-

×

Hyundai R55W-7A Wheel Excavator Service Repair Manual

$34.00

Hyundai R55W-7A Wheel Excavator Service Repair Manual

$34.00 -

×

Hyundai HX55A CR Crawler Excavator Service Repair Manual

$34.00

Hyundai HX55A CR Crawler Excavator Service Repair Manual

$34.00 -

×

Hyundai R330LC-9A Crawler Excavator Service Repair Manual

$35.00

Hyundai R330LC-9A Crawler Excavator Service Repair Manual

$35.00 -

×

Hyundai HX160 L, HX180 L Crawler Excavator Service Repair Manual

$35.00

Hyundai HX160 L, HX180 L Crawler Excavator Service Repair Manual

$35.00 -

×

Hyundai HX300 L Crawler Excavator Service Repair Manual

$36.00

Hyundai HX300 L Crawler Excavator Service Repair Manual

$36.00 -

×

Hyundai HX500A L Crawler Excavator Service Repair Manual

$34.00

Hyundai HX500A L Crawler Excavator Service Repair Manual

$34.00 -

×

Hyundai HX35A Z Crawler Excavator Service Repair Manual

$34.00

Hyundai HX35A Z Crawler Excavator Service Repair Manual

$34.00 -

×

Hyundai R27Z-9 Crawler Excavator Service Repair Manual

$34.00

Hyundai R27Z-9 Crawler Excavator Service Repair Manual

$34.00 -

×

Hyundai HX480S L, HX520S L Crawler Excavator Service Repair Manual

$35.00

Hyundai HX480S L, HX520S L Crawler Excavator Service Repair Manual

$35.00 -

×

Hyundai R130S (Smart+) Crawler Excavator Service Repair Manual (Built in India)

$34.00

Hyundai R130S (Smart+) Crawler Excavator Service Repair Manual (Built in India)

$34.00 -

×

Hyundai R320LC-3 Crawler Excavator Service Repair Manual

$34.00

Hyundai R320LC-3 Crawler Excavator Service Repair Manual

$34.00 -

×

Hyundai HX17A Z Crawler Excavator Service Repair Manual

$34.00

Hyundai HX17A Z Crawler Excavator Service Repair Manual

$34.00 -

×

Hyundai R180LC-7 Crawler Excavator Service Repair Manual

$34.00

Hyundai R180LC-7 Crawler Excavator Service Repair Manual

$34.00 -

×

Hyundai HX300HD Crawler Excavator Service Repair Manual

$34.00

Hyundai HX300HD Crawler Excavator Service Repair Manual

$34.00 -

×

Hyundai R450LC-7 Crawler Excavator Service Repair Manual

$35.00

Hyundai R450LC-7 Crawler Excavator Service Repair Manual

$35.00 -

×

Hyundai HX300LT3 Crawler Excavator Service Repair Manual

$34.00

Hyundai HX300LT3 Crawler Excavator Service Repair Manual

$34.00 -

×

Hyundai HX430 L Crawler Excavator Service Repair Manual

$35.00

Hyundai HX430 L Crawler Excavator Service Repair Manual

$35.00 -

×

Hyundai R220LC-9S Crawler Excavator Service Repair Manual (Built in Brazil)

$35.00

Hyundai R220LC-9S Crawler Excavator Service Repair Manual (Built in Brazil)

$35.00 -

×

Hyundai HX260 L Crawler Excavator Service Repair Manual

$35.00

Hyundai HX260 L Crawler Excavator Service Repair Manual

$35.00 -

×

Hyundai R180LC-3 Crawler Excavator Service Repair Manual

$34.00

Hyundai R180LC-3 Crawler Excavator Service Repair Manual

$34.00 -

×

Hyundai R170W-7A Wheel Excavator Service Repair Manual

$35.00

Hyundai R170W-7A Wheel Excavator Service Repair Manual

$35.00 -

×

Hyundai R140LC-7 Crawler Excavator Service Repair Manual

$34.00

Hyundai R140LC-7 Crawler Excavator Service Repair Manual

$34.00 -

×

Hyundai R140LC-9V Crawler Excavator Service Repair Manual (Built in India)

