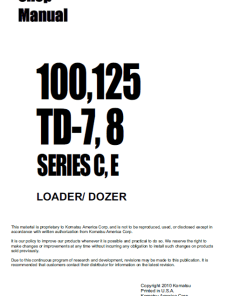

Excavator Shop Manual

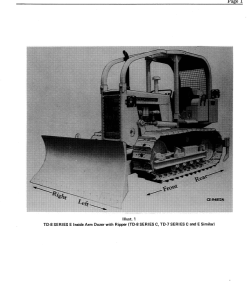

Product Overview

This comprehensive shop manual is an essential resource for anyone conducting technical services on an Excavator within a workshop setting. To facilitate ease of use and understanding, the manual is systematically organized into key sections, each focusing on specific aspects related to the Excavator’s maintenance and operation.

Contents Overview

- 01. General: Detailed machine specifications for the Excavator.

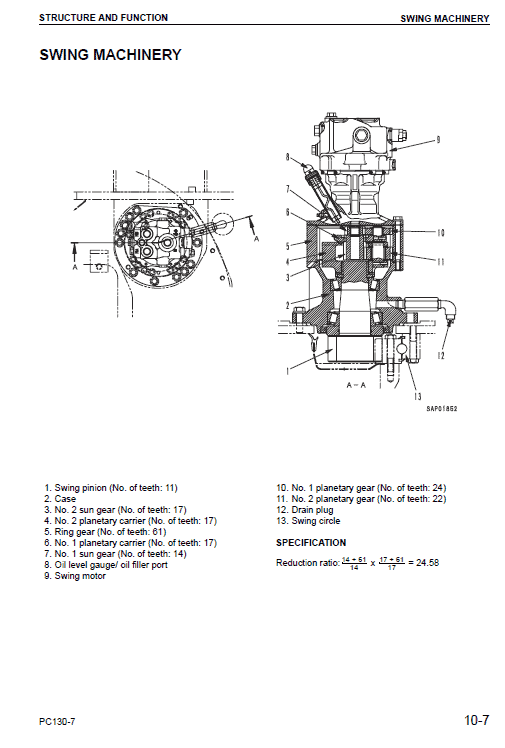

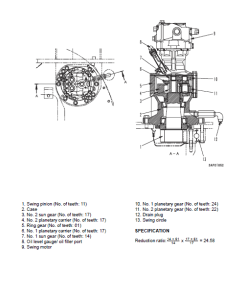

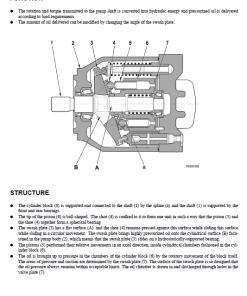

- 10. Structure and Function, Maintenance Standard: Insights into component structure, functional understanding, troubleshooting, and maintenance criteria.

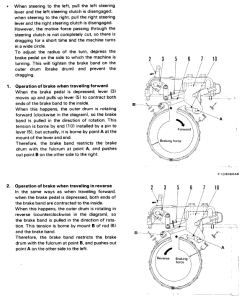

- 20. Testing and Adjusting: Guidance on standard values, measurement methods, adjustments, and part testing.

