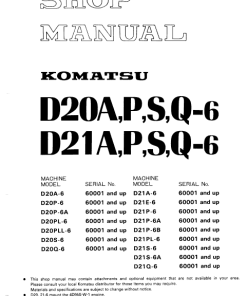

Shop Manual for Excavators

Product Overview

This comprehensive shop manual provides essential technical information required for servicing and maintaining excavators. Structured for clarity, it ensures that workshop processes are well-understood by dividing the manual into distinct sections, each focusing on critical aspects of the machinery.

Key Features

- Foreword: An introduction that covers essential safety precautions and foundational information.

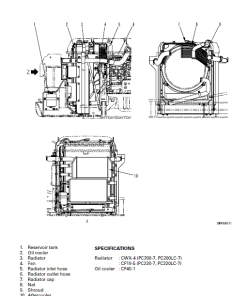

- General: Details the complete specifications of the excavator.

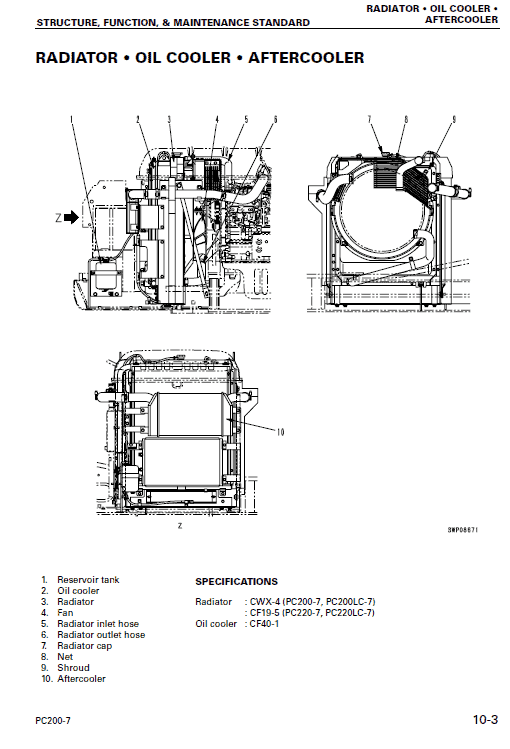

- Structure and Function, Maintenance Standard: Offers detailed explanations of each component’s structure, function, and maintenance standards, serving as a valuable resource for troubleshooting.

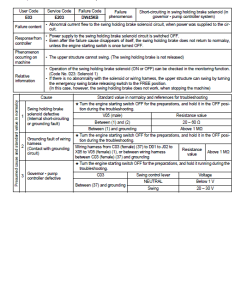

- Testing and Adjusting: Provides standard value tables, measurement methods, and adjustment procedures. It is crucial for evaluating components during testing, adjusting, and troubleshooting.

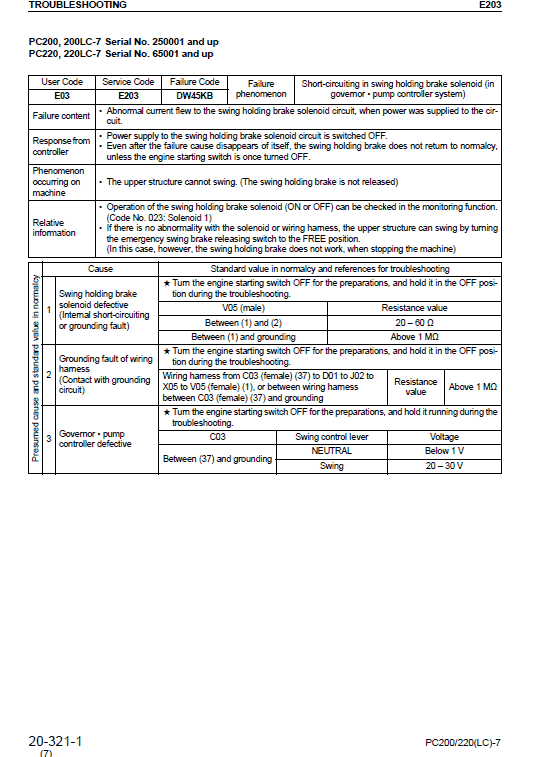

- Troubleshooting: Step-by-step instructions for diagnosing and repairing faults. Includes guidance on engine-related issues and references to chassis and engine volumes as necessary.

