-

×

Caterpillar CAT 745 Articulated Dump Truck Service Repair Manual (3T600001 and up)

$70.00

Caterpillar CAT 745 Articulated Dump Truck Service Repair Manual (3T600001 and up)

$70.00 -

×

Komatsu PC200-11E0 Excavator Service Repair Manual

$42.00

Komatsu PC200-11E0 Excavator Service Repair Manual

$42.00 -

×

Volvo Omni 1000 Screeds Repair Service Manual

$34.00

Volvo Omni 1000 Screeds Repair Service Manual

$34.00 -

×

Volvo VDT-V78 ETC Screeds Repair Service Manual

$36.00

Volvo VDT-V78 ETC Screeds Repair Service Manual

$36.00 -

×

Caterpillar CAT 320C, 320C L, 320C LN Excavator Service Repair Manual (DBG00001 and up)

$70.00

Caterpillar CAT 320C, 320C L, 320C LN Excavator Service Repair Manual (DBG00001 and up)

$70.00 -

×

Case 721D Loader Service Manual

$34.00

Case 721D Loader Service Manual

$34.00 -

×

Caterpillar CAT 303.5C CR Mini Hydraulic Excavator Service Repair Manual (DMY00001 and up)

$65.00

Caterpillar CAT 303.5C CR Mini Hydraulic Excavator Service Repair Manual (DMY00001 and up)

$65.00 -

×

Caterpillar CAT 320D2, 320D2 L Excavator Service Repair Manual (GBA00001 and up)

$70.00

Caterpillar CAT 320D2, 320D2 L Excavator Service Repair Manual (GBA00001 and up)

$70.00 -

×

Caterpillar CAT 305E Mini Hydraulic Excavator Service Repair Manual (XSC00001 and up)

$70.00

Caterpillar CAT 305E Mini Hydraulic Excavator Service Repair Manual (XSC00001 and up)

$70.00 -

×

Caterpillar CAT D400 Articulated Dump Truck Service Repair Manual (1MD00001 till 00246)

$70.00

Caterpillar CAT D400 Articulated Dump Truck Service Repair Manual (1MD00001 till 00246)

$70.00 -

×

Caterpillar CAT 225B Excavator Service Repair Manual

$70.00

Caterpillar CAT 225B Excavator Service Repair Manual

$70.00 -

×

Komatsu GD825A-2 Motor Grader Service Manual

$34.00

Komatsu GD825A-2 Motor Grader Service Manual

$34.00 -

×

Caterpillar CAT 320E RR, 320E LRR Excavator Service Repair Manual (LHN00001 and up)

$65.00

Caterpillar CAT 320E RR, 320E LRR Excavator Service Repair Manual (LHN00001 and up)

$65.00 -

×

Caterpillar CAT 305.5E Mini Hydraulic Excavator Service Repair Manual (FKY00001 and up)

$70.00

Caterpillar CAT 305.5E Mini Hydraulic Excavator Service Repair Manual (FKY00001 and up)

$70.00 -

×

John Deere 250D, 300D Series 2 Dump Truck Technical Manual (S.N. after E642001 - )

$61.00

John Deere 250D, 300D Series 2 Dump Truck Technical Manual (S.N. after E642001 - )

$61.00 -

×

Caterpillar CAT 320CU, 320CLU Excavator Service Repair Manual (CLM00001 and up)

$70.00

Caterpillar CAT 320CU, 320CLU Excavator Service Repair Manual (CLM00001 and up)

$70.00 -

×

John Deere E18ZS Excavator Repair Technical Manual (SN. D016000 - )

$30.00

John Deere E18ZS Excavator Repair Technical Manual (SN. D016000 - )

$30.00 -

×

Caterpillar CAT 311D LRR Excavator Service Repair Manual (DDW00001 and up)

$70.00

Caterpillar CAT 311D LRR Excavator Service Repair Manual (DDW00001 and up)

$70.00 -

×

Ford 501, 600, 601, 700, 701, 800, 801 Tractor Service Manual

$34.00

Ford 501, 600, 601, 700, 701, 800, 801 Tractor Service Manual

$34.00 -

×

Caterpillar CAT AE40 Underground Articulated Truck Service Repair Manual (1ZZ00001 and up)

$75.00

Caterpillar CAT AE40 Underground Articulated Truck Service Repair Manual (1ZZ00001 and up)

$75.00 -

×

Caterpillar CAT 245 Excavator Service Repair Manual (94L00255 and up)

$70.00

Caterpillar CAT 245 Excavator Service Repair Manual (94L00255 and up)

