-

×

Bobcat 2000 Loader Service Manual

$32.00

Bobcat 2000 Loader Service Manual

$32.00 -

×

Bobcat T250 Loader Service Manual

$35.00

Bobcat T250 Loader Service Manual

$35.00 -

×

Bobcat T770 Loader Service Manual

$36.00

Bobcat T770 Loader Service Manual

$36.00 -

×

Tigercat 250B Loader Repair Service Manual (2500501 - 2502000)

$34.00

Tigercat 250B Loader Repair Service Manual (2500501 - 2502000)

$34.00 -

×

Cummins ISB and QSB5.9 Engines Shop Service Manual

$25.00

Cummins ISB and QSB5.9 Engines Shop Service Manual

$25.00 -

×

Bobcat T250 Turbo and Turbo High Flow Track Loader Service Manual

$35.00

Bobcat T250 Turbo and Turbo High Flow Track Loader Service Manual

$35.00 -

×

Tigercat 2160 Loader Forwarder Repair Service Manual (21600101 - 21600500)

$40.00

Tigercat 2160 Loader Forwarder Repair Service Manual (21600101 - 21600500)

$40.00 -

×

AGCO Sisu Power 33, 44, 49, 66, 74, 84,98 (4th Generation) Engine Manual

$24.00

AGCO Sisu Power 33, 44, 49, 66, 74, 84,98 (4th Generation) Engine Manual

$24.00 -

×

Tigercat 234B Loader Repair Service Manual

$40.00

Tigercat 234B Loader Repair Service Manual

$40.00 -

×

Cummins ISB, ISC, ISL, ISLe, ISDe, and QSB3.3 Engines Repair Manual

$37.00

Cummins ISB, ISC, ISL, ISLe, ISDe, and QSB3.3 Engines Repair Manual

$37.00 -

×

Bobcat B700 Loader Service Repair Manual

$38.00

Bobcat B700 Loader Service Repair Manual

$38.00 -

×

Bobcat 2400 Loader Service Manual

$35.00

Bobcat 2400 Loader Service Manual

$35.00 -

×

Bobcat BL370 (B-Series) Loader Service Repair Manual

$38.00

Bobcat BL370 (B-Series) Loader Service Repair Manual

$38.00 -

×

JCB SD70, SD80 Steer Drive Axles Service Repair Manual

$21.00

JCB SD70, SD80 Steer Drive Axles Service Repair Manual

$21.00 -

×

Bobcat T450 Compact Track Loader Service Repair Manual

$36.00

Bobcat T450 Compact Track Loader Service Repair Manual

$36.00 -

×

Bobcat B780 Loader Service Repair Manual

$38.00

Bobcat B780 Loader Service Repair Manual

$38.00 -

×

Kohler Diesel KDI 1903 TCR and KDI 2504 TCR Engine Service Repair Manual

$26.00

Kohler Diesel KDI 1903 TCR and KDI 2504 TCR Engine Service Repair Manual

$26.00 -

×

Tigercat T234B Loader Repair Service Manual (234T7000 - 234T8100)

$37.00

Tigercat T234B Loader Repair Service Manual (234T7000 - 234T8100)

$37.00 -

×

Sisudielsel 320, 420, 620, 634 Engines Workshop Service Manual

$25.00

Sisudielsel 320, 420, 620, 634 Engines Workshop Service Manual

$25.00 -

×

Bobcat BL470, BL475 Loader Service Repair Manual

$38.00

Bobcat BL470, BL475 Loader Service Repair Manual

$38.00 -

×

Bobcat T650 Loader Repair Service Manual

$35.00

Bobcat T650 Loader Repair Service Manual

$35.00 -

×

Tigercat 250 Loader Repair Service Manual (2500101 - 2500499)

$34.00

Tigercat 250 Loader Repair Service Manual (2500101 - 2500499)

$34.00 -

×

Bobcat T750 Loader Service Manual

$36.00

Bobcat T750 Loader Service Manual

$36.00 -

×

Kohler Diesel KDI 1903 M and KDI 2504 M Engine Service Manual

$25.00

Kohler Diesel KDI 1903 M and KDI 2504 M Engine Service Manual

$25.00 -

×

Scania DC16, DI16 16-litre Engine Workshop Service Manual

$25.00

Scania DC16, DI16 16-litre Engine Workshop Service Manual

$25.00 -

×

Timberjack 933D Clambunk Service Repair Manual (933191 and up)

$39.00

Timberjack 933D Clambunk Service Repair Manual (933191 and up)

$39.00 -

×

Bobcat T320 Loader Service Manual

$35.00

Bobcat T320 Loader Service Manual

$35.00 -

×

JCB AGCO OEM Transmission ML180 T702 Manual

$30.00

JCB AGCO OEM Transmission ML180 T702 Manual

$30.00 -

×

John Deere 2954D Road Builder Repair Technical Manual (TM10406)

$34.00

John Deere 2954D Road Builder Repair Technical Manual (TM10406)

$34.00 -

×

Timberjack 608 Carriers Service Repair Manual (977031 - 987326)

$39.00

Timberjack 608 Carriers Service Repair Manual (977031 - 987326)

