Komatsu D355-A1 Dozer Service Manual

$29.00

This comprehensive Komatsu D355-A1 Dozer shop manual is a must-have for maintenance and operation guidance.

Torque Converter Assembly Manual

Product Overview

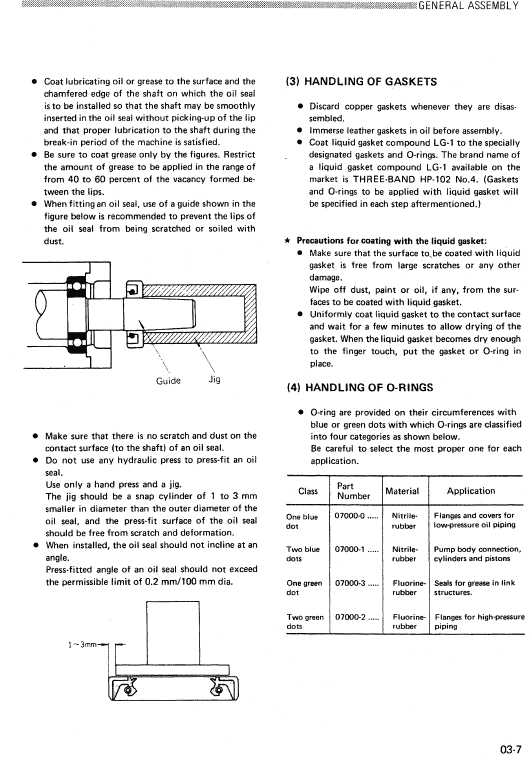

This manual provides comprehensive guidance for the assembly, disassembly, and maintenance of various components of the machinery, including the Torque Converter Assembly. Designed to assist technicians and engineers, it ensures you execute maintenance operations efficiently and safely.

Table of Contents

- General Overview – Introduction to key operations and machinery specifications.

- General Disassembly – Step-by-step guide to safely dismantle machinery components.

- General Assembly – Instructions for reassembling machinery parts effectively.

- Adjustment Inspections – Inspections required after general assembly to ensure precision.

- Radiator Fan – Details pertaining to the radiator fan inspection and maintenance.

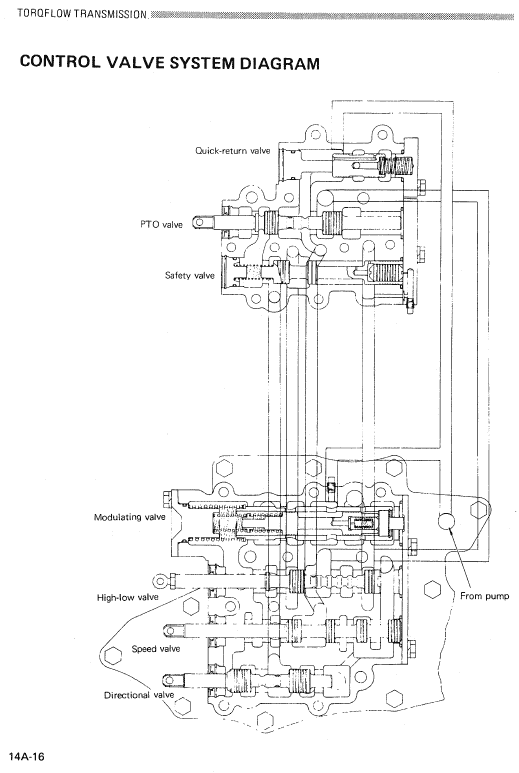

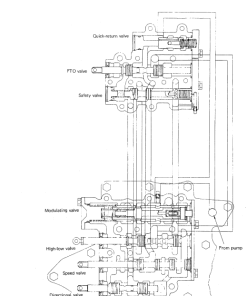

- PTO – Power Take-Off mechanism insights and troubleshooting tips.

- Torque Converter – Specific guidance on managing the torque converter assembly.

- Torqflow Transmission – Procedures for disassembly, assembly, and maintenance tactics.