$70.00 -

×

Caterpillar CAT 304CR Mini Hydraulic Excavator Service Repair Manual (NAD00001 and up)

$70.00

Caterpillar CAT 304CR Mini Hydraulic Excavator Service Repair Manual (NAD00001 and up)

$70.00 -

×

Volvo Ultimat 200 Screeds Repair Service Manual

$34.00

Volvo Ultimat 200 Screeds Repair Service Manual

$34.00 -

×

Caterpillar CAT D400E II Articulated Dump Truck Service Repair Manual (APF00001 and up)

$70.00

Caterpillar CAT D400E II Articulated Dump Truck Service Repair Manual (APF00001 and up)

$70.00 -

×

Toyota 7HBW23 Powered Pallet Walkie Repair Service Manual

$30.00

Toyota 7HBW23 Powered Pallet Walkie Repair Service Manual

$30.00 -

×

Komatsu D61EX-24, D61PX-24 Dozer Service Manual

$36.00

Komatsu D61EX-24, D61PX-24 Dozer Service Manual

$36.00 -

×

Komatsu HM400-5 Dump Truck Service Manual

$37.00

Komatsu HM400-5 Dump Truck Service Manual

$37.00 -

×

Komatsu PC360LC-10, PC390LC-10 Excavator Service Manual

$36.00

Komatsu PC360LC-10, PC390LC-10 Excavator Service Manual

$36.00 -

×

Caterpillar CAT 320D, 320D L Excavator Service Repair Manual (KGF00001 and up)

$70.00

Caterpillar CAT 320D, 320D L Excavator Service Repair Manual (KGF00001 and up)

$70.00 -

×

Toyota 2TG20, 02-2TD20, 2TG20, 02-2TG20, 42-2TD20 Towing Tractor Repair Manual

$36.00

Toyota 2TG20, 02-2TD20, 2TG20, 02-2TG20, 42-2TD20 Towing Tractor Repair Manual

$36.00 -

×

Case CX470B Crawler Excavator Service Manual

$35.00

Case CX470B Crawler Excavator Service Manual

$35.00 -

×

Toyota 7FDU35, 7FDU45, 7FDU60, 7FDU70, 7FDU80, 7FDKU40, 7FDAU50 Forklift Repair Manual

$35.00

Toyota 7FDU35, 7FDU45, 7FDU60, 7FDU70, 7FDU80, 7FDKU40, 7FDAU50 Forklift Repair Manual

$35.00 -

×

Komatsu PC270LC-7L Excavator Service Manual

$34.00

Komatsu PC270LC-7L Excavator Service Manual

$34.00 -

×

Caterpillar CAT 321D LCR Excavator Service Repair Manual (KBZ00001 and up)

$70.00

Caterpillar CAT 321D LCR Excavator Service Repair Manual (KBZ00001 and up)

$70.00 -

×

Ford 7840, 8240, 8340 Tractor Service Manual

$36.00

Ford 7840, 8240, 8340 Tractor Service Manual

$36.00 -

×

Komatsu PC400-8, PC400LC-8 Excavator Service Manual

$35.00

Komatsu PC400-8, PC400LC-8 Excavator Service Manual

$35.00 -

×

Caterpillar CAT 316F L Excavator Service Repair Manual (ECZ00001 and up)

$80.00

Caterpillar CAT 316F L Excavator Service Repair Manual (ECZ00001 and up)

$80.00 -

×

Caterpillar CAT 730 Articulated Dump Truck Service Repair Manual (3T300001 and up)

$70.00

Caterpillar CAT 730 Articulated Dump Truck Service Repair Manual (3T300001 and up)

$70.00 -

×

Caterpillar CAT 730 Articulated Dump Truck Service Repair Manual (B1M00001 and up)

$70.00

Caterpillar CAT 730 Articulated Dump Truck Service Repair Manual (B1M00001 and up)

$70.00 -

×

Caterpillar CAT AD60 Underground Articulated Truck Service Repair Manual (NNW00001 and up)

$70.00

Caterpillar CAT AD60 Underground Articulated Truck Service Repair Manual (NNW00001 and up)

$70.00 -

×

Caterpillar CAT 304.5 Mini Hydraulic Excavator Service Repair Manual (WAK00001 and up)

$70.00

Caterpillar CAT 304.5 Mini Hydraulic Excavator Service Repair Manual (WAK00001 and up)

