John Deere 3215A, 3215B, 3225B, 3235A and 3235B Mower Technical Manual

$30.00

Explore the comprehensive John Deere Mower models 3215, 3215A, 3215B, 3225B, 3235, 3235A, and 3235B. This technical manual, available in English, offers a detailed guide with 492 pages of essential information. Downloadable in PDF format for ease of use.

John Deere 3215 Series Lightweight Fairway Mower Service Manual (TM1534)

Product Overview

The John Deere 3215 Series Lightweight Fairway Mower Service Manual (TM1534) is a comprehensive guide designed for the models 3215, 3215A, 3215B, 3225B, 3235, 3235A, and 3235B. This detailed service manual is available in PDF format and is written in English. It consists of 492 pages, providing essential repair, maintenance, and troubleshooting instructions for technicians.

- Model: John Deere Mower 3215, 3215A, 3215B, 3225B, 3235, 3235A, 3235B

- Language: English

- Format: PDF

Key Features

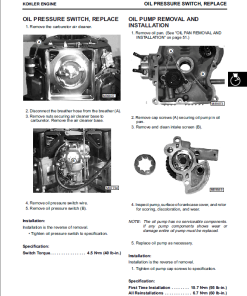

- Comprehensive repair and maintenance information.

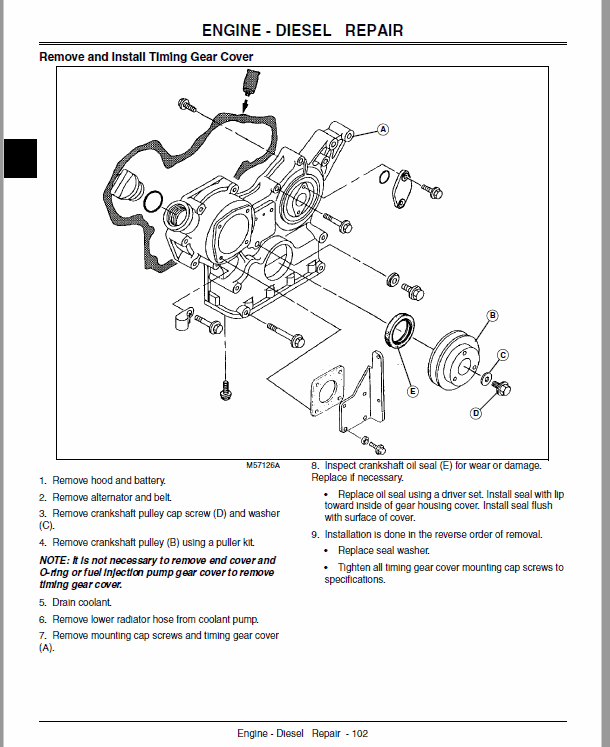

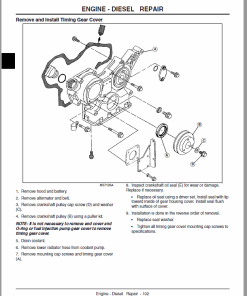

- Step-by-step installation instructions.

- Detailed troubleshooting procedures.

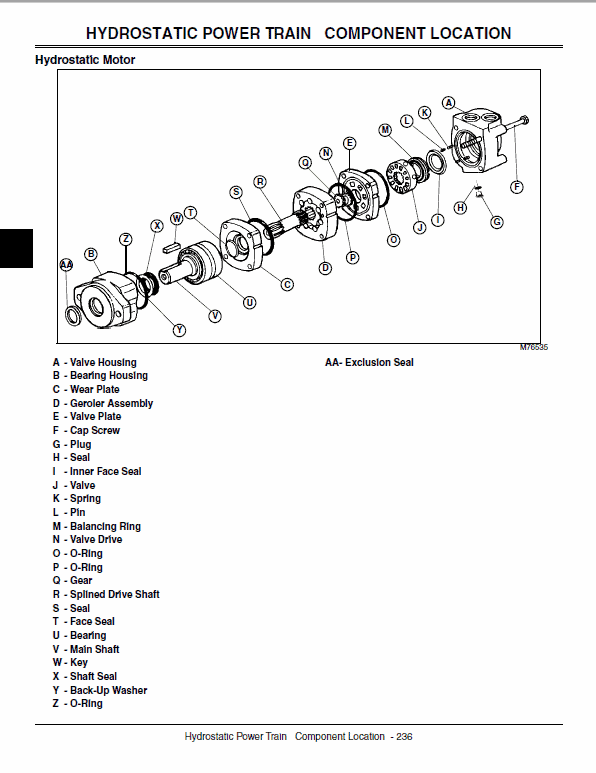

- High-quality illustrations including pictures and diagrams.

- Covers a range of models within the 3215 series.

Benefits

- Provides technicians with vital, on-the-job information.

- Facilitates understanding of complex machinery systems.

- Ensures efficient diagnosing and fixing of mower issues.

- Guides on correct installation and maintenance practices.

- Helps in identifying the installation location of spare parts.

Usage Recommendations

- Ideal for professional service technicians working on John Deere mowers.

- Useful for diagnosing steering and hydraulic system issues.

- Essential for accurately performing installation and maintenance tasks.

- Reference the manual for troubleshooting and testing procedures like steering system leakage tests.

- Use as a reference guide for correct torque specifications.

Contents of the Manual

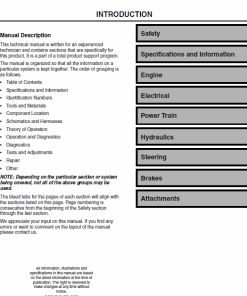

The manual includes sections on:

- Safety

- Specifications and Information

- Engine (Models 3TNE75-RJF and 3TNE78-JFM)

- Electrical

- Gear Power Train

- Steering and Brakes

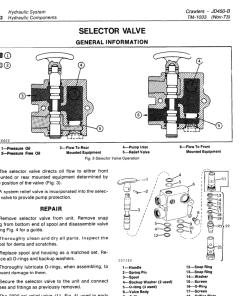

- Hydraulics

- Miscellaneous

For more detailed instructions and specifications, consider purchasing the John Deere 3235B manual.

Troubleshooting Example: Steering System

The manual includes a methodology for diagnosing issues such as steering wandering, involving steps to check tire pressures, air in the hydraulic system, tightness of hydraulic fittings, and condition of steering components. For comprehensive diagnostics, perform a steering system leakage test as guided in the manual.

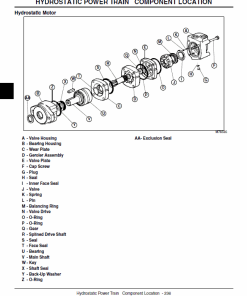

Installing Rear Wheel Motor (Four-Wheel Drive)

- Fit the hydrostatic motor into the rear axle housing.

- Ensure motor fittings are correctly positioned.

- Secure the motor with four bolts, tightening to specified torque.

- Connect hydraulic lines to the motor.

- Attach disk to motor shaft and secure with a nut, using proper tools.

- Fit the wheel and tire assembly.

- Test motor rotation for the correct direction. Adjust hydraulic lines if necessary.

Specifications for installation:

- Rear Axle Housing Bolt Torque: 140 Nm (105 lb-ft)

- Disc Torque: 190 Nm (140 lb-ft)

For purchasing, visit our Owl Store.

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.