$34.00

Hyundai R140LC-9V Crawler Excavator Service Repair Manual (Built in India)

$34.00 -

×

Hyundai R260LC-9S Crawler Excavator Service Repair Manual (Built in Brazil)

$34.00

Hyundai R260LC-9S Crawler Excavator Service Repair Manual (Built in Brazil)

$34.00 -

×

Hyundai R145CR-9 Crawler Excavator Service Repair Manual

$34.00

Hyundai R145CR-9 Crawler Excavator Service Repair Manual

$34.00 -

×

Hyundai R360LC-7 Crawler Excavator Service Repair Manual

$34.00

Hyundai R360LC-7 Crawler Excavator Service Repair Manual

$34.00 -

×

Hyundai HX1000L Crawler Excavator Service Repair Manual

$35.00

Hyundai HX1000L Crawler Excavator Service Repair Manual

$35.00 -

×

Hyundai R380LC-9SH Crawler Excavator Service Repair Manual

$35.00

Hyundai R380LC-9SH Crawler Excavator Service Repair Manual

$35.00 -

×

Hyundai R140W-7A Wheel Excavator Service Repair Manual

$35.00

Hyundai R140W-7A Wheel Excavator Service Repair Manual

$35.00 -

×

Hyundai R370LC-7 Crawler Excavator Service Repair Manual

$34.00

Hyundai R370LC-7 Crawler Excavator Service Repair Manual

$34.00 -

×

Hyundai R55-7A Crawler Excavator Service Repair Manual

$34.00

Hyundai R55-7A Crawler Excavator Service Repair Manual

$34.00 -

×

Hyundai R140W-7 Wheel Excavator Service Repair Manual

$35.00

Hyundai R140W-7 Wheel Excavator Service Repair Manual

$35.00 -

×

Hyundai R140LC-9A Crawler Excavator Service Repair Manual

$34.00

Hyundai R140LC-9A Crawler Excavator Service Repair Manual

$34.00 -

×

Hyundai R800LC-7A Crawler Excavator Service Repair Manual

$34.00

Hyundai R800LC-7A Crawler Excavator Service Repair Manual

$34.00 -

×

Hyundai R145CR-9A Crawler Excavator Service Repair Manual

$34.00

Hyundai R145CR-9A Crawler Excavator Service Repair Manual

$34.00

Komatsu HM400-3R Dump Truck Service Repair Manual

$44.00

Discover comprehensive guidance with the Komatsu HM400-3R Dump Truck Shop Manual. This manual includes detailed specifications and information across 2314 pages.

SKU: 313259

Categories: Dump Truck, Komatsu

Komatsu Shop Manual Guide

Product Overview

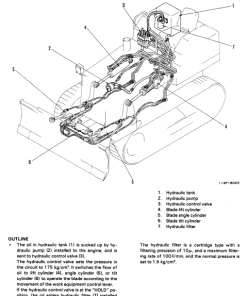

The Komatsu Shop Manual is an essential resource for service workshops, providing detailed technical information required for maintaining and repairing Komatsu machinery. This comprehensive manual is designed for both machine and engine parts, offering invaluable insights into the machinery’s operation, components, and maintenance procedures. Please note that certain attachments and options discussed in this manual may vary by region. For specific needs, it’s advisable to consult your local Komatsu distributor.

Key Features

- Comprehensive Coverage: Includes detailed information for both machine and engine parts.

- Structured Format: Divided into clear sections to aid in easy navigation and understanding.

- Updated Specifications: Information may be subject to change without prior notice to ensure accuracy and relevance.

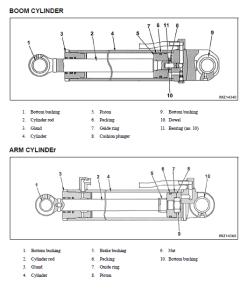

- Illustrations and Diagrams: Contains typical model images and circuit diagrams for clarity.

Benefits

- Efficiency in Troubleshooting: Offers a thorough understanding of component structure and operation, assisting in effective troubleshooting.

- Guidance on Maintenance: Provides standard values and detailed instructions for maintenance, ensuring machinery longevity.

- Enhanced Safety: Lists safety precautions and procedures for disassembly and assembly, promoting secure operations.

