Kawasaki 65ZV-2, 65TMV-2 Wheel Loader Service Manual

$31.00

Discover comprehensive manuals for the Kawasaki 65ZV-2, 65TMV-2 Wheel Loader. Available in English and PDF format, these manuals provide essential insights for maintenance and operation.

Kawasaki 65ZV-2, 65TMV-2 Wheel Loader Service Manual

Product Overview

The Kawasaki 65ZV-2, 65TMV-2 Wheel Loader Service Manual is an essential resource for operators and technicians. This comprehensive guide is available in English and comes in PDF format, providing detailed instructions for the maintenance, repair, and operation of these wheel loader models.

Manual Components:

- Repair Service Manual: 324 Pages

- Operating (Owners) Manual: 188 Pages

- Parts Catalog: 152 Pages

Manual Details

The manual offers thorough guidelines on maintenance and repair tasks to ensure the consistent and reliable performance of the Kawasaki 65ZV-2, 65TMV-2 Wheel Loader. Illustrated with up-to-date explanations, drawings, and photographs at the time of publication, this manual should be read thoroughly to guide systematic and logical repair work.

Key Features

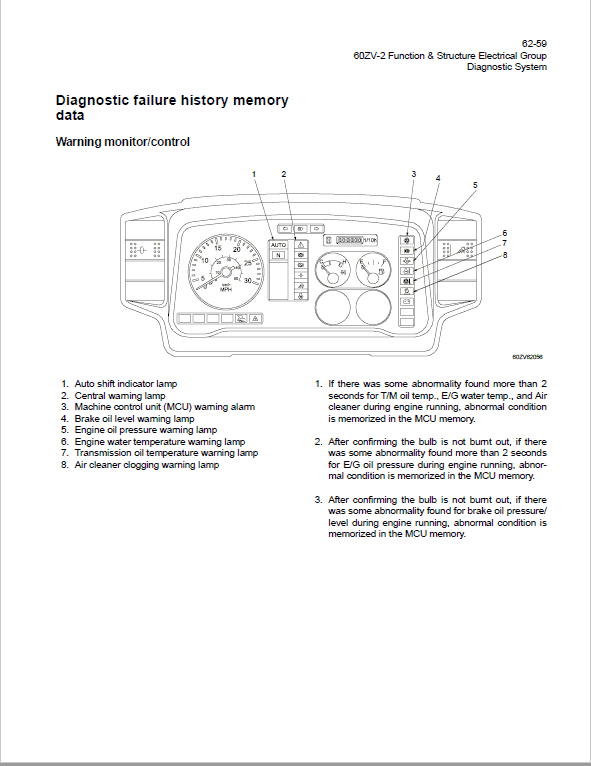

- General Outline: Overview of the loader’s features and specifications.

- Functions and Construction: Details on the mechanical structure and operational functions.

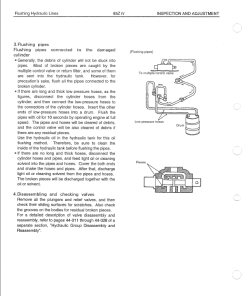

- Inspection and Adjustment: Instructions for regular checks and fine-tuning.

- Disassembly and Assembly: Step-by-step procedures for assembling and disassembling components.

- Maintenance Standards: Guidelines for maintaining high standards of safety and efficiency.

Critical maintenance operations, particularly those related to safety, are emphasized with a special marker in the manual.

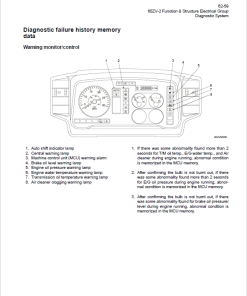

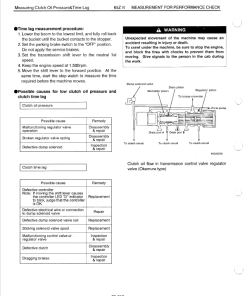

Manual Extract: Loading System

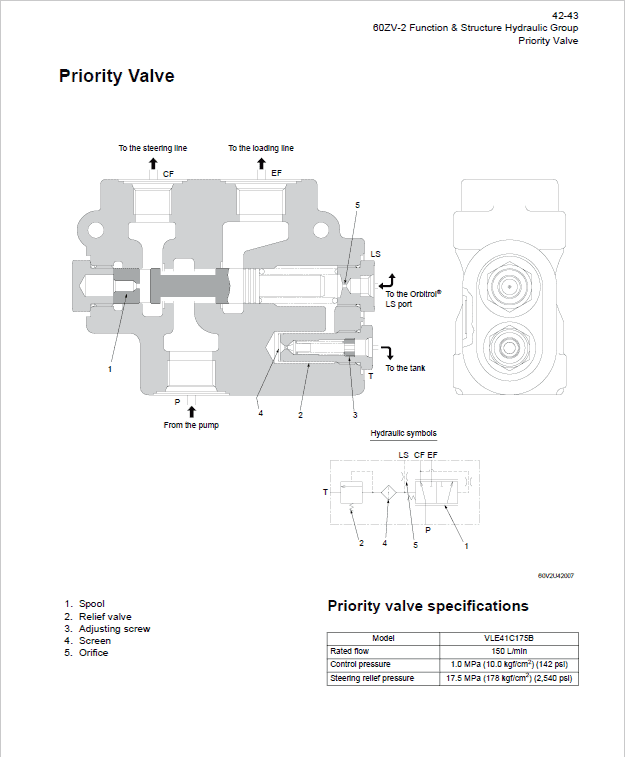

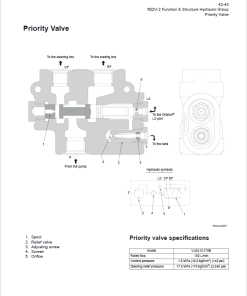

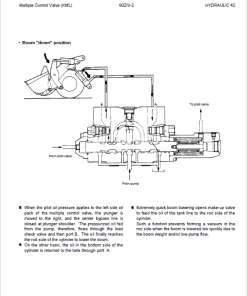

The loading system of the Kawasaki wheel loader features a pilot operation mechanism. It utilizes pilot valve pressure to manipulate the spool of the multiple control valve, effectively controlling the boom and bucket cylinders. Activation of the control lever opens the pilot valve line, generating oil pressure respective to the lever’s position.

Pressure adjustments are managed by the pilot valve, which moves the spool against its return spring based on the pressure applied. The loader pump directs oil through the valve to the cylinder, and return oil is channeled through the valve to the oil cooler, filter, and then into the tank. In emergencies, even if the hydraulic pump fails or the engine is off, the pressure in the pilot circuit’s accumulator allows the boom to be lowered safely.

Usage Recommendations

- Always read the manual thoroughly before beginning any maintenance or repair activities.

- Prioritize safety-related maintenance tasks as indicated in the manual.

- Use the manual as a reference for routine inspections and adjustments to prolong the machine’s lifespan.

Only logged in customers who have purchased this product may leave a review.

Kubota M100X, M110X, M126X, M135X Tractor Workshop Manual

Kubota M100X, M110X, M126X, M135X Tractor Workshop Manual

Reviews

There are no reviews yet.