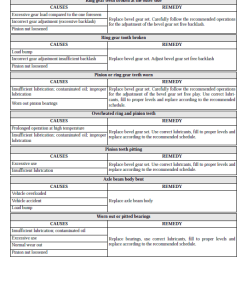

- Bevel Gear Shaft and Steering System – Detailed inspection and assembly instructions.

- Final Drive – Maintenance and operational instructions for the final drive components.

- Undercarriage (Track Group) – Insights into track group sections and maintenance.

- Steering Control System – Instructions on managing and controlling the steering system.

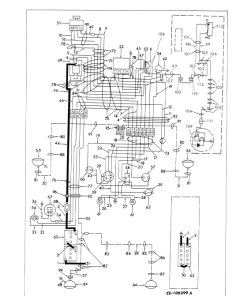

- Electrical System – Guidelines for inspecting and maintaining the electrical elements.

- Work Attachments – Overview of work attachment integration and control.

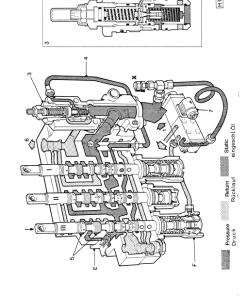

- Hydraulic Systems – Detailed manual for managing hydraulic operations and components.

Key Features

- Comprehensive guidance for machinery maintenance.

- Detailed instructions on disassembly and assembly.

- Coverage of hydraulic and electrical systems.

- Insights on adjustment inspections post-assembly.

Benefits

- Ensures safe and efficient maintenance operations.

- Facilitates accurate reassembly with step-by-step instructions.

- Minimizes machine downtime with precise inspection guidelines.

- Improves machine longevity and performance through regular maintenance insights.

Usage Recommendations

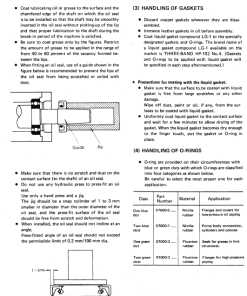

- Always use appropriate safety gear when servicing machinery components.

- Follow sequence in the table of contents for systematic inspection and assembly.

- Ensure all removed components, such as tubes, are appropriately tagged and stored to prevent contamination.

- Regularly refer to the manual for guidance on specific part maintenance to avoid errors.

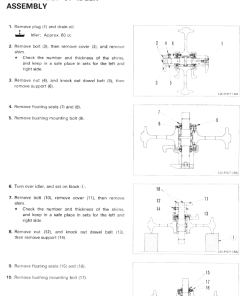

Instructions for Torque Converter Assembly

To effectively remove the torque converter assembly, follow these steps:

- First, remove the floor plate and the torque converter under guard.

- Disconnect the following tubes at the torque converter side:

- Tube from the torque converter regulator valve outlet to the oil cooler inlet.

- Tube from the TOROFLOW transmission control valve outlet to the torque converter relief valve inlet.

- Tube from the torque converter relief valve outlet to the TOROFLOW transmission lubricating oil relief valve inlet.

- Tube from the torque converter case to the bevel gear shaft case.

- Torque converter lubricating oil tube from the TOROFLOW transmission case to the torque converter case.

- Tube for torque converter oil pressure gauge.

- Tube for torque converter oil temperature gauge.

- Ensure all tubes are removed to prevent contamination. Use cables to sling the torque converter, securing them to the eyebolts on the case.

- Remove the coupling and unscrew 15 bolts fastening the torque converter case to the flywheel case, and one stud nut.

- Carefully move the torque converter assembly towards the transmission until the gear mesh disengages, then set it down off the”, “

Only logged in customers who have purchased this product may leave a review.

Related products

$34.00

Caterpillar CAT CS-683E Vibratory Compactor Service Repair Manual (AGR00001 and up)

Caterpillar CAT CS-683E Vibratory Compactor Service Repair Manual (AGR00001 and up)

Reviews

There are no reviews yet.