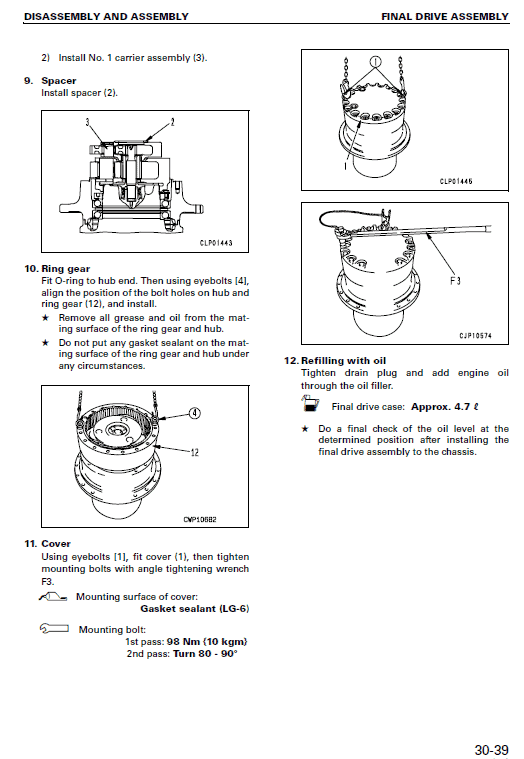

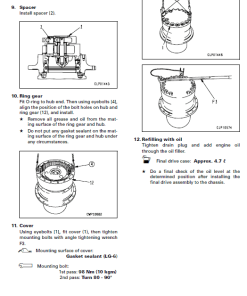

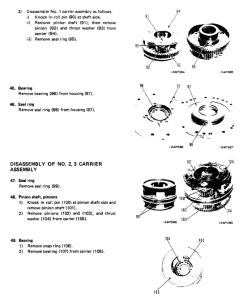

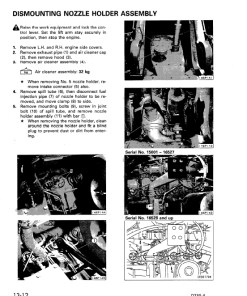

- Disassembly and Assembly for Excavator: Detailed procedures for the removal, installation, disassembly, and assembly of components, including necessary tools and precautions.

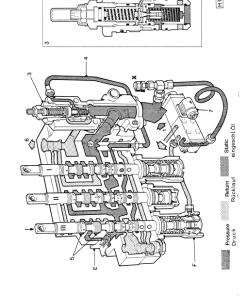

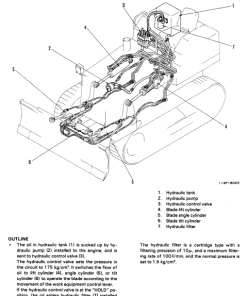

- Others – Chassis and Engine Volumes: Includes hydraulic and electrical circuit diagrams (Chassis) as well as repair and replacement methods (Engine).

Benefits

- Ensures safe and efficient servicing of excavator equipment.

- Clear and methodical presentation enhances understanding and workflow efficiency.

- Covers a broad range of topics from basic safety to complex troubleshooting.

- Provides essential specifications and standard measurements for accurate maintenance.

Usage Recommendations

- Utilize this manual as the primary resource for technical service and maintenance tasks.

- Refer to specific sections for troubleshooting and diagnosis of equipment issues.

- Follow the detailed procedures for disassembly and assembly to ensure precise and safe operations.

- Consult the hydraulic and electrical circuit diagrams for comprehensive repair and replacement tasks.

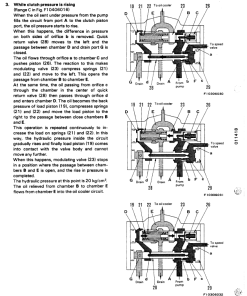

Inspection of PPC Valve

To inspect the PPC valve, measure the hydraulic drift of the work equipment while the accumulator is pressurized. Ensure the control lever operates correctly in both LOCK and FREE positions. If there is a difference between these positions, the PPC valve may have an internal failure, requiring attention.

- Operate the control with the engine switch in the ON position.

- If pressure falls, run the engine for approximately 10 seconds to recharge the accumulator.

- Analyze for any discrepancies in hydraulic drift between LOCK and FREE positions.

Only logged in customers who have purchased this product may leave a review.

Related products

$33.00

$34.00

$32.50

Komatsu PC130F-7 Excavator Repair Service Manual

Komatsu PC130F-7 Excavator Repair Service Manual  Komatsu PC360LCi-11, PC390LCi-11 Excavator Repair Service Manual

Komatsu PC360LCi-11, PC390LCi-11 Excavator Repair Service Manual  Komatsu PC75UU-2 Excavator Service Manual

Komatsu PC75UU-2 Excavator Service Manual  Komatsu PC80MR-3 Excavator Service Manual

Komatsu PC80MR-3 Excavator Service Manual

Reviews

There are no reviews yet.