reference for trouble diagnosis and preventive maintenance strategies.

- Ideal for professional service workshops aiming to enhance repair quality and efficiency.

Additional Context

The Hyundai R75-7 manual is meticulously structured to assist service personnel in fully understanding the excavator’s functioning and maintenance. The detailed Table of Content spans sections covering the general layout, hydraulic and electrical systems, maintenance standards, and specific disassembly/assembly tasks, ensuring that personnel are well-informed about each component and its upkeep.

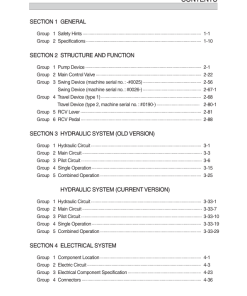

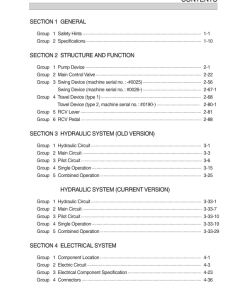

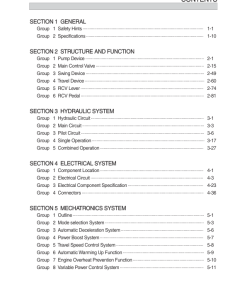

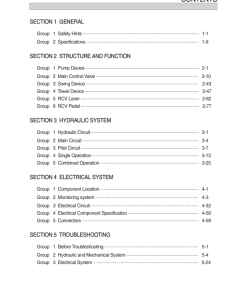

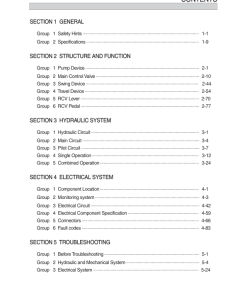

Table of Content

SECTION 1 GENERAL

Group 1 Safety Hints

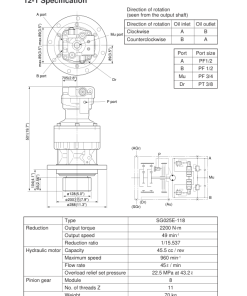

Group 2 Specifications

SECTION 2 STRUCTURE AND FUNCTION

Group 1 Pump Device

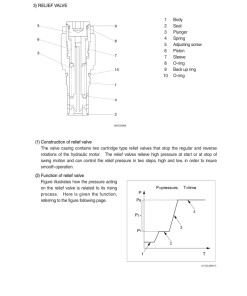

Group 2 Main Control Valve

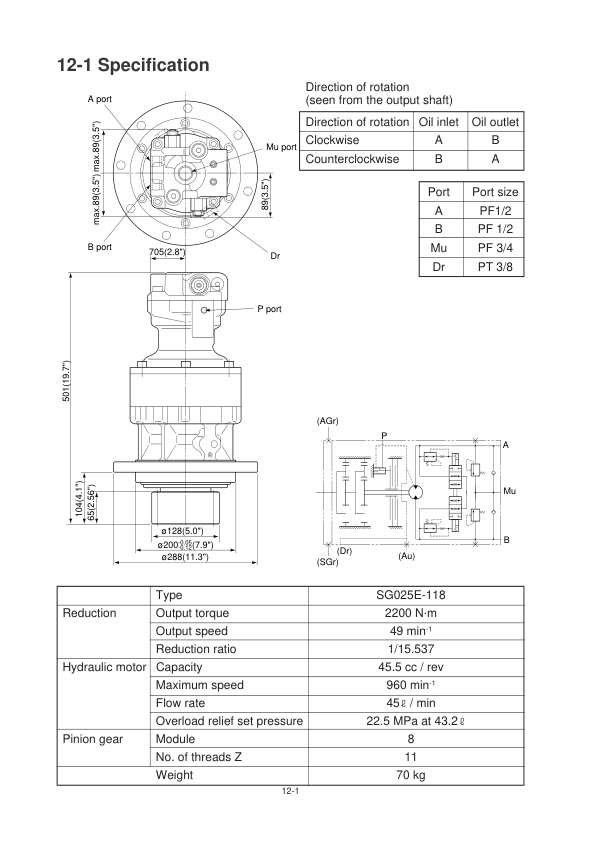

Group 3 Swing Device

Group 4 Travel Motor

Group 5 RCV Lever

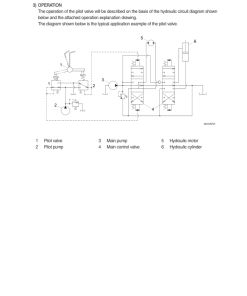

SECTION 3 HYDRAULIC SYSTEM

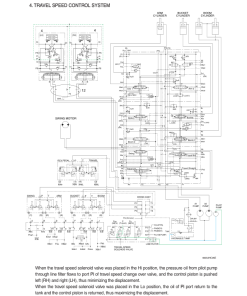

