-

×

Caterpillar CAT CB-334E, CB-335E Vibratory Compactor Service Repair Manual (C5F00001 and up)

$50.00

Caterpillar CAT CB-334E, CB-335E Vibratory Compactor Service Repair Manual (C5F00001 and up)

$50.00 -

×

Case 9110, 9130, 9150, 9170, 9180 Tractor Service Manual

$34.00

Case 9110, 9130, 9150, 9170, 9180 Tractor Service Manual

$34.00 -

×

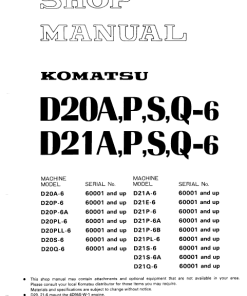

Komatsu D31E-20, D31P-20, D31PL-20, D31PLL-20 Dozer Manual

$34.00

Komatsu D31E-20, D31P-20, D31PL-20, D31PLL-20 Dozer Manual

$34.00 -

×

Liebherr Diesel Engine D9306 9308 9406 9408 Service Manual TM-1831 & TM-2224

$32.00

Liebherr Diesel Engine D9306 9308 9406 9408 Service Manual TM-1831 & TM-2224

$32.00 -

×

Kawasaki 65ZIII Wheel Loader Service Manual

$34.00

Kawasaki 65ZIII Wheel Loader Service Manual

$34.00 -

×

Case 21E, 121E, 221E, 321E Series 3 Wheel Loaders Service Manual

$34.00

Case 21E, 121E, 221E, 321E Series 3 Wheel Loaders Service Manual

$34.00 -

×

Hitachi ZX55U-5B Mini Excavator Service Repair Manual

$45.00

Hitachi ZX55U-5B Mini Excavator Service Repair Manual

$45.00 -

×

Kawasaki KSS70, 70ZII Wheel Loader Service Manual

$34.00

Kawasaki KSS70, 70ZII Wheel Loader Service Manual

$34.00 -

×

Case Farmall 80N, 90N, 100N, 110N Tractor Service Manual

$37.00

Case Farmall 80N, 90N, 100N, 110N Tractor Service Manual

$37.00 -

×

Caterpillar CAT D6N Track-Type Tractor Service Repair Manual (GHS00001 and up)

$70.00

Caterpillar CAT D6N Track-Type Tractor Service Repair Manual (GHS00001 and up)

$70.00 -

×

New Holland E385B, E385BLC Excavator Service Manual

$34.00

New Holland E385B, E385BLC Excavator Service Manual

$34.00 -

×

New Holland E385C Crawler Excavator Service Manual

$34.00

New Holland E385C Crawler Excavator Service Manual

$34.00

Komatsu CK25-1 Skid-Steer Loader Service Manual

$32.00

Manual Details:

- Pages: 306

Specifications:

SKU: 397219

Categories: Komatsu, Skid-Steer

CK25-1 Shop Manual

Product Overview

The CK25-1 Shop Manual is a comprehensive guide designed to enhance the quality of repairs by providing clear and accurate technical information. This manual helps operators understand the product thoroughly and informs them of the correct procedures for performing repairs and making sound judgments. It is an essential tool for any service workshop, offering detailed information on various component operations.

Key Features

- Detailed Chapters: The manual is organized into chapters that focus on each major component group, ensuring easy navigation and targeted information.

- Technical Precision: Provides the necessary technical information required for workshop operations, enhancing professional repair work.

- Troubleshooting Guides: Includes troubleshooting charts that correlate problems to potential causes.

Benefits

- Enhanced Repair Quality: Gain a deeper understanding of component structure and function, leading to more effective troubleshooting and repairs.

- Improved Safety and Efficiency: Follow tested procedures for removal, installation, and adjustments to ensure operations are conducted safely and efficiently.

- Comprehensive Maintenance Information: Assess disassembled parts with clear maintenance standards, ensuring parts meet operational criteria.

Usage Recommendations

- Ensure complete understanding of the manual to effectively utilize its content during repairs.

- Refer to the Structure and Function section to familiarize yourself with the components and use it as a reference for troubleshooting.

- Perform checks outlined in the Testing and Adjustments section before and after repairs to verify functionality.