Usage Recommendations

- Consultation: For specific attachments and regional options, contact your local Komatsu distributor.

- Reference the Correct Section: Use the structured chapters to find relevant information quickly.

- Verify Details Regularly: Check for updates in specifications and procedures that may have changed.

Manual Composition

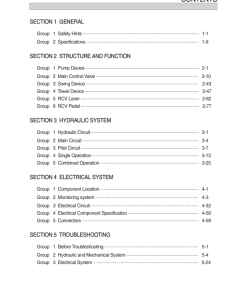

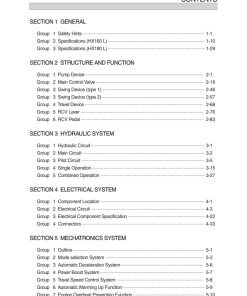

- 00 INDEX AND FOREWORD: Introduction including index, safety, and essential information.

- 01 SPECIFICATIONS: Detailed machine specifications section.

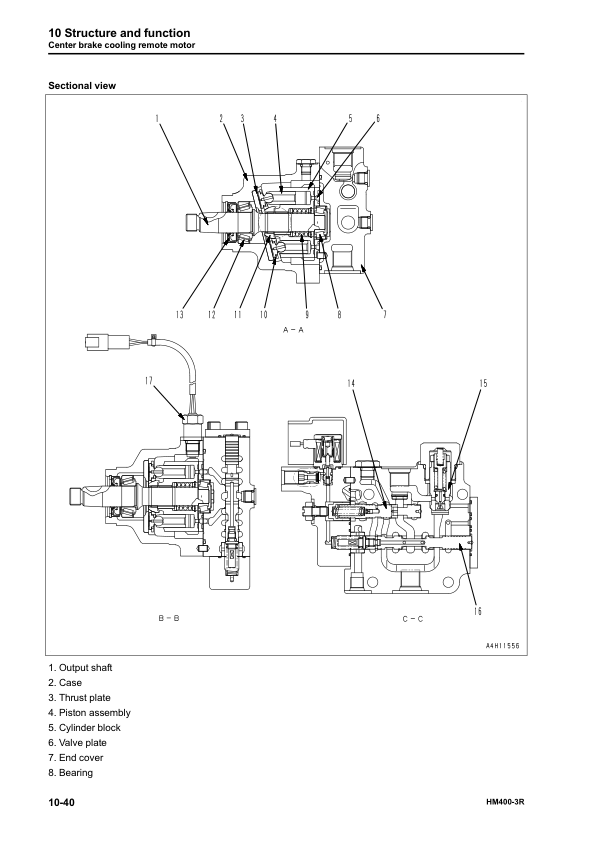

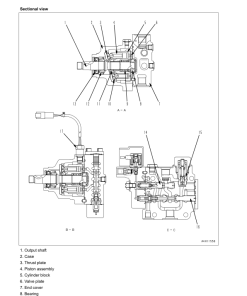

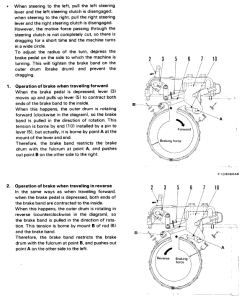

- 10 STRUCTURE AND FUNCTION: In-depth look at the structure and operation of components.

- 20 STANDARD VALUE TABLE: Provides standard operating values for testing and troubleshooting.

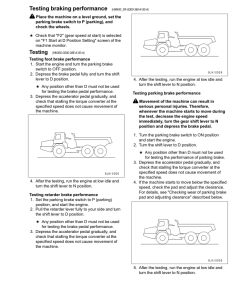

- 30 TESTING AND ADJUSTING: Guidelines for measuring tools, methods, and adjustments of parts.

