Komatsu Galeo D51EX-22, D51PX-22 Dozer Service Manual

Product Overview

This comprehensive service manual is an essential resource for maintaining and servicing the Komatsu Galeo D51EX-22 and D51PX-22 dozers. It includes detailed information about machine specifications, maintenance standards, and procedural guides for troubleshooting and repairs. The manual is structured into specific sections to facilitate easy navigation and understanding.

Key Features

- General Specifications: Dimensions, performance metrics, component weights, and fluid specifications.

- Structural Insights: Detailed explanation of each component’s design and function, alongside maintenance standards.

- Testing and Adjustment Protocols: Procedures for pre- and post-repair checks and necessary adjustments.

- Troubleshooting Guides: Comprehensive charts correlating common problems with their causes.

- Disassembly and Assembly Instructions: Step-by-step guidance for removing, installing, disassembling, and assembling components with safety precautions.

- Supplementary Information: Foldout machine drawings to assist with repairs and understanding component layout.

Benefits

- Ensures optimal performance and longevity of the dozer through detailed maintenance instructions.

- Enhances user understanding of machine mechanics, aiding in efficient troubleshooting and repair.

- Structured format aids in quick referencing and guided procedures.

Usage Recommendations

- Regularly consult the general specifications to maintain machine performance and efficiency.

- Follow the structural guides for routine inspections and understanding of component functionality.

- Leverage the troubleshooting charts to promptly identify and resolve issues.

- Methodically adhere to the disassembly and assembly instructions to prevent component damage.

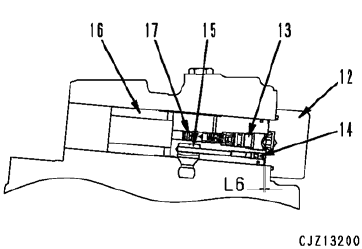

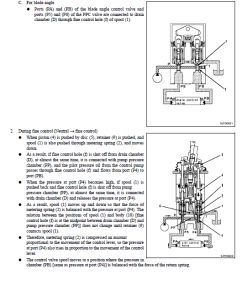

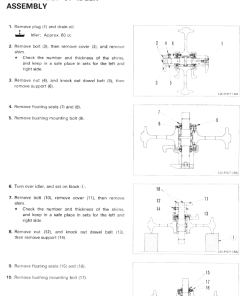

Assembly of Main Piston

- Install spool (17) onto piston (16).

- Place O-ring on plug (13) and install it into piston (16).

- Fit O-ring onto piston assembly (16) and secure it to the end cover.

- Install pin (15) and secure with screw (14).

- Ensure proper orientation of pin (15).

- Verify dimension (L6) to ensure screw (14) is correctly positioned in pin (15) hole.

- Degrease threaded areas of the screw and piston using trichloroethylene, dry them, and apply two drops of adhesive (0.04 g) to each.

- After tightening, avoid oil application for at least one hour to allow LOCTITE to harden.

- Avoid applying pressure for at least six hours after tightening.

Only logged in customers who have purchased this product may leave a review.

Related products

$34.00

$33.50

$33.50

Reviews

There are no reviews yet.