$70.00 -

×

Volvo VDT121 Vario Screeds Repair Service Manual

$21.00

Volvo VDT121 Vario Screeds Repair Service Manual

$21.00 -

×

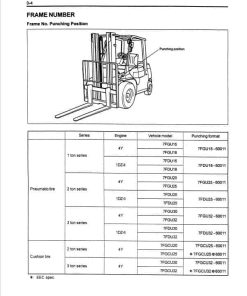

TOYOTA 7FGU15, 7FGU18, 7FGU20, 7FGU25, 7FGU30, 7FGU32 Forklift Repair Manual

$30.00

TOYOTA 7FGU15, 7FGU18, 7FGU20, 7FGU25, 7FGU30, 7FGU32 Forklift Repair Manual

$30.00 -

×

Caterpillar CAT 313D2, 313D2 GC Excavator Service Repair Manual (FAP00001 and up)

$80.00

Caterpillar CAT 313D2, 313D2 GC Excavator Service Repair Manual (FAP00001 and up)

$80.00 -

×

Case CX350 Excavator Service Manual

$34.00

Case CX350 Excavator Service Manual

$34.00 -

×

Caterpillar CAT 304.5E Mini Hydraulic Excavator Service Repair Manual (FXT00001 and up)

$70.00

Caterpillar CAT 304.5E Mini Hydraulic Excavator Service Repair Manual (FXT00001 and up)

$70.00 -

×

Toyota 6HBW23 Powered Pallet Walkie Service Repair Manual

$31.00

Toyota 6HBW23 Powered Pallet Walkie Service Repair Manual

$31.00 -

×

Caterpillar CAT 313D2 LGP Excavator Service Repair Manual (GAJ00001 and up)

$80.00

Caterpillar CAT 313D2 LGP Excavator Service Repair Manual (GAJ00001 and up)

$80.00 -

×

Ford CL-25 Compact Loader Service Manual

$31.00

Ford CL-25 Compact Loader Service Manual

$31.00 -

×

Komatsu WA75-3 Wheel Loader Service Manual

$36.00

Komatsu WA75-3 Wheel Loader Service Manual

$36.00 -

×

Komatsu WA900-3, WA900-3E0 Wheel Loader Service Manual

$35.00

Komatsu WA900-3, WA900-3E0 Wheel Loader Service Manual

$35.00 -

×

Caterpillar CAT 301.7D Mini Hydraulic Excavator Service Repair Manual (LJ400001 and up)

$70.00

Caterpillar CAT 301.7D Mini Hydraulic Excavator Service Repair Manual (LJ400001 and up)

$70.00 -

×

Komatsu Wabco 170D Haulpak Truck Service Repair Manual

$40.00

Komatsu Wabco 170D Haulpak Truck Service Repair Manual

$40.00

Kawasaki 90ZV-2 Wheel Loader Service Manual

$36.00

Explore comprehensive guides for the Kawasaki 90ZV-2 Wheel Loader.