Group 1 Hydraulic Circuit

Group 2 Main Circuit

Group 3 Pilot Circuit

Group 4 Single Operation

Group 5 Combined Operation

SECTION 4 ELECTRICAL SYSTEM

Group 1 Component Location

Group 2 Monitoring System

Group 3 Electrical Circuit

Group 4 Electrical Component Specification

Group 5 Connectors

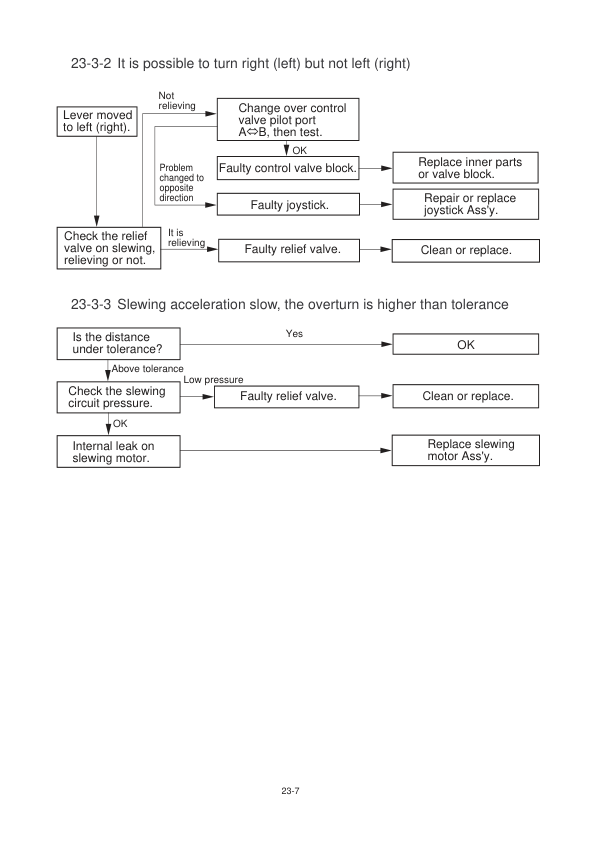

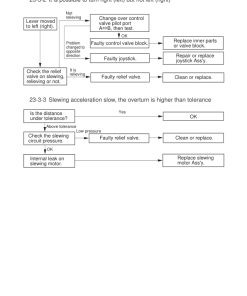

SECTION 5 TROUBLESHOOTING

Group 1 Before Troubleshooting

Group 2 Hydraulic and Mechanical System

Group 3 Electrical System

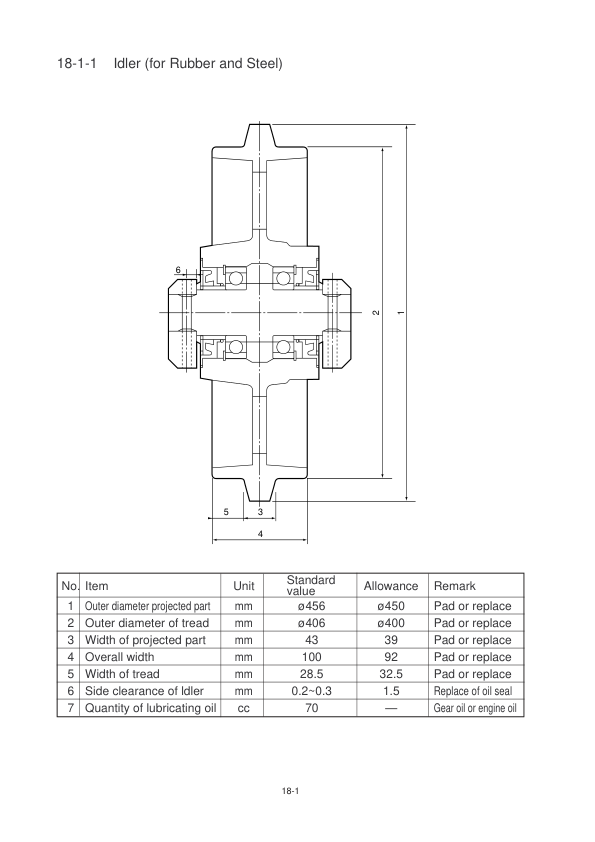

SECTION 6 MAINTENANCE STANDARD

Group 1 Operating Performance Test

Group 2 Major Components

Group 3 Track and Work Equipment

SECTION 7 DISASSEMBLY AND ASSEMBLY

Group 1 Precaution

Group 2 Tightening Torque

Group 3 Pump Device

Group 4 Main Control Valve

Group 5 Swing Device

Group 6 Travel Device

Group 7 RCV Lever

Group 8 Turning Joint

Group 9 Boom, Arm, Bucket Cylinder

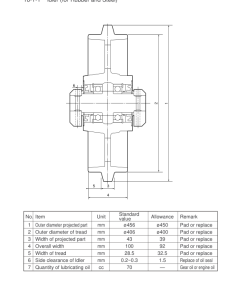

Group 10 Undercarriage

Group 11 Work Equipment

SECTION 8 COMPONENT MOUNTING TORQUE

Group 1 Introduction Guide

Group 2 Engine System

Group 3 Electric System

Group 4 Hydraulic System”, “

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.