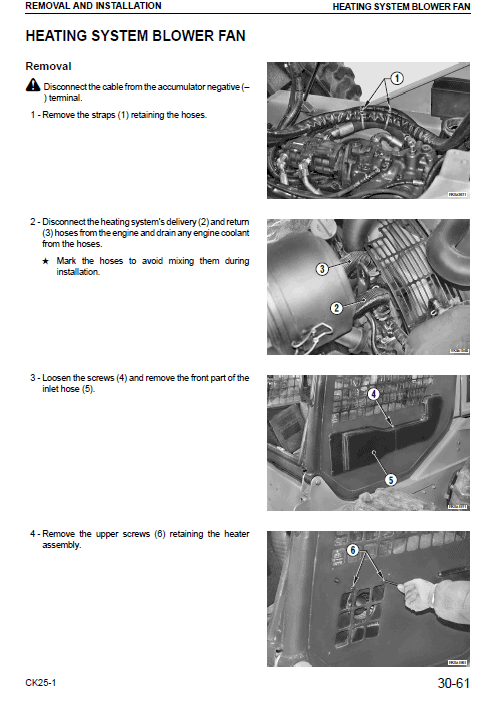

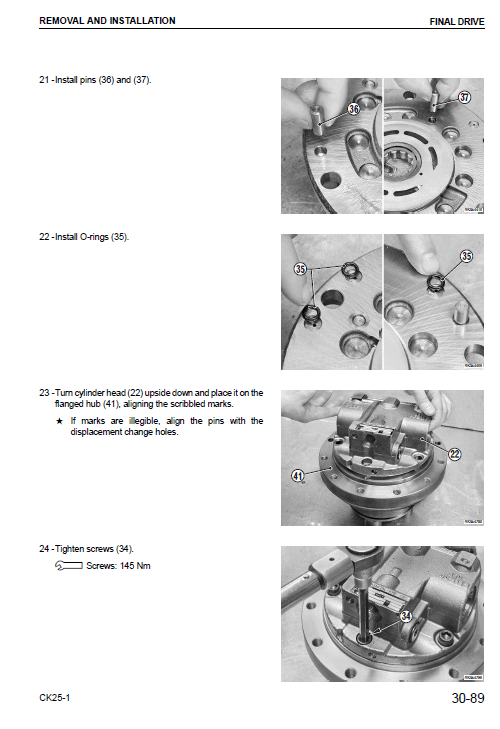

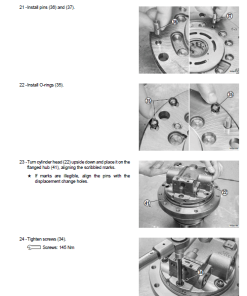

- Follow step-by-step guidance in the Removal and Installation section to execute these tasks accurately and safely.

Chapter Overview

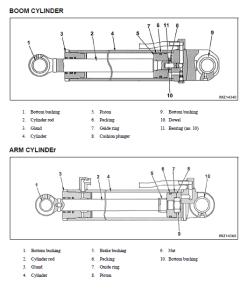

- Structure and Function: Details the construction and role of each component, critical for understanding the systems and effective troubleshooting.

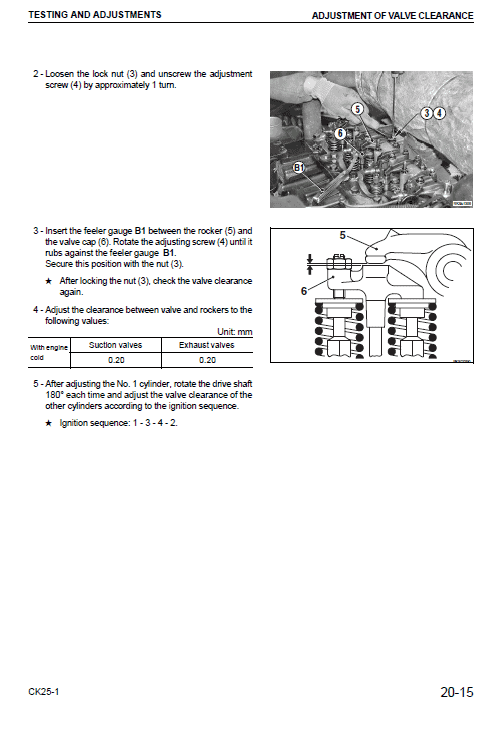

- Testing and Adjustments: Outlines necessary checks and adjustments before and after repairs, including detailed troubleshooting charts.

- Removal and Installation: Provides a sequence of operations for the safe and precise removal, disassembly, assembly, and installation of components.

- Standard Maintenance: Offers standards for inspection of disassembled parts, ensuring they meet quality and safety requirements.

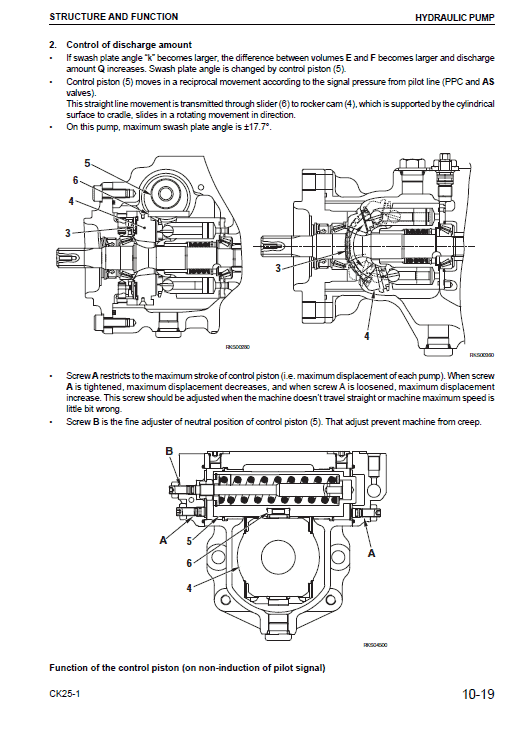

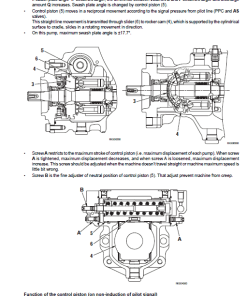

Testing the Hydraulic Pump

- Check the working pressure of the travel circuit HST charge valve with the machine raised from the ground.

- Engine: High idling

- Oil temperature: 45u201355u00b0C

- Safety bar: Raised

- Do not activate the travel lever.

- Remove the plugs (1) and (2) and mount the two pressure adapters E5.

- Connect two pressure gauges E1 (60 bar), start the engine, and accelerate to high idling.

Only logged in customers who have purchased this product may leave a review.

Related products

$32.50

$33.00

$34.00

$34.00

Reviews

There are no reviews yet.