Language: English

Format: PDF

SKU: 533282

Category: Kawasaki

Kawasaki 90ZV-2 Wheel Loader Service Manual

Product Overview

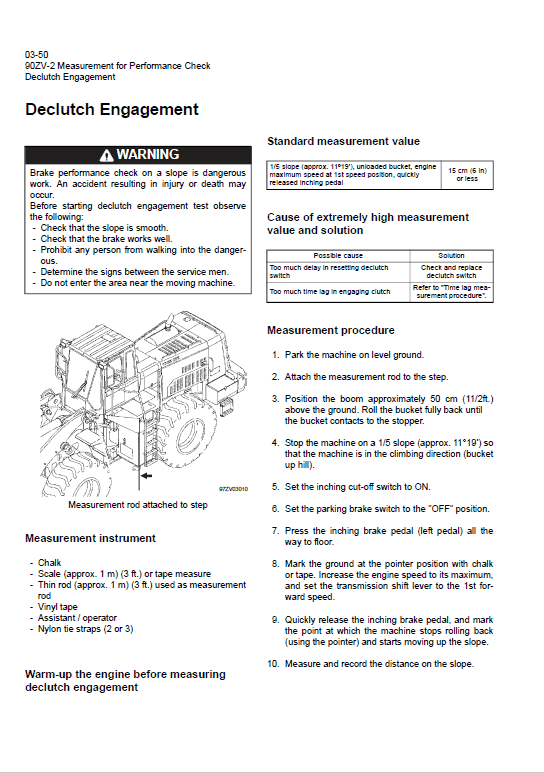

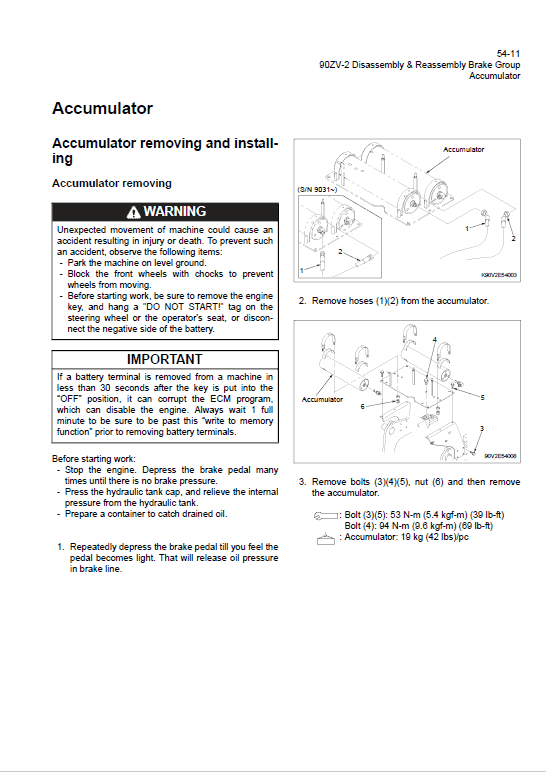

The Kawasaki 90ZV-2 Wheel Loader Service Manual is an essential resource for owners and operators of the 90ZV-2 machinery. This comprehensive manual is provided in PDF format and is available in English. It includes a detailed repair service manual spanning 1011 pages, an operating manual of 230 pages, and a parts catalog with 684 pages.

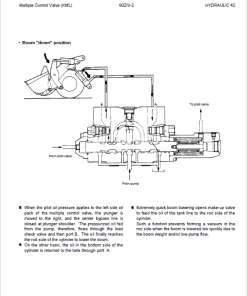

Manual Details

This manual offers extensive guidelines for the repair and maintenance of the Kawasaki 90ZV-2 Wheel Loader. It combines up-to-date explanations, illustrations, and photographs to provide a thorough understanding of the requirements for maintaining this machinery. Properly following the manual’s guidance will ensure your loader performs reliably over its lifespan.

Content Breakdown

- General Outline

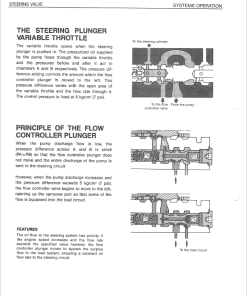

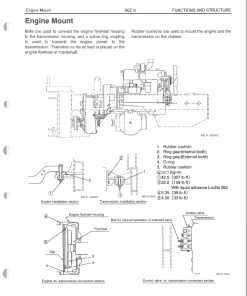

- Functions and Construction

- Inspection and Adjustment

- Disassembly and Assembly

- Maintenance Standards

Safety is paramount, and the manual highlights significant safety-related maintenance operations with a marked annotation.

Key Features

- Detailed 1011-page service manual for in-depth repairs.

- 230-page operating manual for daily operational guidance.

- 684-page parts catalog for easy identification of components.

- Structured information with annotated safety points.

Benefits

- Ensures efficient and effective maintenance practices.

- Supports long-term reliable performance of the loader.

- Enhances safety procedures during repair and maintenance.

- Facilitates quick part sourcing and component understanding.

Usage Recommendations

- Thoroughly read and understand the manual before performing any maintenance tasks.

- Follow systematic and logical steps as outlined in the manual for repairs.

- Pay close attention to safety sections marked with a special annotation.

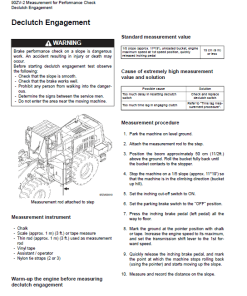

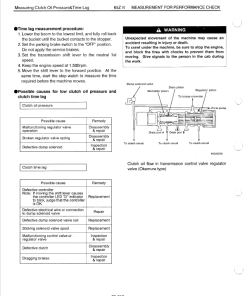

Example Task: Measuring Loading Circuit Main Relief Pressure

Step-by-step instructions:

- Unload the bucket.

- Press the brake pedal and ensure the transmission shift lever is in the neutral position.

- Set the parking brake switch to the “ON” position.

- Depress the brake pedal and lower the boom to its lowest limit.

- Attach a pressure gauge (30 MPa or 5,000 psi) to the bottom side of the bucket cylinder.

- Move the bucket control lever to the roll-back position and hold it there.

- Increase the engine speed to maximum, then measure and record the pressure.

- Adjust pressure if needed by turning the adjusting screw clockwise to raise pressure or counterclockwise to lower it.

Only logged in customers who have purchased this product may leave a review.

Related products

$36.00

$34.00

$36.00

$35.00

$32.00

$36.00

$36.00

$33.00

Reviews

There are no reviews yet.