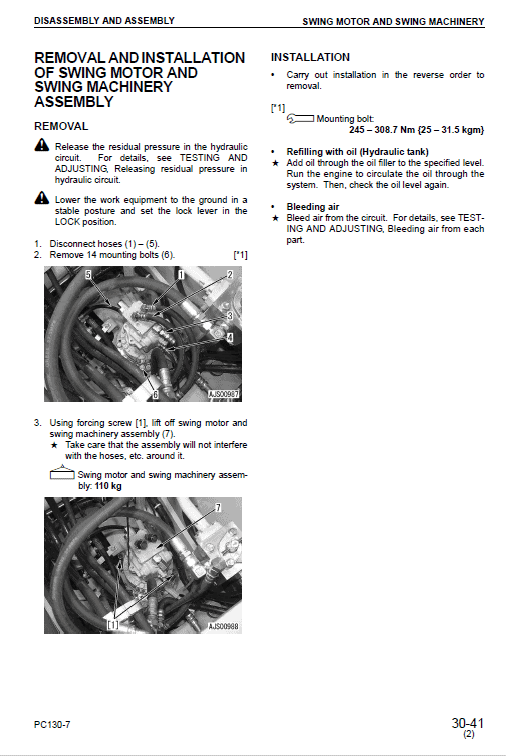

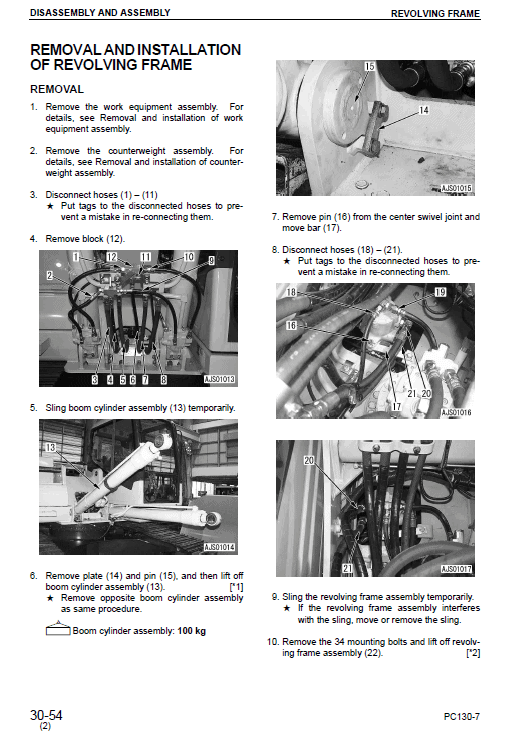

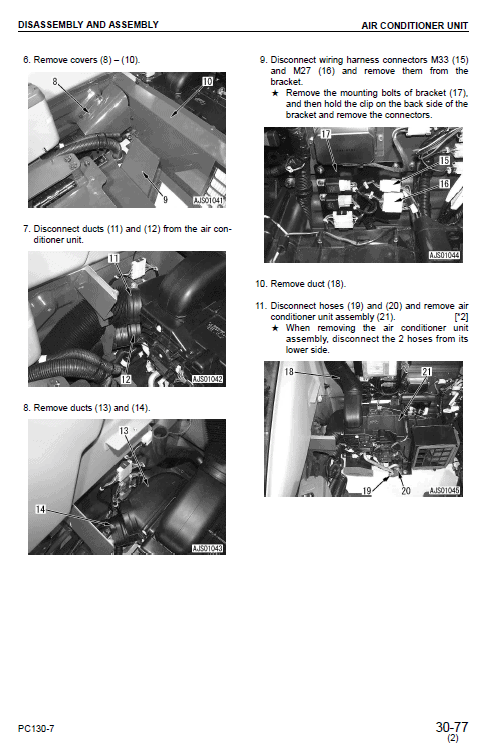

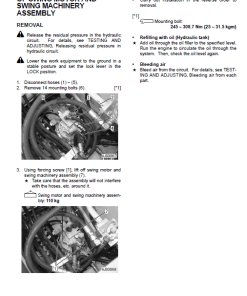

- 30. Disassembly and Assembly: Instructions on tools and procedures for component removal and reassembly, including material requirements.

- 40. Maintenance Standard: Standards for inspecting and evaluating disassembled parts.

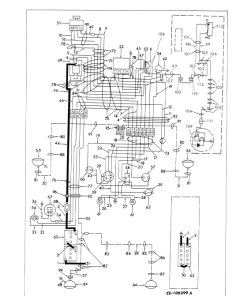

- 90. Others: Additional details including hydraulic and electrical circuit diagrams. Methods for part repair and replacement.

Key Features

- Comprehensive Specifications: In-depth technical specifications to understand the Excavator.

- Detailed Structural Insights: Explains the structure and functions of various components for easier troubleshooting.

- Standard Values and Testing: Clarifies the testing criteria and adjustment principles using standard value tables.

- Assembly & Disassembly Guidance: Step-by-step instructions for efficient assembly and disassembly, with necessary equipment details.

Benefits

- Easy Troubleshooting: Organized sections help identify and repair failed components effectively.

- Standardized Procedures: Provides consistent procedures aligning with industry best practices.

- Resource Efficiency: Maximizes resource utilization by detailing quantities and specifications of required materials.

Usage Recommendations

- Consult for Maintenance: Utilize the manual for regular maintenance and standards adherence in workshop services.

- Reference for Troubleshooting: Use the troubleshooting sections split by failure modes for effective issue resolution.

- Follow Detailed Procedures: Adhere to outlined procedures for safe and accurate assembly and disassembly.

- Check Standard Values Regularly: Ensure regular testing and adjusting in line with the standard value tables.

Testing and Adjusting Fan Belt Tension

- Open the engine hood and remove the belt cover from above the alternator.

- Press the intermediate point of the belt between the fan pulley and alternator pulley with a finger and measure the deflection.

- Required force to press the belt: Approx. 58.8 N (6 kg), Deflection: 6-10 mm.

Only logged in customers who have purchased this product may leave a review.

Related products

$34.00

$33.50

John Deere 401C Backhoes Parts Catalog Manual - PC1431

John Deere 401C Backhoes Parts Catalog Manual - PC1431

Reviews

There are no reviews yet.