Komatsu D65EX-17, D65PX-17, D65WX-17 Dozer Service Manual

$36.00

This comprehensive full-service manual is essential for the maintenance and repair of Komatsu Dozers. Including 1,848 pages of detailed instructions, it covers the D65EX-17, D65PX-17, and D65WX-17 models.

Comprehensive Shop Manual

Product Overview

This detailed shop manual is an essential resource for professionals performing maintenance and repair services in a workshop. It is meticulously organized into various sections to facilitate a systematic approach to understanding, testing, and troubleshooting machinery components. The manual is designed to be an indispensable guide for smooth and efficient maintenance operations.

Table of Contents

- Index and Foreword: Introducing general information and the structure of this comprehensive guide.

- Specification: Detailed technical data and specifications of the machine.

- Structure, Function, and Maintenance Standard: Insights into the engine, cooling system, power train, and more. This section details the architecture, function, and standard maintenance practices.

- Standard Value Table: Essential values for new machines and criteria for assessments during testing and troubleshooting.

- Testing and Adjusting: Testing methodologies, tools, and adjustment techniques for various parts.

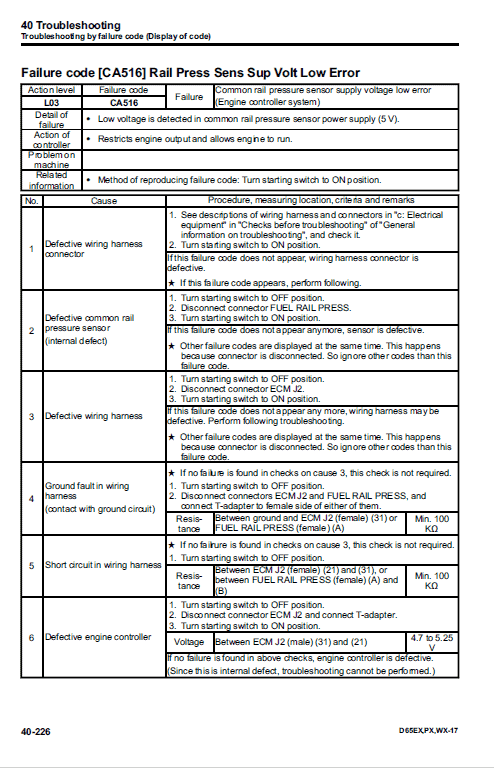

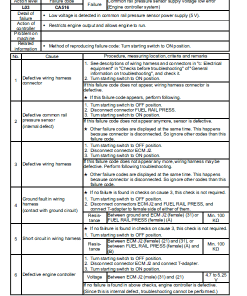

- Troubleshooting: Identifying and repairing faulty parts categorized by failure modes.

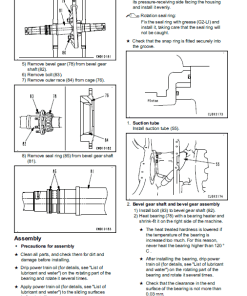

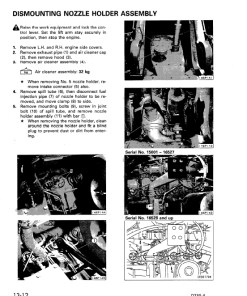

- Disassembly and Assembly: Instructions on removing, installing, and caring for each component using specialized tools.

- Maintenance Standard: Criteria and solutions for disassembly and services, with maintenance benchmarks.

- Appendix: Additional equipment specifications not covered in other sections.

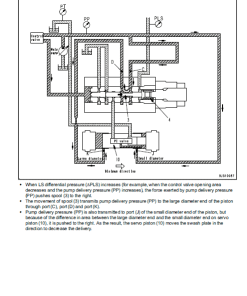

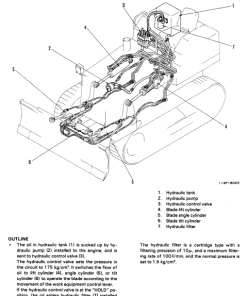

- Diagrams and Drawings: Includes hydraulic and electrical circuit diagrams for comprehensive insights.

Key Features

- Clear indexing and forewords for guided navigation.

- In-depth specifications and technical data.

- Maintenance standards for extended equipment lifespan.

- User-friendly troubleshooting guidelines.

- Detailed diagrams supporting practical applications.

Benefits

- Enhances understanding of machinery components and their functions.

- Facilitates effective troubleshooting and problem-solving strategies.

- Promotes efficient maintenance and service operations.

- Ensures accuracy and precision in technical assessments and repairs.

Usage Recommendations

- Begin with the Index and Foreword for a structured approach.

- Consult the Specification and Structure sections before initiating repairs.

- Regularly refer to the Standard Value Table for accurate testing and adjustments.

- Follow the Troubleshooting section to effectively pinpoint and rectify issues.

- Use the diagrams as a reference for visual clarity during complex procedures.

General Information on Troubleshooting

Troubleshooting aims to identify the root cause of a failure, execute swift repairs, and prevent repeat occurrences. Understanding the structure and function is crucial, yet engaging with operators for insights often leads to efficient problem resolution. Here are some key steps to consider:

Important Troubleshooting Guidelines

- Refrain from Immediate Disassembly: Avoid dismantling components impulsively after a failure to prevent unnecessary work and loss of resources. This approach helps maintain user confidence.

- Inquire with Users or Operators:

- Inquire about any other issues or unusual machine behavior before failure.

- Determine if the failure was sudden or if pre-existing conditions existed.

- Clarify the failure context and any prior repairs conducted.

- Pre-Troubleshooting Checks:

- Inspect for abnormal symptoms in the machine.

- Conduct thorough checks prior to starting daily operations.

- Ensure regular maintenance items are scrutinized.

- Confirm Failure: Directly assess failure severity and differentiate between actual breakdowns and operator handling errors. Avoid actions that might exacerbate the issue during reenactment.

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.