$39.00

Comprehensive Shop Manual for Machinery Maintenance

Product Overview

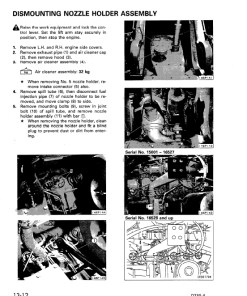

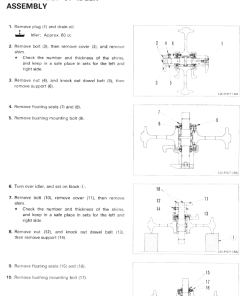

This detailed shop manual provides invaluable insights into various components of your machinery. Structured into easily navigable sections, it covers everything from specifications and tools to assembly tips and service bulletins. Each section is carefully indexed, ensuring quick and efficient access to the information you need.

Key Features

- Comprehensive section on specifications, pressures, and tolerances for different components.

- Guidelines on service/special tools necessary for maintenance.

- Detailed instructions on lubricants and sealants usage.

- Special torques, tests, and adjustments instructions for optimal machinery performance.

Benefits

- Helps reduce downtime by providing clear maintenance protocols.

- Ensures proper and efficient machinery operation through structured guidelines.

- Facilitates troubleshooting with dedicated sections on common components.

- Enhances longevity of machinery by recommending appropriate tools and techniques.

Sections Included

- Introduction – Specifications and tool requirements.

- Cooling System – Section 6.

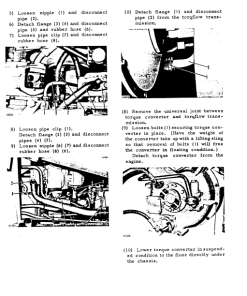

- Drive Train – Section 7, including Torque Converter and Transmission subsections.

- Steering and Sprocket Drive – Sections 7E and 7F.

- Electrical Components – Section 8.

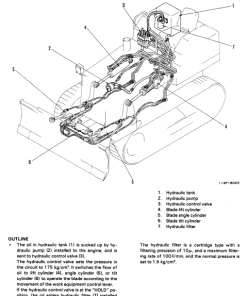

- Hydraulics – Section 10 with detailed pump and motor guidance.

- Power Systems – Section 12.

- Undercarriage and Track Chains – Sections 14 and 15.

- Mounted Equipment – Section 17.

Usage Recommendations

- For ease of use, locate the needed section via the index tabs and proceed directly to that section.

- Utilize the manual to perform routine checks as outlined, focusing on tolerances and pressures.

- Follow assembly tips and service bulletins for efficient problem-solving.

- Use as a guide when conducting inspections and using specified tools for maintenance tasks.

Structure, Function & Maintenance Standards

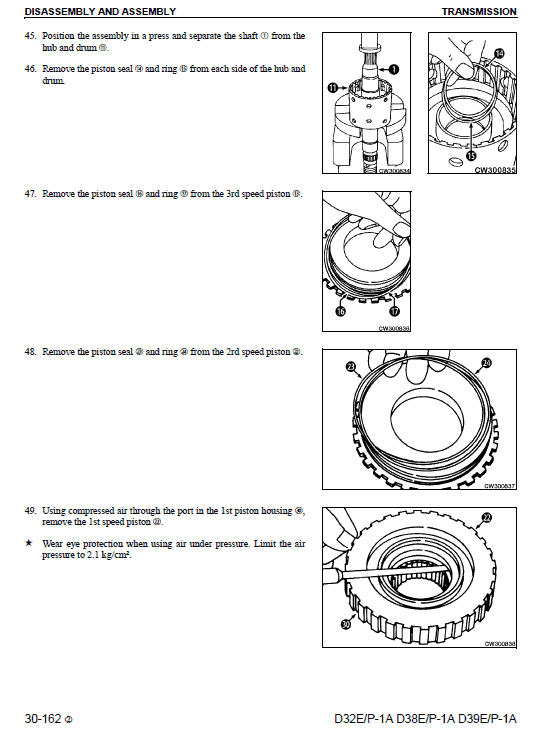

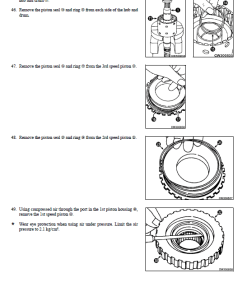

The transmission system, designed for optimal performance, offers three forward and three reverse speeds. Key components include directional, range, counter, and reverse idler shafts. The system channels power through these elements to propel the machinery.

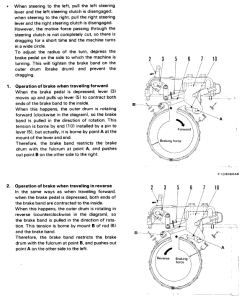

In steering drives, power transitions from the bevel gear and carrier assembly through clutch and brake discs to the final drive and sprockets, then onto the tracks. The sophisticated system of clutch disc engagement ensures efficient power transfer and maneuverability, even during turns.

Only logged in customers who have purchased this product may leave a review.

Related products

$32.50

$33.50

$34.00

$27.50

$34.00

Reviews

There are no reviews yet.