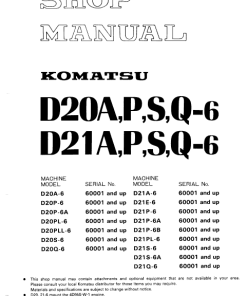

Comprehensive Maintenance Manual

Product Overview

This comprehensive maintenance manual is an essential resource for understanding and performing maintenance on various mechanical systems. Designed for professional technicians and engineers, it provides detailed instructions, diagrams, and procedures to ensure proper maintenance and functionality of equipment.

Table of Contents

- Index and Foreword

- Specification

- Structure, Functions, Maintenance Standard

- Standard Value Table

- Testing and Adjusting

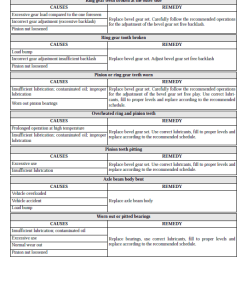

- Troubleshooting

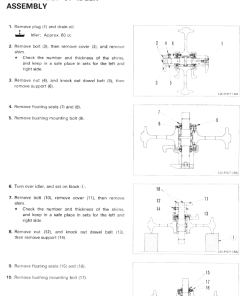

- Disassembly and Assembly

- Diagrams and Drawings

Manual Extract Precautions

Precautions for Installation Work

Ensure a successful and safe installation by following these critical precautions:

- Tighten all bolts and nuts (including sleeve nuts) to the specified torque (KES).

- Install hoses without twisting or interference and secure them with intermediate clamps, if available.

- Always replace gaskets, O-rings, cotter pins, and lock plates with new components.

- Bend cotter pins and lock plates securely to ensure stability.

- For adhesive applications, clean and degrease the relevant part, and apply two to three drops of adhesive to the threaded section.

- When using a liquid gasket, clean and degrease the surface, ensuring it is free from dirt or damage, before applying uniformly.

- Clean all parts and address any damage, dents, burrs, or rust.

- Coat rotating and sliding parts with engine oil for smooth operation.

- Apply molybdenum disulfide lubricant (LM-P) to surfaces during press-fitting operations.

- Verify that snap rings settle completely within their grooves after installation.

- Thoroughly clean wiring connectors to remove oil, dirt, or water, ensuring a secure connection.

- Inspect eyebolts for deterioration or deformation, ensure they are fully screwed in, and align the hook direction appropriately.

- Fasten split flanges uniformly and alternately to avoid excessive tightening on one side.

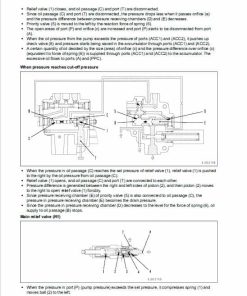

Hydraulic System Air Bleeding Recommendations

After reassembling cylinders, hydraulic pumps, and other components post-repair, bleed air as follows:

- Start and run the engine at low idle.

- Operate the hydraulic cylinder control lever and stop 100 mm before the stroke’s end. Repeat this process four to five times.

- Then, operate the hydraulic cylinder completely to the end of its stroke three to four times to ensure all air is expelled.

Only logged in customers who have purchased this product may leave a review.

Related products

$34.00

$34.00

$33.50

John Deere 550A, 555A Crawler Bulldozer Loader Technical Manual

John Deere 550A, 555A Crawler Bulldozer Loader Technical Manual  John Deere 555 Crawler Loader Repair Technical Manual (TM1111)

John Deere 555 Crawler Loader Repair Technical Manual (TM1111)

Reviews

There are no reviews yet.