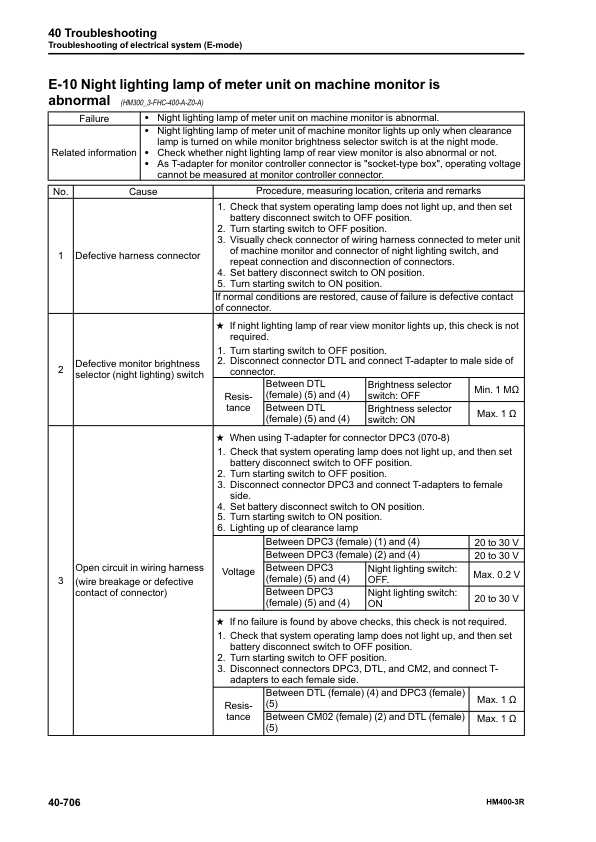

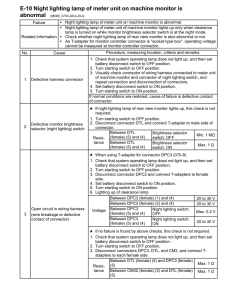

- 40 TROUBLESHOOTING: Failure diagnostics and solution methods organized by failure mode.

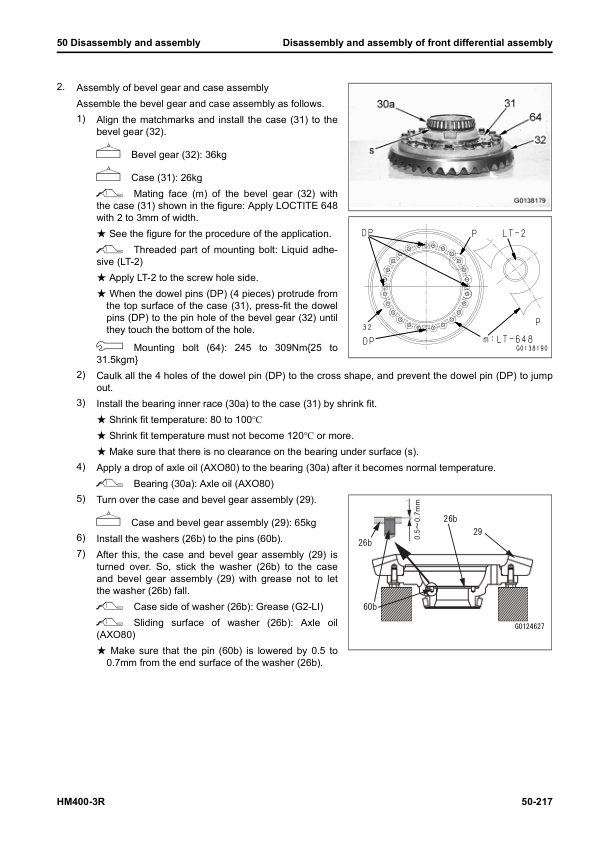

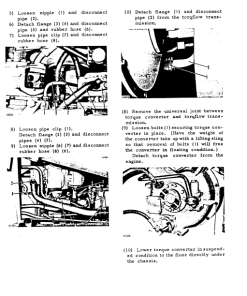

- 50 DISASSEMBLY AND ASSEMBLY: Special tools and procedures for component handling.

- 60 MAINTENANCE STANDARD: Criteria and remedies for proper maintenance practices.

- 80 OTHER INFORMATION: Covers miscellaneous procedures and equipment details.

- 90 Circuit Diagrams: Hydraulic and electrical diagrams for detailed reference.

Only logged in customers who have purchased this product may leave a review.

Related products

$34.50

$34.00

$27.50

Reviews

There are no reviews yet.